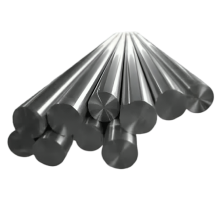

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 410 Round Bars are fabricated from a martensitic stainless steel grade that offers an exceptional combination of mechanical strength, hardness, and moderate corrosion resistance. Comprising primarily of chromium (11.5%–13.5%), this alloy exhibits notable hardenability, making it particularly suitable for heat-treated applications where wear resistance and tensile strength are critical. Unlike austenitic grades, SS 410 does not contain significant nickel, which results in lower ductility but enhanced edge retention and abrasion resistance after tempering. These round bars are magnetic in both annealed and hardened conditions, offering versatility in environments where magnetic responsiveness is a design requirement.

The microstructure of SS 410 can be precisely altered through controlled heat treatments such as annealing, quenching, and tempering, which allows customization of hardness levels based on specific end-use demands. In the annealed state, SS 410 exhibits good machinability and fair corrosion resistance, suitable for mild chemical and atmospheric conditions. However, once hardened, it achieves Rockwell hardness levels up to 50 HRC or higher, making it ideal for load-bearing and wear-intensive environments. The presence of carbon (up to 0.15%) plays a vital role in enhancing strength while maintaining acceptable corrosion resistance, especially in water and air-exposed applications.

Produced in varied diameters and lengths, SS 410 round rods conform to multiple global standards, including ASTM A276 and A479. Precision machining and surface finishing further enhance product reliability, enabling tight tolerances for critical engineering components. Our supply chain capabilities ensure consistent availability of SS 410 round bars with mill test certifications and traceability, delivered efficiently across India, the UAE, Saudi Arabia, Kuwait, Qatar, Oman, Iran, and Iraq. Available in forged, peeled, or ground finishes, these bars are engineered to align with the precise specifications demanded by professionals in advanced engineering and industrial fabrication fields.

Applications

SS 410 Round Bars and Rods are utilized across diverse applications that require a reliable balance of mechanical strength, structural integrity, and resistance to environmental wear. One of the primary uses is in the fabrication of mechanical components such as shafts, spindles, pins, and fasteners that require a fine balance between toughness and machinability. The steel’s response to heat treatment allows engineers to dial in precise performance metrics, making it a reliable choice for custom parts in dynamic systems like pumps, valves, and couplings.

The tooling sector relies on SS 410 for manufacturing precision components such as cutting tools, shaping equipment, and industrial dies due to its hardness and wear resistance. Its ability to retain sharp edges and resist wear under stress makes it highly effective in both manual and automated operations. For the oil and gas sector, SS 410 rods are machined into downhole tools and valve components where temperature variation, exposure to saline environments, and high pressure are common. Its thermal resistance also enables usage in furnace parts and other high-temperature mechanical assemblies.

Marine hardware, turbine blades, automotive linkages, and kitchen equipment are other areas where stainless steel round bar 410 is gaining traction. While not as corrosion-resistant as austenitic grades in highly chlorinated or acidic environments, its durability and cost-effectiveness make it an ideal candidate for inland water applications and moderately corrosive industrial atmospheres. With proper passivation and surface treatments, its lifespan and performance in outdoor or moist environments can be significantly extended.

Industry Use

SS 410 Round Bars and Rods are integral to a variety of industrial sectors that demand robust materials with adaptable mechanical properties. In the automotive and transportation industry, these bars are widely used for the manufacture of drive shafts, gear components, and brackets. Their high strength-to-weight ratio and resistance to mechanical wear ensure long service life even under cyclic loading and impact conditions. Components made from SS 410 are frequently deployed in suspension systems, axle assemblies, and transmission systems.

In the oil, gas, and petrochemical industry, particularly in regions like the Middle East—including Saudi Arabia, the UAE, Kuwait, and Iran—SS 410 bars are a standard choice for components that must endure harsh operational environments. This encompasses components like rig equipment, flow control valves, and pipeline flanges commonly employed in upstream and midstream processes. The material's resilience under fluctuating pressures and its ability to retain structural integrity in high-temperature environments make it essential for exploration and refining equipment.

Manufacturing, construction, and power generation sectors in India and GCC nations also utilize SS 410 round rods in large-scale fabrication projects, including support frames, structural fasteners, and load-bearing beams. In thermal and hydroelectric plants, SS 410 is favored for its thermal fatigue resistance, used in turbines, boiler components, and pump housings. Furthermore, in food processing and industrial kitchenware manufacturing, SS 410 offers hygiene compatibility and ease of sterilization, making it suitable for knife blades, equipment shafts, and processing tools. The steel’s compliance with international quality and safety standards enhances its value in these regulated environments.

Our extensive supply footprint across India, UAE, KSA, Oman, Qatar, Kuwait, Iran, and Iraq enables us to support industrial procurement needs efficiently. With localized warehousing and logistics networks, we ensure timely deliveries and technical support, making SS 410 round bars a dependable solution across a wide industrial spectrum.

| STANDARD | UNS | WNR. | JIS |

|---|---|---|---|

| SS 410 | S41000 | 1.4550 | SUS 410 |

SS 410 Square Bar

Stainless Steel 410 Square Bar, UNS S41000 Square Bar, DIN 1.4006 Square Rod, ASME SA 276 SS 410 Square Bar, Stainless Steel 410 Polish Square Bar, SS 410 Square Rod

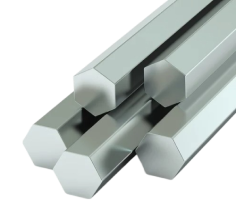

SS 410 Hex Bar

ASME SA276 SS 410 Hex Bar, ASTM A276 SS 410 Hex Bar, DIN 1.4006 Hex Bar, UNS S41000 Hex Bar, SS 410 Hex Rod, SS 410 Polish Hex Bar, SS 410 Hex Rod

SS 410 Rectangular Bar

Stainless Steel ASTM A276 410 Rectangular Bar, UNS S41000 / DIN 1.4006 Rectangular Bar, ASME SA276 SS 410 Rectangular Rod, SS 410 Rectangle Rod, Stainless 410 Rectangle Bar, Polish SS 410 Rectangular Bar Supplier

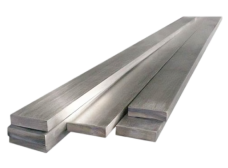

SS 410 Flat Bar

DIN 1.4006 Flat Bar, UNS S41000 Flat Bar, ASME SA 276 SS 410 Flat Bar, ASTM A276 410 SS Flat Rod, SS 410 Polish Flat Bar

SS 410 Bright Bar

ASTM A276 410 Stainless Steel Bright Bar, SS UNS S41000 Bright Bar, SS 410 Bright Rod, SS 410 Polish Bright Bar

SS 410 Forged Bar

UNS S41000 Forged Bar, SS 410 Forged Rod, ASTM A276 410 Stainless Steel Polish Forged Bar, ASME SA 276 SS 410 Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 410 Round Bar

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 410 | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 |

0.50 max |

Mechanical Properties Of Stainless Steel 410 Round Bar

| Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|

| 65 (450) | 30 (205) | 20 | 217 | 96 |

Physical Properties of 410 Stainless Steel Round Bar

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)-°F |

Thermal Conductivity BTU/hr-ft-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)2-psi | |

|---|---|---|---|---|---|

| at 68 °F | at 68 – 212°F | at 68 – 1832°F | at 200°F | at 32 – 212°F | in tension (E) |

| 0.286 | 9.2 | 20.5 | 9.3 | 0.12 | 28 x 106 |

Our SS 410 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry