Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Length :

1 To 6 Meters, Custom Cut Length

Thickness :

50 mm to 6000 mm Long

Size :

14mm-300mm

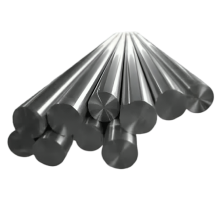

Stainless Steel 317 Round Bars and Rods are advanced austenitic alloys specifically developed to offer superior corrosion resistance when exposed to highly corrosive chemical settings. These grades are an upgraded version of 316/316L, with increased molybdenum content—typically in the range of 3–4%—which provides superior resistance to pitting, crevice corrosion, and general oxidation, particularly in acidic and chloride-rich atmospheres. The primary difference between SS 317 and SS 317L is their carbon content—SS 317 has a higher carbon level, which enhances its strength at elevated temperatures, while SS 317L, with its lower carbon composition, provides improved weldability and minimizes the chance of carbide formation during welding.

These stainless steel round bars and rods are manufactured through hot rolling, cold drawing, or centerless grinding processes, followed by heat treatment and finishing as per application requirements. They are available in a variety of conditions including annealed, pickled, and polished, ensuring high dimensional accuracy, excellent surface finish, and mechanical stability. Both grades exhibit high tensile and yield strength, combined with exceptional ductility and toughness, making them suitable for critical applications under varying pressure and temperature ranges. They are non-magnetic in the annealed condition and remain stable during welding, forming, and machining processes.

Metallurgically, SS 317L possess a robust microstructure that ensures durability in environments containing sulfuric acid, acetic acid, and phosphoric acid, making them ideal for chemical processing applications. The reduced carbon levels in these grades—particularly in 317L—help prevent intergranular corrosion, making them highly effective for use in welded structures without requiring post-weld heat treatment. The presence of molybdenum and higher nickel levels further enhances resistance to atmospheric and chemical corrosion, ensuring long-term service life even in the most challenging industrial environments.

Applications

317 and 317L Stainless Steel Round Bars and Rods are widely utilized in environments where conventional stainless steel grades are prone to failure due to corrosion, especially in chemical and process-intensive industries. One of the most prominent uses of these grades is in the chemical and petrochemical sectors, where they are fabricated into components such as heat exchanger tubes, evaporators, pressure vessels, and scrubbers. Their ability to resist a broad range of acidic compounds makes them particularly effective in the production and handling of aggressive chemicals.

In the pulp and paper industry, SS 317L is favored for digesters, bleach washers, and liquor tanks, where the presence of corrosive chemicals demands a robust, non-degrading material. The food and beverage industry also benefits from the hygienic, non-reactive surface of these stainless steels, making them suitable for mixing vessels, piping systems, and transport containers exposed to salt, acidic ingredients, and steam. Their resistance to organic and inorganic acids helps maintain product purity and equipment longevity.

The low carbon composition of SS 317L makes it especially suitable for welded assemblies, including frameworks, structural reinforcements, and piping systems commonly used in water treatment plants and pharmaceutical operations. These rods are also machined into high-performance fasteners, shafts, and valve bodies in equipment that faces continuous fluid flow, high pressure, or elevated temperatures. From flanges and bolts to instrumentation fittings and custom machined parts, SS 317/317L delivers superior performance where strength and corrosion resistance must coexist.

Industry Use and Supply Reach

Stainless Steel 317 Round Bars and Rods serve as critical components across industries that demand a combination of mechanical strength, high corrosion resistance, and consistent performance under chemical stress. In the oil and gas industry, these grades are employed in offshore platforms, subsea piping, and acid gas handling systems due to their resistance to chloride stress corrosion cracking and sour gas exposure. In marine environments, they are used in pump shafts, seawater piping, and mooring systems where saline exposure demands long-term resistance to corrosion and pitting.

The power generation industry, particularly nuclear and thermal plants, incorporates for boiler components, heat recovery systems, and superheaters, where exposure to high temperatures and corrosive flue gases is common. The mining and metallurgical sectors also utilize these rods in processing tanks and ore handling systems that involve acidic slurries or high abrasion. Even the construction and infrastructure industries turn to these stainless steel grades for architectural supports and outdoor fixtures that must endure both mechanical loads and environmental corrosion.

To support diverse industry requirements across the globe, our supply chain is structured to provide timely and efficient delivery of SS 317/317L Round Bars and Rods in key regions including India, the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq. We offer these bars in a variety of diameters, lengths, and custom finishes to meet project-specific needs, ensuring conformity with international standards such as ASTM A276 and ASTM A479. Our commitment to quality, combined with deep knowledge of regional industry applications, positions us as a reliable partner for procurement teams, fabricators, and EPC contractors across critical sectors.

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| SS 317 | S31700 | 1.4449 | SUS 317 | - |

| SS 317L | S31703 | 1.4438 | SUS 317L | X2CrNiMo18-15-4 |

SS 317/317L Square Bar

SS 317 Square Bar, UNS S31700 / S31703 Square Bar, DIN 1.4449 Square Rod, ASME SA 276 SS 317L Square Bar, Stainless Steel 317 Polish Square Bar, SS 317/317L Square Rod

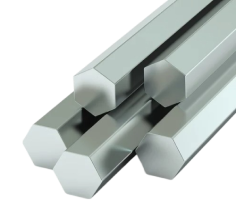

SS 317/317L Hex Bar

ASME SA276 SS 317 / 317L Hex Bar, ASTM A276 Stainless Steel 317 Hex Bar, DIN 1.4438 Hex Bar, UNS S31700 Hex Bar, SS 317 / 317L Hex Rod, SS 317 Polish Hex Bar, SS 317/317L Hex Rod

SS 317/317L Rectangular Bar

SS ASTM A276 317 Rectangular Bar, UNS S31700 / DIN 1.4449 Rectangular Bar, ASME SA276 SS 317L Rectangular Rod, SS 317 Rectangle Rod, Stainless 317 Rectangle Bar, Polish SS 317L Rectangular Bar Supplier

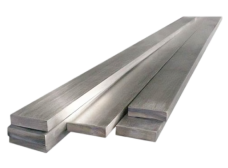

SS 317/317L Flat Bar

DIN 1.4438 Flat Bar, UNS S31700 Flat Bar, ASME SA 276 Stainless Steel 317 Flat Bar, ASTM A276 317L SS Flat Rod, SS 317/317L Polish Flat Bar

SS 317/317L Bright Bar

ASTM A276 317L SS Bright Bar, SS UNS S31700/ S31703 Bright Bar, SS 317 Bright Rod, SS 317/317L Polish Bright Bar

SS 317/317L Forged Bar

UNS S31700 Forged Bar, SS 317 Forged Rod, ASTM A276 317 Stainless Steel Polish Forged Bar, ASME SA 276 SS 317L Forged Bar

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Length :

1 To 6 Meters, Custom Cut Length

Thickness :

50 mm to 6000 mm Long

Size :

14mm-300mm

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Chemical Composition of SS 317/317L Round Bar

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| 317 | 0.08 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 14 | - |

| 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 – 20 | 3 – 4 | 11 – 15 | - |

Mechanical Properties Of Stainless Steel 317/317L Round Bar

| Density | 8.0 g/cm3 |

|---|---|

| Melting Point | 1454 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

Physical Properties of 317/317L Stainless Steel Round Bar

|

Physical Properties (Room Temperature) |

||

|---|---|---|

|

Specific Heat (0-100°C) |

500 |

J.kg-1.°K-1 |

|

Thermal Conductivity |

14.6 |

W.m -1.°K-1 |

|

Thermal Expansion |

16.5 |

mm/m/°C |

|

Modulus Elasticity |

193 |

GPa |

|

Electrical Resistivity |

7.4 |

μohm/cm |

|

Density |

7.99 |

g/cm3 |

Our Stainless Steel 317 Round Bar are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry