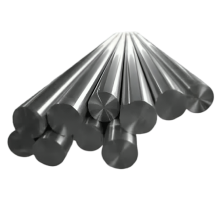

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Length :

1 To 6 Meters, Custom Cut Length

Thickness :

50 mm to 6000 mm Long

SS 440C Round Bars are martensitic stainless steel components with a high carbon content, engineered for superior surface hardness, excellent abrasion resistance, and reliable mechanical strength even at elevated temperatures. Comprising approximately 1.0 - 1.2% carbon and 16 - 18% chromium, SS 440C achieves remarkable mechanical strength after heat treatment. This grade can be hardened to Rockwell C60 and higher, making it one of the hardest stainless steels available in bar or rod form. The alloy also contains minor amounts of manganese, silicon, and molybdenum, contributing to its superior corrosion resistance under mild atmospheric and oxidizing environments.

These round bars and rods exhibit excellent dimensional stability post hardening, alongside good machinability in the annealed condition. They are typically supplied in quenched and tempered states, ensuring an optimal balance of toughness and rigidity. Surface finishes such as bright, black, peeled, or polished are available depending on end-use requirements. Their microstructure - predominantly martensitic - allows for precise grinding and lapping, particularly useful in applications where dimensional tolerances are critical. Furthermore, the alloy’s ability to resist deformation under mechanical stress makes SS 440C a preferred choice for precision-engineered components.

Crafted to exacting quality benchmarks, 440C stainless steel round bars and rods meet and exceed the stringent requirements of ASTM A276 and ASTM A484 standards. Common diameters range from 4 mm to 200 mm, with custom sizes available upon request. We cater to the quality needs of clients primarily across India, the United Arab Emirates (UAE), and the Kingdom of Saudi Arabia (KSA), ensuring prompt availability and consistent supply across a wide range of industrial sectors.

Applications of SS 440C Round Bars & Rods

SS 440C Round Bars and Rods are extensively utilized in applications that demand a unique combination of high strength, hardness, and moderate corrosion resistance. They are particularly valuable in the manufacture of components that must endure abrasive conditions while maintaining precision over time. These include bearings, valve components, surgical instruments, and high-load mechanical parts. Their ability to maintain edge retention and resist galling makes them ideal for knife blades, ball bearings, and rolling elements in bearing assemblies.

In the fields of mechanical engineering and precision tooling, SS 440C rods are widely utilized for crafting components such as punches, shafts, gauges, and die sets due to their outstanding hardness and dimensional stability. Their high hardness allows for prolonged tool life and reduced wear under repetitive motion and load-bearing conditions. They are also widely used in the production of aerospace components and turbine parts where high fatigue strength and dimensional consistency are critical. Thanks to their compatibility with heat treatment processes like quenching and tempering, SS 440C components can be custom-hardened to meet specific performance requirements, a feature that significantly expands their application versatility.

Additionally, SS 440C Round Bars serve as an excellent material choice for components operating in moderately corrosive environments such as marine hardware, food processing equipment, and pharmaceutical machinery. Although not as corrosion-resistant as austenitic grades, their superior mechanical properties provide a compelling trade-off in applications where strength and wear resistance are prioritized over chemical stability. They are also widely used in the defense sector for parts requiring both toughness and rigidity under dynamic stresses.

Industry Use and Regional Supply Expertise

SS 440C Round Bars and Rods are integral to a range of high-performance industries that rely on material precision, structural integrity, and long-term reliability. In the automotive industry, they are used in transmission components, clutch assemblies, and engine parts, where high wear resistance is essential. Aerospace manufacturers value their dimensional stability and fatigue resistance for producing gear parts, actuator rods, and control system components. Medical device manufacturers favor SS 440C for crafting surgical tools, dental instruments, and orthopedic implants due to its excellent hardness and the ability to retain a sharp edge over time.

In the oil and gas industry, SS 440C is a material of choice for downhole tools, valve trim parts, and drilling equipment, owing to its superior mechanical strength and resistance to abrasion in high-pressure environments. Defense and military sectors deploy this alloy in the manufacture of weaponry, projectile parts, and structural armor elements. Even renewable energy sectors, such as wind and hydroelectric power, integrate SS 440C rods in gearboxes and wear-intensive components. These industries demand reliability, and SS 440C delivers with unmatched resilience and long service life.

As a dependable supplier across India, the UAE, and the Kingdom of Saudi Arabia (KSA), we deliver SS 440C Round Bars and Rods with unmatched consistency, customized precisely to meet the technical demands of diverse industry sectors. Our supply chain is designed to support time-critical projects with consistent quality and documentation. We cater to a diverse client base, ranging from small-scale engineering workshops to multinational OEMs and EPC contractors. With decades of experience in material sourcing and logistics, we understand regional compliance standards, making us a preferred partner for bulk orders and long-term procurement contracts. Whether for rapid prototyping or full-scale production, our supply expertise ensures clients receive materials that meet the highest global standards.

| STANDARD | UNS | WNR. |

|---|---|---|

| SS 440C | S44004 | 1.4125 |

SS 440C Square Bar

Stainless Steel 440C Square Bar, UNS S44004 Square Bar, DIN 1.4125 Square Rod, ASME SA 276 SS 440C Square Bar, Stainless Steel 440C Polish Square Bar, SS 440C Square Rod

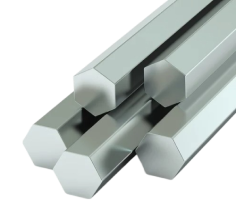

SS 440C Hex Bar

ASME SA276 SS 440C Hex Bar, ASTM A276 Stainless Steel 440C Hex Bar, DIN 1.4125 Hex Bar, UNS S44004 Hex Bar, SS 440C Hex Rod, SS 440C Polish Hex Bar, SS 440C Hex Rod

SS 440C Rectangular Bar

Stainless Steel ASTM A276 440C Rectangular Bar, UNS S44004 / DIN 1.4125 Rectangular Bar, ASME SA276 SS 440C Rectangular Rod, SS 440C Rectangle Rod, Stainless 440C Rectangle Bar, Polish SS 440C Rectangular Bar Supplier

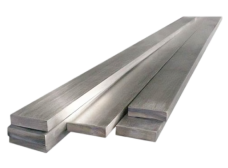

SS 440C Flat Bar

DIN 1.4125 Flat Bar, UNS S44004 Flat Bar, ASME SA 276 Stainless Steel 440C Flat Bar, ASTM A276 440C SS Flat Rod, SS 440C Polish Flat Bar

SS 440C Bright Bar

ASTM A276 440C Stainless Steel Bright Bar, SS UNS S44004 Bright Bar, SS 440C Bright Rod, SS 440C Polish Bright Bar

SS 440C Forged Bar

UNS S44004 Forged Bar, Stainless Steel 440C Forged Rod, ASTM A276 440C Stainless Steel Polish Forged Bar, ASME SA 276 SS 440C Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Length :

1 To 6 Meters, Custom Cut Length

Thickness :

50 mm to 6000 mm Long

Size :

14mm-300mm

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Chemical Composition of Stainless Steel 440C Round Bar

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 440C | 0.95 - 1.20 | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 16.00 - 18.00 | - |

Mechanical Properties Of Stainless Steel 440C Round Bar

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Rockwell (HR C) | Impact Charpy V (J) |

|---|---|---|---|---|---|

| Annealed* | 758 | 448 | 14 | 269HB max | - |

| 204 | 2030 | 1900 | 4 | 59 | 9 |

| 260 | 1960 | 1830 | 4 | 57 | 9 |

| 316 | 1860 | 1740 | 4 | 56 | 9 |

| 371 | 1790 | 1660 | 4 | 56 | 9 |

| * Annealed properties are typical for Condition A of ASTM A276# Brinell Hardness is ASTM A276 specified maximum for annealed 440C, B and C. | |||||

Physical Properties of 304/304L/304H SS Round Bar

Our SS 440C Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry