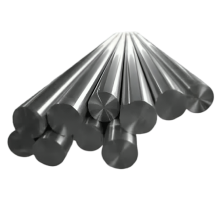

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 420 Round Bars are produced from a martensitic stainless steel alloy that is primarily composed of chromium, typically ranging between 12% to 14%, and contains a higher carbon content than many other stainless grades. This unique composition allows the material to be heat-treated to achieve enhanced hardness and strength. SS 420 is best known for its ability to be hardened through heat treatment, reaching a Rockwell hardness of up to 50 HRC depending on the tempering process. When properly processed, SS 420 exhibits excellent mechanical properties, including high tensile strength, improved wear resistance, and good dimensional stability under load.

This grade is magnetic in all conditions and has moderate corrosion resistance, which improves significantly when the surface is polished or passivated. Though not recommended for aggressive or chloride-heavy environments, SS 420 delivers dependable performance in freshwater settings, mildly corrosive atmospheres, and chemically stable conditions. Its weldability is considered fair and generally requires preheating and post-weld tempering to relieve stress and prevent cracking. The round bar and rod formats are commonly produced through hot rolling or precision grinding, resulting in smooth surfaces, tight tolerances, and optimal machinability. SS 420 round bars are available in a wide range of sizes, finishes, and custom-cut lengths to meet diverse industrial requirements.

In regions like India, the UAE, Saudi Arabia, and other parts of the GCC, the consistent demand for materials that combine high mechanical performance with moderate corrosion resistance has led to the growing use of SS 420. Its adaptability to fabrication, coupled with its ability to maintain hardness and sharpness, makes it a preferred material in precision engineering, especially in applications where durability under mechanical stress is a priority.

Applications of SS 420 Round Bars/Rods

SS 420 round bars and rods serve an extensive range of applications that demand hardness, wear resistance, and mechanical strength. One of the most well-known uses of this grade is in the production of cutting tools, surgical instruments, knives, and industrial blades due to its ability to hold a sharp edge and endure repeated impact. Its high polishability also makes it ideal for manufacturing components that require a smooth, refined finish, such as pump shafts, valve parts, and turbine blades. In automotive and aerospace industries, 420 stainless steel round bars and rods is often used in producing engine parts, fasteners, and structural assemblies exposed to stress and moderate corrosion.

Another major area of application is in mold-making for plastic injection and die-casting industries. The alloy’s hardness and thermal resistance make it suitable for tools and dies that must endure repeated cycles under high temperature and pressure. In marine and freshwater systems, SS 420 round rods are employed in components such as shafts and fasteners, provided they are not exposed to prolonged chloride exposure. Its use in medical devices is also prominent, especially for non-implantable instruments like forceps, scalpels, and dental tools, where hygiene, sharpness, and durability are critical.

In modern infrastructure projects across India, Oman, and Qatar, SS 420 is selected for architectural features that require both aesthetic appeal and resistance to mechanical damage—such as handrails, decorative trims, and customized steelwork. The alloy's surface can be finely polished, enhancing its visual appeal while retaining core structural performance. These bars are also gaining traction in manufacturing environments for conveyor components, mechanical guides, and custom machine parts due to their performance in abrasive conditions and ability to withstand frequent handling and friction.

Industry Use and Regional Supply Demand

The industrial demand for SS 420 round bars and rods continues to rise across various sectors, driven by the need for strong, wear-resistant materials that can perform under stress while offering basic corrosion resistance. In the manufacturing and engineering sectors throughout India and the GCC—including Kuwait, Iran, and Iraq—SS 420 is widely used for fabricating components exposed to repeated mechanical load, impact, or abrasive conditions. Its cost-effectiveness compared to high-end alloys and its reliable performance make it a logical choice for both mass production and specialized manufacturing.

In the oil, gas, and petrochemical industries across KSA, UAE, and Qatar, SS 420 round rods are used for secondary mechanical components such as pump parts, fittings, and mechanical seals that require high strength and wear resistance without constant exposure to highly corrosive agents. In tooling and industrial machining sectors, especially within Oman and Kuwait, manufacturers rely on SS 420 for durable cutting, drilling, and shaping tools that must retain sharpness over long production cycles.

From a supply chain perspective, our strategic sourcing and distribution network ensures a steady and timely supply of SS 420 round bars and rods to customers in India and the Gulf region. Whether required in standard sizes or as customized lengths and finishes, our offerings are tailored to meet diverse industrial needs while adhering to international quality standards. As demand grows for high-performance stainless materials in both legacy and emerging markets, SS 420 stands out for its proven strength, versatility, and adaptability across sectors. Our regional supply capabilities ensure that clients across the Middle East and South Asia receive consistent, application-ready products backed by technical expertise and responsive support.

| STANDARD | UNS | WNR. | JIS |

|---|---|---|---|

| SS 420 | S42000 | 1.4021 | SUS 420 |

SS 420 Square Bar

Stainless Steel 420 Square Bar, UNS S42000 Square Bar, DIN 1.4021 Square Rod, ASME SA 276 SS 420 Square Bar, Stainless Steel 420 Polish Square Bar, SS 420 Square Rod

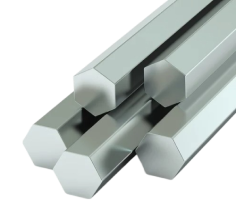

SS 420 Hex Bar

ASME SA276 SS 420 Hex Bar, ASTM A276 Stainless Steel 420 Hex Bar, DIN 1.4021 Hex Bar, UNS S42000 Hex Bar, SS 420 Hex Rod, SS 420 Polish Hex Bar, SS 420 Hex Rod

SS 420 Rectangular Bar

Stainless Steel ASTM A276 420 Rectangular Bar, UNS S42000 / DIN 1.4021 Rectangular Bar, ASME SA276 SS 420 Rectangular Rod, SS 420 Rectangle Rod, Stainless 420 Rectangle Bar, Polish SS 420 Rectangular Bar Supplier

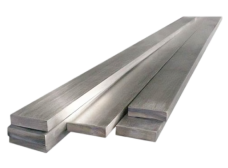

SS 420 Flat Bar

DIN 1.4021 Flat Bar, UNS S42000 Flat Bar, ASME SA 276 Stainless Steel 420 Flat Bar, ASTM A276 420 SS Flat Rod, SS 420 Polish Flat Bar

SS 420 Bright Bar

ASTM A276 420 Stainless Steel Bright Bar, SS UNS S42000 Bright Bar, SS 420 Bright Rod, SS 420 Polish Bright Bar

SS 420 Forged Bar

UNS S42000 Forged Bar, Stainless Steel 420 Forged Rod, ASTM A276 420 Stainless Steel Polish Forged Bar, ASME SA 276 SS 420 Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 420 Round Bar

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 420 | 0.15 max |

1.00 max |

1.00 max |

0.04 max |

0.03 max |

min: 12.0 max: 14.0 |

- |

Mechanical Properties Of Stainless Steel 420 Round Bar

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) |

Elongation (% in 50mm) |

Hardness Brinell (HB) |

|---|---|---|---|---|

| Annealed * | 655 | 345 | 25 | 241 max |

| 399°F (204°C) | 1600 | 1360 | 12 | 444 |

| 600°F (316°C) | 1580 | 1365 | 14 | 444 |

| 800°F (427°C) | 1620 | 1420 | 10 | 461 |

| 1000°F (538°C) | 1305 | 1095 | 15 | 375 |

| 1099°F (593°C) | 1035 | 810 | 18 | 302 |

| 1202°F (650°C) | 895 | 680 | 20 | 262 |

| * Annealed tensile properties are typical for Condition A of ASTM A276; annealed hardness is the specified maximum. | ||||

Our SS 420 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry