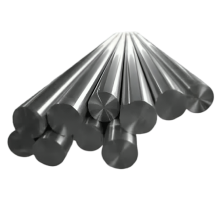

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 431 Round Bars are high-strength, corrosion-resistant stainless steel products engineered from martensitic stainless steel alloy Grade 431. This alloy is primarily composed of iron, chromium (approximately 15-17%), and nickel (1.25-2.50%), with controlled carbon content that allows it to be heat-treated for enhanced mechanical strength and toughness. What sets SS 431 apart is its excellent combination of tensile strength, hardness, and moderate corrosion resistance, making it superior to many conventional martensitic grades in demanding mechanical applications.

The round bars and rods made from SS 431 are manufactured through precision hot or cold rolling processes, followed by heat treatment procedures such as hardening and tempering to achieve desired strength levels. These products exhibit high yield strength, good impact resistance, and excellent resistance to stress and fatigue, especially in high-load mechanical environments. Furthermore, the alloy's ability to retain strength at moderately elevated temperatures makes it well-suited for environments involving mild thermal fluctuations.

Dimensional accuracy, surface finish, and machinability are key characteristics that distinguish SS 431 Round Bars and Rods. While it does have reduced weldability compared to austenitic grades, it can be welded under controlled conditions with proper post-weld heat treatment. The material is magnetic in both annealed and hardened states and displays excellent resistance to scaling and oxidation under atmospheric and mildly corrosive industrial environments. Supplied in both metric and imperial sizes, these bars and rods are available in various finishes such as black, bright, rough turned, and polished, catering to diverse technical requirements across multiple sectors.

Applications of SS 431 Round Bars and Rods

431 Stainless Steel Round Bars are engineered for performance and durability in highly demanding environments. Their primary application lies in the manufacturing of components that are subject to high torque, impact, and wear. These include drive shafts, pump shafts, valve parts, spindles, fasteners, and marine hardware. The alloy’s high tensile and yield strength, combined with good corrosion resistance, makes it ideal for applications where both structural integrity and longevity are paramount.

In marine environments, SS 431 is particularly valued for its resistance to saltwater corrosion and mechanical fatigue, making it suitable for components such as propeller shafts, boat fittings, and offshore drilling hardware. In the aerospace sector, the material is frequently used in the production of landing gear components, actuators, and structural fittings, thanks to its robustness under dynamic loads. Additionally, the automotive and defense industries rely on SS 431 Round Bars for manufacturing parts that require a high strength-to-weight ratio and resistance to stress-induced corrosion.

SS 431 is frequently utilized in demanding rotating equipment and hydraulic assemblies—such as cylinders, pistons, and tooling components—thanks to its excellent hardenability and ability to maintain strength under stress. The rods can also be precisely machined into customized components for industrial automation systems, oil & gas extraction tools, and food-grade processing equipment where hygiene and mechanical performance must coexist. Combining robust mechanical properties with moderate corrosion resistance, SS 431 is a dependable material for a wide range of high-precision engineering applications.

Industry Use and Supply Regions

SS 431 Round Bars/Rods are extensively utilized across a broad spectrum of industries due to their high mechanical performance and moderate corrosion resistance. In the oil and gas sector, these rods are used in the fabrication of drilling tools, offshore platforms, and pipeline components where both strength and resistance to harsh chemicals are critical. In the petrochemical industry, SS 431 is chosen for components exposed to high-pressure steam and mildly corrosive fluids, such as compressor parts and processing valves.

The defense and aerospace industries leverage the material’s strength and fatigue resistance for fabricating parts that operate under continuous stress cycles. Meanwhile, in the power generation and heavy engineering sectors, SS 431 Round Bars/Rods serve as structural support elements, drive shafts, and critical rotating components in turbines and gear systems. The construction and infrastructure sectors utilize these bars for reinforcement in critical load-bearing structures and corrosion-resistant railings or support rods. Moreover, food and beverage processing plants employ SS 431 where a combination of strength, hygiene, and corrosion resistance is essential.

Our supply network for SS 431 Round Rods is strategically focused across major industrial regions, including India, the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq. These markets have a high demand for robust, high-performance stainless steel products, and our ability to meet exacting technical specifications ensures timely delivery and consistent quality. Whether the requirement is for standard sizes or custom-cut lengths, we support engineering, procurement, and manufacturing teams across these regions with technically sound solutions tailored to their specific industrial environments.

| STANDARD | UNS | WNR. | JIS |

|---|---|---|---|

| SS 431 | S43100 | 1.4057 | SUS 431 |

SS 431 Square Bar

Stainless Steel 431 Square Bar, UNS S43100 Square Bar, DIN 1.4057 Square Rod, ASME SA 276 SS 431 Square Bar, Stainless Steel 431 Polish Square Bar, SS 431 Square Rod

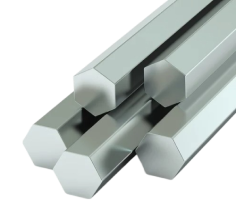

SS 431 Hex Bar

ASME SA276 SS 431 Hex Bar, ASTM A276 Stainless Steel 431 Hex Bar, DIN 1.4057 Hex Bar, UNS S43100 Hex Bar, SS 431 Hex Rod, SS 431 Polish Hex Bar, SS 431 Hex Rod

SS 431 Rectangular Bar

Stainless Steel ASTM A276 431 Rectangular Bar, UNS S43100 / DIN 1.4057 Rectangular Bar, ASME SA276 SS 431 Rectangular Rod, SS 431 Rectangle Rod, Stainless 431 Rectangle Bar, Polish SS 431 Rectangular Bar Supplier

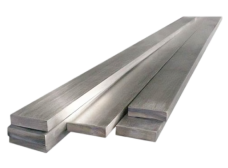

SS 431 Flat Bar

DIN 1.4057 Flat Bar, UNS S43100 Flat Bar, ASME SA 276 Stainless Steel 431 Flat Bar, ASTM A276 431 SS Flat Rod, SS 431 Polish Flat Bar

SS 431 Bright Bar

ASTM A276 431 Stainless Steel Bright Bar, SS UNS S43100 Bright Bar, SS 431 Bright Rod, SS 431 Polish Bright Bar

SS 431 Forged Bar

UNS S43100 Forged Bar, Stainless Steel 431 Forged RUNS S43100 Forged Bar, Stainless Steel 431 Forged Rod, ASTM A276 431 Stainless Steel Polish Forged Bar, ASME SA 276 SS 431 Forged Barod, ASTM A276 431 Stainless Steel Polish Forged Bar, ASME SA 276 SS 431 Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 431 Round Bar

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 431 | 0.20 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 15.00 - 17.00 | 1.25 - 2.50 |

Mechanical Properties Of Stainless Steel 431 Round Bar

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Brinell (HB) | Impact Charpy V (J) |

|---|---|---|---|---|---|

| Annealed * | 862 | 655 | 20 | 285 max | - |

| 204 | 1345 | 1055 | 20 | 388 | 50 |

| 316 | 1295 | 1035 | 19 | 375 | 53 |

| 427 | 1350 | 1080 | 19 | 388 | # |

| 538 | 1140 | 965 | 19 | 321 | # |

| 593 | 1015 | 770 | 20 | 293 | 64 |

| 650 | 960 | 695 | 20 | 277 | 84 |

Physical Properties of 304/304L/304H Stainless Steel Round Bar

Our SS 431 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry