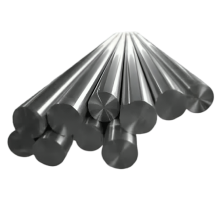

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

321 Round Bars are titanium-stabilized austenitic stainless steel alloys, specifically engineered to provide exceptional resistance to intergranular corrosion following exposure to high temperatures. The primary distinction between the two grades lies in their carbon content—321H contains a higher level of carbon (typically above 0.04%) to enhance creep resistance and elevated temperature strength. These alloys are ideal for applications requiring sustained exposure to temperatures ranging from 800°F to 1500°F (427°C to 816°C), where standard chromium-nickel grades like 304 may become susceptible to sensitization and scaling.

Manufactured in compliance with global standards such as ASTM A276, A479, and ASME SA276, 321 stainless steel round bars and rods offer excellent mechanical properties. They maintain robust tensile strength, ductility, and weldability while exhibiting good resistance to oxidation and stress corrosion cracking. With a balanced composition of chromium (17–19%), nickel (9–12%), and trace amounts of titanium, these bars exhibit superior structural integrity even after prolonged thermal cycling. They are available in various finishes - including black, bright, rough turned, and polished - and can be supplied in diameters ranging from 6 mm to 300 mm or customized based on application needs.

Each batch is subjected to rigorous quality control processes, including ultrasonic testing, hardness testing, and mechanical property verification, ensuring consistent performance under demanding conditions. These technical attributes make 321/321H Round Bars and Rods an optimal choice for industries operating under extreme thermal environments. Our supply capabilities cover a wide geographic footprint, with timely distribution across India, the United Arab Emirates (UAE), the Sultanate of Oman, Iran, and Iraq, meeting the metallurgical needs of both large-scale manufacturers and infrastructure projects.

321/321H Round Bars and Rods are engineered to perform exceptionally in environments where both high temperature and corrosion resistance are critical. Their primary advantage lies in their stability against carbide precipitation, which allows them to retain strength and corrosion resistance even after exposure to heat treatment and welding processes. As a result, they are frequently used in thermal expansion joints, furnace parts, and exhaust manifolds in the automotive and petrochemical industries. Their resistance to scaling and oxidation at elevated temperatures also makes them ideal for high-efficiency heat exchangers, recuperators, and superheaters.

In chemical processing plants, these round bars are employed in reactor vessels, piping systems, and manifolds that handle acidic and oxidizing environments. The enhanced mechanical properties of 321H, in particular, allow it to withstand higher pressures and thermal stresses, making it the preferred variant for more demanding applications. Additionally, these materials are suitable for cryogenic applications where structural stability at low temperatures is equally important. Their excellent weldability also simplifies the fabrication of complex assemblies such as pressure vessels and tanks.

These stainless steel rods and bars are commonly cut, machined, and fabricated into shafts, fasteners, support rods, and structural components that must maintain dimensional integrity during thermal expansion or contraction. Their versatility allows them to be adapted across various operating conditions—ranging from mildly corrosive to moderately oxidizing environments—without compromising performance or longevity. Whether used in static structures or dynamic mechanical systems, 321/321H Round Bars deliver reliable, maintenance-free operation with minimal material degradation over time.

Industry Use and Regional Supply Expertise

321/321H Round Bars and Rods serve as a critical material solution across a wide array of industries where exceptional heat resistance and uncompromising structural integrity are fundamental to performance and longevity. In the aerospace sector, these materials are used in engine components, jet exhaust systems, and thermal shielding applications, where their resistance to oxidation and creep at high temperatures is vital. In the power generation industry, 321H round rods are integrated into boiler tubes, steam headers, and turbine components, ensuring continuous performance under intense thermal cycling. The oil and gas sector leverages these alloys for refining equipment, flare stacks, and pipeline infrastructure that must resist corrosion from hydrocarbons and sulfur compounds.

In pharmaceutical and food processing plants, the cleanability, corrosion resistance, and non-reactive nature of 321 stainless steel make it a trusted material for machinery, piping systems, and contact surfaces. Automotive and transportation manufacturers employ 321 round bars in catalytic converter supports, mufflers, and engine heat shields due to their resilience against thermal shock and vibrational fatigue. These round rods also play a crucial role in the marine industry, especially in shipbuilding and offshore platforms, where resistance to salt spray and high humidity environments is essential for structural integrity.

With an expansive distribution network and proven expertise in supply chain logistics, we ensure the timely and seamless availability of 321/321H Round Bars and Rods across India, the United Arab Emirates (UAE), the Sultanate of Oman, Iran, and Iraq. Our material solutions are tailored to meet project-specific standards, whether for custom specifications or high-volume procurement. Our technical support team collaborates closely with engineers, EPC contractors, and procurement specialists to deliver performance-driven products that align with global industrial standards. Through a combination of regional reach and technical precision, we empower industries to build and maintain systems that thrive under pressure—literally and figuratively.

321/321H Stainless Steel Round Bar Equivalent Grades

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| SS 321 | S32100 | 1.4541 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | S32109 | 1.4878 | SUS 321H | X12CrNiTi18-9 |

SS 321/321H Square Bar

Stainless Steel 321 Square Bar, UNS S32100 / S32109 Square Bar, DIN 1.4541 Square Rod, ASME SA 276 SS 321H Square Bar, Stainless Steel 321 Polish Square Bar, SS 321/321H Square Rod

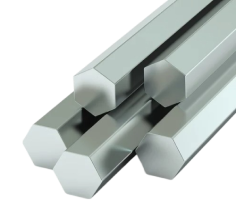

SS 321/321H Hex Bar

ASME SA276 SS 321 / 321H Hex Bar, ASTM A276 Stainless Steel 321 Hex Bar, DIN 1.4878 Hex Bar, UNS S32100 Hex Bar, SS 321 / 321H Hex Rod, SS 321 Polish Hex Bar, SS 321/321H Hex Rod

SS 321/321H Rectangular Bar

Stainless Steel ASTM A276 321 Rectangular Bar, UNS S32100 / DIN 1.4541 Rectangular Bar, ASME SA276 SS 321H Rectangular Rod, SS 321 Rectangle Rod, Stainless 321 Rectangle Bar, Polish SS 321H Rectangular Bar Supplier

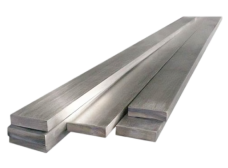

SS 321/321H Flat Bar

DIN 1.4878 Flat Bar, UNS S32100 Flat Bar, ASME SA 276 Stainless Steel 321 Flat Bar, ASTM A276 321H SS Flat Rod, SS 321/321H Polish Flat Bar

SS 321/321H Bright Bar

ASTM A276 321H Stainless Steel Bright Bar, SS UNS S32100/ S32109 Bright Bar, SS 321 Bright Rod, SS 321/321H Polish Bright Bar

SS 321/321H Forged Bar

UNS S32100 Forged Bar, Stainless Steel 321 Forged Rod, ASTM A276 321 Stainless Steel Polish Forged Bar, ASME SA 276 SS 321H Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 321/321H Round Bar

| % | Cr | Ni | C | Si | Mn | P | S | N | Ti | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 321 | min:17.0 max:19.0 |

min: 9.0 max:12.0 |

max:0.08 | max:0.75 | max:2.0 | max:0.045 | max:0.03 | max:0.10 | min:5*(C+N) max:0.70 |

Balance |

| 321H | min:17.0 max:19.0 |

min: 9.0 max:12.0 |

min:0.04 max:0.10 |

min:18.0 max:20.0 |

max:2.0 | max:0.045 | max:0.03 | max:0.10 | min:5*(C+N) max:0.70 |

Balance |

Mechanical Properties Of Stainless Steel 321/321H Round Bar

| Grade | Tensile Strength ksi (min.) |

Yield Strength 0.2% Offset ksi (min.) |

Elongation - % in 50 mm (min.) |

Hardness (Brinell) MAX |

|---|---|---|---|---|

| 321/321H | 75 | 30 | 40 | 217 |

Physical Properties of 321/321H Stainless Steel Round Bar

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)-°F |

Thermal Conductivity BTU/hr-ft-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)2-psi | |

|---|---|---|---|---|---|

| at 68 °F | at 68 – 212°F | at 68 – 1832°F | at 200°F | at 32 – 212°F | in tension (E) |

| 0.286 | 9.2 | 20.5 | 9.3 | 0.12 | 28 x 106 |

Our 321 Round Bar are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry