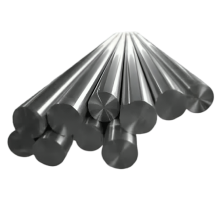

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 347 Round Bars are specialized austenitic stainless steel products designed for high-temperature structural applications. Both grades are stabilized with columbium (niobium), which imparts superior resistance to intergranular corrosion—particularly after welding or prolonged exposure to elevated temperatures in the range of 427°C to 899°C. SS 347 offers excellent creep strength and oxidation resistance, while SS 347H is a high-carbon version specifically engineered to enhance high-temperature creep properties and tensile strength. The increased carbon content in 347H (typically around 0.04–0.10%) makes it ideal for environments where repeated thermal cycling and sustained load-bearing at high temperatures are critical.

Metallurgically, both 347 and 347H contain chromium (17–20%) and nickel (9–13%) as primary alloying elements, contributing to their excellent corrosion resistance and mechanical stability. The addition of niobium effectively prevents chromium carbide precipitation along grain boundaries, which often leads to corrosion in less stabilized grades. These bars and rods maintain excellent weldability and formability, and can be readily fabricated using standard industrial techniques without sacrificing structural integrity. Furthermore, they offer good resistance to polythionic acid stress corrosion cracking, often encountered in refining and chemical processing environments.

From a physical standpoint, SS 347/347H bars retain their dimensional accuracy under thermal stress and exhibit reliable performance in both oxidizing and mildly reducing environments. In their annealed state, these bars exhibit minimal magnetic response and low magnetic permeability, making them ideal for use in environments where electromagnetic interference must be minimized. Overall, these round bars and rods are a high-performance choice for applications where thermal resilience, mechanical strength, and corrosion resistance converge.

Applications

SS 347 and SS 347H round bars and rods are widely utilized in environments where long-term resistance to heat and corrosive media is essential. In high-temperature service conditions, they are employed in components such as heat exchangers, radiant tubes, superheaters, and boiler enclosures. The material’s ability to resist intergranular attack makes it especially suitable for welded constructions in high-pressure environments. Due to its stable microstructure under thermal stress, SS 347 is a preferred material in aircraft exhaust manifolds, chemical process vessels, and expansion joints.

In the petrochemical and refining industries, SS 347H bars and rods are often used in catalytic recovery systems, reforming units, and reactor internals. These applications demand not only resistance to sulfur-bearing atmospheres but also structural integrity under elevated operating pressures and temperatures. The enhanced creep resistance of 347H makes it particularly valuable in steam piping and reheater tubes where dimensional stability over time is non-negotiable.

Additionally, 347/347H stainless steel finds a place in food processing and pharmaceutical equipment, where cleanliness, corrosion resistance, and temperature tolerance must work in tandem. It is also used in cryogenic structures and components subjected to wide temperature swings, owing to its stable mechanical properties at both sub-zero and high heat ranges. Whether for thermal insulation systems, pressure vessels, or high-temperature gaskets, these round bars deliver durability, machinability, and performance without compromise.

Industry Use

The robust characteristics of SS 347 and SS 347H round bars and rods cater to a broad spectrum of industries across high-demand sectors. In chemical processing plants, particularly in India, the Kingdom of Saudi Arabia (KSA), Kuwait, and Qatar, these materials are indispensable for constructing reactors, towers, and pipelines that endure hot acidic or caustic fluids. Their resistance to sensitization and corrosion under thermal stress ensures safe and uninterrupted operation even under the most aggressive chemical exposures.

In power generation and thermal energy plants, SS 347H is commonly found in steam systems, pressure lines, and turbine components, where continuous thermal cycling poses significant challenges. Industrial furnace manufacturers and metallurgical processing units in the Sultanate of Oman and India leverage the high-temperature capabilities of these bars for internal supports, rails, and load-bearing structures exposed to combustion gases and oxidizing atmospheres. Their long service life and low maintenance requirements contribute to reduced operational downtime and improved energy efficiency.

The aerospace and defense sectors also benefit from the performance attributes of SS 347 bars, particularly in engine components, jet exhaust parts, and support frames that must remain dimensionally stable under extreme thermal conditions. In desalination plants and offshore facilities, their chloride resistance adds another layer of reliability in salty, corrosive environments where lesser alloys fail prematurely. With consistent supply across major regions such as India, the Kingdom of Saudi Arabia, Kuwait, Qatar, and Oman, these SS 347 round bars are readily accessible to industries seeking high-performance materials that align with global quality standards and regional operational demands.

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| SS 347 | S34700 | 1.4550 | SUS 347 | X6CrNiNb18-10 |

| SS 347H | S34709 | 1.4961 | SUS 347H | X6CrNiNb18-12 |

SS 347/347H Square Bar

Stainless Steel 347 Square Bar, UNS S34700 / S34709 Square Bar, DIN 1.4550 Square Rod, ASME SA 276 SS 347H Square Bar, Stainless Steel 347 Polish Square Bar, SS 347/347H Square Rod

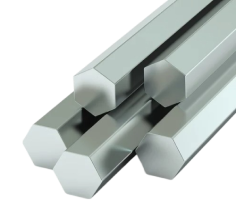

SS 347/347H Hex Bar

ASME SA276 SS 347 / 347H Hex Bar, ASTM A276 Stainless Steel 347 Hex Bar, DIN 1.4961 Hex Bar, UNS S34700 Hex Bar, SS 347 / 347H Hex Rod, SS 347 Polish Hex Bar, SS 347/347H Hex Rod

SS 347/347H Rectangular Bar

Stainless Steel ASTM A276 347 Rectangular Bar, UNS S34700 / DIN 1.4550 Rectangular Bar, ASME SA276 SS 347H Rectangular Rod, SS 347 Rectangle Rod, Stainless 347 Rectangle Bar, Polish SS 347H Rectangular Bar Supplier

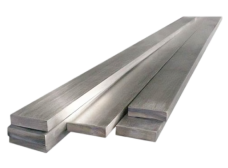

SS 347/347H Flat Bar

DIN 1.4961 Flat Bar, UNS S34700 Flat Bar, ASME SA 276 Stainless Steel 347 Flat Bar, ASTM A276 347H SS Flat Rod, SS 347/347H Polish Flat Bar

SS 347/347H Bright Bar

ASTM A276 347H Stainless Steel Bright Bar, SS UNS S34700/ S34709 Bright Bar, SS 347 Bright Rod, SS 347/347H Polish Bright Bar

SS 347/347H Forged Bar

UNS S34700 Forged Bar, Stainless Steel 347 Forged Rod, ASTM A276 347 Stainless Steel Polish Forged Bar, ASME SA 276 SS 347H Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 347/347H Round Bar

| C | Cr | Mn | Ni | P | S | Si | Cb/Ta | |

|---|---|---|---|---|---|---|---|---|

| 347 | 0.08 max | min: 17.0 max: 20.0 |

2.0 max | min: 9.0 max: 13.0 |

0.04 max | 0.30 max |

0.75 max |

min:10x C max: 1.0 |

| 347H | min: 0.04 max: 0.10 |

min: 17.0 max: 20.0 |

2.0 max | min: 9.0 max: 13.0 |

0.03 max | 0.30 max |

0.75 max |

min:10x C max: 1.0 |

Mechanical Properties Of Stainless Steel 347/347H Round Bar

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% ksi offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 347/347H | 75 (515) |

30 (205) |

40 | 201 | 95 |

Physical Properties of 347/347H Stainless Steel Round Bar

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)-°F |

Thermal Conductivity BTU/hr-ft-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)2-psi | |

|---|---|---|---|---|---|

| at 68 °F | at 68 – 212°F | at 68 – 1832°F | at 200°F | at 32 – 212°F | in tension (E) |

| 0.286 | 9.2 | 20.5 | 9.3 | 0.12 | 28 x 106 |

Our SS 347 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry