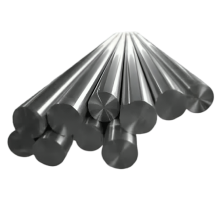

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 309 Round Bars are premium-grade austenitic stainless steel products engineered for superior performance in high-temperature environments. These grades are composed primarily of chromium (22–26%) and nickel (12–22%), which significantly enhance their resistance to oxidation, scaling, and corrosion, even under continuous exposure to elevated temperatures. SS 309 offers excellent heat resistance up to 980°C, while SS 310 and its low-carbon variant SS 310S are capable of withstanding temperatures exceeding 1100°C in intermittent service and up to 1040°C in continuous operations. The reduced carbon content in SS 310S minimizes the risk of carbide precipitation during welding, making it ideal for applications requiring superior weldability and structural integrity.

These stainless steel round bars and rods are manufactured through advanced hot rolling or cold drawing processes, followed by precise annealing to achieve a consistent grain structure and enhanced mechanical properties. The surface finishes range from black and pickled to bright polished and centerless ground, meeting diverse industrial tolerances and quality standards. SS 309/310/310S rods demonstrate high tensile strength, excellent ductility, and strong resistance to thermal fatigue and creep deformation. The austenitic structure not only provides superior toughness at cryogenic temperatures but also contributes to the material’s good machinability and formability, making it suitable for complex fabrication tasks.

309/310/310S Round Bars and Rods are available in a wide range of diameters, lengths, and tolerances, customizable to meet specific engineering requirements. Their non-magnetic nature in the annealed condition, combined with excellent structural stability, allows these alloys to perform reliably across a wide spectrum of industrial applications. With strict adherence to ASTM, ASME, and international standards, these products are designed to ensure long service life, especially in environments involving thermal cycling, oxidation, or corrosive gases.

Applications of stainless steel 309, 310, 310S Round Bars and Rods

Thanks to their outstanding heat and corrosion resistance, SS 309/310/310S Round Bars and Rods are integral to a wide range of thermal processing and structural applications. These grades are particularly valued in the fabrication of furnace parts, radiant tubes, heat treatment baskets, and tube hangers used in continuous annealing lines and carburizing environments. Their ability to retain mechanical strength at high temperatures makes them ideal for components subjected to thermal stress and heavy wear.

In industrial heating systems, these round bars are widely used to manufacture burners, combustion chambers, and thermowells. Their oxidation resistance makes them suitable for use in flue gas ducts, recuperators, and boiler parts. The food processing industry also relies on these grades for equipment exposed to hot acids and steam, including baking racks, sterilizers, and steam tunnels. The SS 310S variant, with its low carbon content, is especially beneficial for applications that require frequent welding or resistance to sensitization and intergranular corrosion.

Beyond high-temperature operations, SS 310S Round Bars and Rods are also employed in cryogenic components, such as storage tanks and structural supports, where toughness at sub-zero temperatures is critical. Their excellent resistance to sulfidation and hot corrosion allows for reliable use in petrochemical reactors, coal gasifiers, and pulp & paper processing units. The versatility of these grades ensures compatibility with a variety of industrial fluids, chemical agents, and atmospheric conditions, thereby expanding their functional utility across critical operations.

Industry Use and Supply Reach

SS 309/310/310S Round Bars and Rods are essential materials in industries that demand both high-temperature endurance and long-term corrosion resistance. In the petrochemical and oil & gas sectors, these stainless steel rods are widely used in the construction of cracking units, flare stacks, and reformer tubes where exposure to harsh chemical atmospheres and fluctuating heat is constant. In power generation plants, these grades are instrumental in boiler internals, superheater tubes, and exhaust manifolds due to their resistance to oxidation and scaling under prolonged heat exposure.

The metallurgical and thermal processing industries utilize SS 309 and SS 310 series rods in the fabrication of equipment such as heat exchangers, kilns, retorts, and incinerator liners. These industries benefit from the material’s low thermal expansion, high creep strength, and resistance to carburization, which make them ideal for high-duty cycles. Additionally, in aerospace and defense sectors, these round bars serve in engine components and structural assemblies that require dimensional stability and reliability at elevated or fluctuating temperatures.

To ensure timely supply and support growing demand, our distribution network for SS 310 Round Bars and Rods covers major industrial hubs across India, the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq. Our in-depth understanding of regional industry needs, combined with a commitment to stringent quality standards, enables us to deliver consistent and dependable stainless steel solutions for mission-critical operations. Whether for standard stock items or custom-engineered components, we provide reliable and timely supply to meet the evolving needs of manufacturers, EPC contractors, and end-users in these high-growth markets.

309/310/310S Stainless Steel Round Bar Equivalent Grades

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST |

|---|---|---|---|---|---|---|---|

| SS 309 | S30900 | 1.4828 | - | - | SUS 309 | - | - |

| SS 310 | S31000 | 1.4841 / 1.4307 | - | X15CrNi25-20 | SUS 310 | 310S24 | 20Ch25N20S2 |

| SS 310S | S31008 | 1.4845 | - | - | SUS 310S | - | 20Ch23N18 |

SS 309/310/310S Square Bar

Stainless Steel 309 Square Bar, UNS S30900 / S31000 / S31008 Square Bar, DIN 1.4307 Square Rod, ASME SA 276 SS 310S Square Bar, Stainless Steel 309 Polish Square Bar, SS 309/310/310S Square Rod

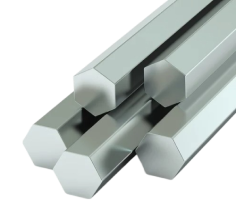

SS 309/310/310S Hex Bar

ASME SA276 SS 310 /310S Hex Bar, ASTM A276 Stainless Steel 309 Hex Bar, DIN 1.4841 / 1.4307 Hex Bar, UNS S31008 Hex Bar, SS 309 / 310 / 310S Hex Rod, SS 309 Polish Hex Bar, SS 309/310/310S Hex Rod

SS 309/310/310S Rectangular Bar

Stainless Steel ASTM A276 309 Rectangular Bar, UNS S30900 / DIN 1.4845 Rectangular Bar, ASME SA276 SS 310 Rectangular Rod, SS 309 Rectangle Rod, Stainless 310S Rectangle Bar, Polish SS 310S Rectangular Bar Supplier

SS 309/310/310S Flat Bar

DIN 1.4828 Flat Bar, UNS S30900 Flat Bar, ASME SA 276 Stainless Steel 310 Flat Bar, ASTM A276 310S SS Flat Rod, SS 309/310/310S Polish Flat Bar

SS 309/310/310S Bright Bar

ASTM A276 310S SS Bright Bar, SS UNS S30900/ S31000/ S31008 Bright Bar, SS 309 Bright Rod, SS 309/310/310S Polish Bright Bar

SS 304/304L/304H Forged Bar

UNS S30400 Forged Bar, SS 304 Forged Rod, ASTM A276 304L Stainless Steel Polish Forged Bar, ASME SA 276 SS 304H Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 309/310/310S Round Bar

| C | Mn | Si | P | S | Cr | Ni | Fe | |

|---|---|---|---|---|---|---|---|---|

| 309 | 0.2 max | 2.0 max | 1.0 max | 0.045max | 0.03max | 22 24 | 12-15 | Balance |

| 310 | 0.25 max | 2.0 max | 1.50 max | 0.045max | 0.03max | 24-26 | min: 8.0 max: 12.0 | Balance |

| 310S | 0.08 max | 2.00 max | 1.50 max | 0.045 | 0.03 | 24-26 | 19-22 | Balance |

Mechanical Properties Of Stainless Steel 309/310/310S Round Bar

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Brinell) MAX |

|---|---|---|---|---|

| 309 | 40 | 30 | 40 | 217 |

| 310 | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40% | - |

| 310S | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40% | - |

Physical Properties of 309/310/310S Stainless Steel Round Bar

| Grade | Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/ °F x 10-6 |

Specific Heat (BTU/lb/ °F) |

Melting Range (°F) |

|---|---|---|---|---|---|---|---|

| 309 | at 68°F: 0.285 | 9.0 at 32- 212°F | 30.7 at 68°F | 28.5 | 8.28 at 32 – 212°F | 0.1200 at 68°F to 212°F | 2500-2590 |

Our SS 309 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry