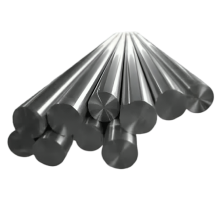

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 440A Round Bars are precision-engineered products made from high-carbon martensitic stainless steel, specifically classified under the 440 series. Characterized by a higher carbon content (approximately 0.65–0.75%), SS 440A delivers exceptional hardness, wear resistance, and moderate corrosion protection. This grade achieves superior mechanical strength through heat treatment processes such as hardening and tempering, enabling it to reach Rockwell hardness levels of up to 58 HRC, depending on the application. The alloy typically contains 16–18% chromium, which contributes to its corrosion resistance, and minimal amounts of nickel, ensuring a strong ferritic-martensitic structure ideal for applications where edge retention and toughness are required.

Produced through advanced hot rolling, cold drawing, or centerless grinding, SS 440A Round Bars and Rods offer excellent dimensional tolerance, surface finish, and machinability under controlled processing conditions. This material demonstrates a fine balance between high tensile strength and abrasion resistance, making it suitable for high-friction applications. While the corrosion resistance of SS 440A is lower compared to austenitic stainless steels, it performs reliably in mild industrial environments and is not prone to rapid degradation in dry or lightly humid conditions.

From a metallurgical standpoint, SS 440A maintains its structure well under thermal exposure and is known for its stability during quenching and tempering cycles. Although weldability is limited due to its high carbon content, careful welding techniques and post-weld heat treatment can be applied when structural integrity is essential. The round bars and rods are manufactured in a wide range of sizes and finishes—from hot-rolled and annealed to polished and hardened—making them suitable for both standard and highly customized engineering applications.

Applications

SS 440A Round Bars and Rods are specifically favored for components that require high surface hardness, excellent edge retention, and wear resistance. These properties make them ideal for producing industrial cutting tools, surgical instruments, and high-strength mechanical parts. In cutting tool manufacturing, SS 440A is widely used to create knife blades, shear blades, and die-cutting components where consistent sharpness and resistance to wear are essential over extended periods of use.

In the automotive and mechanical equipment sectors, these round bars are commonly machined into parts such as shafts, valve seats, pins, fasteners, and bushings. These components benefit from stainless steel round bars and rods 440A’s ability to resist galling, deformation, and fatigue under high-stress mechanical loads. The grade's hardness also makes it suitable for injection molding applications, where mold inserts and core pins are expected to withstand repeated mechanical stress and thermal cycling.

Additionally, SS 440A is utilized in the fabrication of high-precision components within the electronics and instrumentation industries. Its non-magnetic nature in the annealed state, coupled with excellent polishability and wear resistance, makes it ideal for producing measurement tools, calibration pins, and wear-resistant gauge parts. The material also finds use in agricultural machinery, where moving parts require high abrasion resistance against soil, gravel, and external impact, while maintaining form and function over long operational cycles.

Industry Use and Supply Reach

The industrial scope for SS 440A Round Rods spans across sectors where component life cycle, edge retention, and dimensional accuracy are crucial. In the medical and surgical equipment industry, SS 440A is often employed to fabricate blades, scalpels, and other instruments that demand fine edges and corrosion resistance under sterilized conditions. In tool and die manufacturing, the material is a preferred choice for cutting dies, punches, and precision tooling, thanks to its hardness and ability to maintain tolerance under repetitive stress.

In the automotive, aerospace, and mechanical engineering sectors, SS 440A plays a critical role in the production of heavy-duty fasteners, drive shafts, and moving parts within engines and transmissions. Its performance in high-friction environments makes it especially valuable for parts that are subject to sliding contact and intermittent impact. In industrial processing plants, SS 440A rods are used in valve internals, pump components, and fluid control systems, particularly in environments where moderate corrosion resistance is acceptable, but high strength and durability are non-negotiable.

To meet the rising demand across global industrial hubs, our distribution of SS 440A Round Rods covers India, the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq. These regions are witnessing significant growth in manufacturing, infrastructure, oil and gas, and mechanical engineering sectors, all of which require reliable supply of durable stainless steel components. Our inventory includes a wide range of dimensions and finishes, and we also cater to custom requirements, ensuring consistent quality, timely delivery, and full compliance with international standards such as ASTM, ASME, and DIN. Through a deep understanding of regional industrial needs and technical specifications, we deliver solutions tailored to ensure long-term operational efficiency.

| STANDARD | UNS | WNR. |

|---|---|---|

| SS 440A | S44002 | 1.4109 |

SS 440A Square Bar

SS 440A Square Bar, UNS S44002 Square Bar, DIN 1.4109 Square Rod, ASME SA 276 SS 440A Square Bar, Stainless Steel 440A Polish Square Bar, SS 440A Square Rod

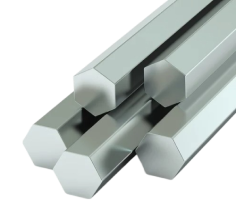

SS 440A Hex Bar

ASME SA276 SS 440A Hex Bar, ASTM A276 Stainless Steel 440A Hex Bar, DIN 1.4109 Hex Bar, UNS S44002 Hex Bar, SS 440A Hex Rod, SS 440A Polish Hex Bar, SS 440A Hex Rod

SS 440A Rectangular Bar

SS ASTM A276 440A Rectangular Bar, UNS S44002 / DIN 1.4109 Rectangular Bar, ASME SA276 SS 440A Rectangular Rod, SS 440A Rectangle Rod, Stainless 440A Rectangle Bar, Polish SS 440A Rectangular Bar Supplier

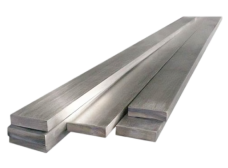

SS 440A Flat Bar

DIN 1.4109 Flat Bar, UNS S44002 Flat Bar, ASME SA 276 Stainless Steel 440A Flat Bar, ASTM A276 440A SS Flat Rod, SS 440A Polish Flat Bar

SS 440A Bright Bar

ASTM A276 440A SS Bright Bar, SS UNS S44002 Bright Bar, SS 440A Bright Rod, SS 440A Polish Bright Bar

SS 440A Forged Bar

UNS S44002 Forged Bar, Stainless Steel 440A Forged Rod, ASTM A276 440A Stainless Steel Polish Forged Bar, ASME SA 276 SS 440A Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 440A Round Bar

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 440A | 0.6 - 0.75 | 1.00 max | 1.00 max | 0.04 max | 0.030 max | 16.00 - 18.00 | - |

Mechanical Properties Of Stainless Steel 440A Round Bar

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Rockwell (HR C) | Impact Charpy V (J) |

|---|---|---|---|---|---|

| Annealed* | 758 | 448 | 14 | 269HB max | - |

| 204 | 2030 | 1900 | 4 | 59 | 9 |

| 260 | 1960 | 1830 | 4 | 57 | 9 |

| 316 | 1860 | 1740 | 4 | 56 | 9 |

| 371 | 1790 | 1660 | 4 | 56 | 9 |

| * Annealed properties are typical for Condition A of ASTM A276# Brinell Hardness is ASTM A276 specified maximum for annealed 440A, B and C. | |||||

Physical Properties of 304/304L/304H Stainless Steel Round Bar

Our SS 440A Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry