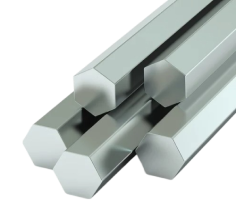

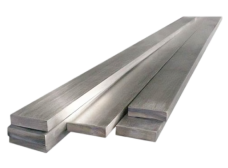

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Length :

1 To 6 Meters, Custom Cut Length

Thickness :

50 mm to 6000 mm Long

Size :

14mm-300mm

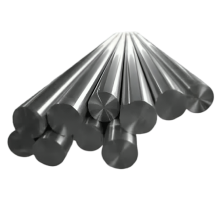

446 Round Bars and Rods are engineered from a high-chromium ferritic stainless steel grade renowned for its exceptional resistance to corrosion, scaling, and oxidation at elevated temperatures. The alloy composition typically includes a chromium content of around 23–27%, which contributes significantly to its superior performance in extreme thermal environments. Unlike austenitic grades, 446 stainless steel exhibits excellent resistance to sulfidation and oxidation, making it an ideal candidate for use in high-temperature industrial settings. Its ferritic microstructure ensures high thermal conductivity and low thermal expansion, which are critical for maintaining dimensional stability under fluctuating thermal loads.

A key advantage of 446 round bars and rods lies in their exceptional resistance to harsh oxidizing environments and stress corrosion caused by chlorides. While not heat-treatable for hardening purposes, these bars can be cold worked to enhance strength and dimensional accuracy. The alloy also maintains decent machinability and formability, despite its relatively higher hardness compared to lower-chromium ferritic steels. Thanks to its low carbon content, 446 stainless steel offers improved weldability without the risk of grain boundary carbide precipitation, ensuring long-term structural integrity in welded assemblies.

Additionally, 446 round bars exhibit magnetic properties typical of ferritic steels and demonstrate stable performance under cyclic heating conditions. The metallurgical balance of the alloy supports resistance to carburization and nitriding, making it well-suited for exposure to combustion gases and industrial furnace atmospheres. These attributes collectively contribute to the alloy’s reputation as a reliable choice for engineering components requiring longevity, dimensional precision, and thermal endurance.

Applications

446 Stainless Steel Round Bars and Rods find extensive use in high-temperature service applications where resistance to oxidation, corrosion, and thermal fatigue is critical. In thermal processing environments, they are frequently used in the fabrication of heat exchangers, boiler components, and radiant tubes. Their robustness under oxidizing and carburizing conditions makes them ideal for furnace parts such as muffle furnaces, retorts, and burner assemblies. These bars are also used in heat shields, baffles, and recuperators where structural performance and oxidation resistance must be maintained over prolonged service intervals.

In the petrochemical and energy sectors, 446 round bars are employed in components exposed to hot sulfur-bearing environments. Their resistance to sulfidation ensures reliable function in environments containing hydrogen sulfide or other corrosive gases. Moreover, these rods are utilized in waste incineration systems and exhaust manifolds where thermal cycling and corrosive byproducts can compromise lesser materials. Their durability significantly reduces maintenance downtime, enhancing operational efficiency in mission-critical systems.

The marine and coastal industries also benefit from 446 bars in select non-load-bearing applications, particularly where chloride exposure is intermittent but elevated temperatures are routine. Additionally, food processing plants leverage the alloy's corrosion resistance in certain drying and roasting units where consistent performance is needed in hot and mildly corrosive environments. This broad utility stems from the alloy’s engineered capacity to endure chemically aggressive, thermally intense, and structurally demanding conditions.

Industry Use

The demand for 446 Round Bars and Rods spans a diverse array of industries that prioritize heat resistance, corrosion protection, and mechanical durability. In the metal processing and thermal treatment sector, these bars are indispensable for manufacturing internal furnace fixtures, supports, and thermal shields that must function reliably at sustained temperatures exceeding 1000°C. Their resistance to deformation under thermal load reduces the frequency of replacements, making them a cost-effective long-term solution for industrial heat treatment lines.

The oil and gas industry, particularly in regions like the Kingdom of Saudi Arabia, Kuwait, and Qatar, extensively uses 446 stainless steel in upstream and midstream operations where components face corrosive gases and extreme temperature fluctuations. Applications such as flare stacks, catalyst support grids, and piping in high-temperature reactors benefit from the alloy’s resilience. Similarly, in chemical and petrochemical facilities across India and Oman, these bars are integrated into processing units where exposure to hot organic acids, chlorides, and sulfur compounds is routine.

Furthermore, energy generation and waste-to-energy plants utilize 446 round rods in combustion zones, where materials must endure ash, acidic condensates, and oxidative stress. Cement plants and glass manufacturing industries also deploy this alloy in kilns, lehr rollers, and transport fixtures due to its thermal stability and resistance to scaling. The alloy’s availability across key supply regions including India, the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, and the Sultanate of Oman ensures that industries operating in harsh climates and demanding infrastructures can reliably source high-quality 446 round bars tailored to their performance needs.

| STANDARD | UNS | WNR. |

|---|---|---|

| SS 446 | S44600 | 1.4762 |

SS 446 Perforated Sheets

SS 446 Perforated Sheets, UNS S44600 Perforated Sheets, DIN 1.4762 Perforated Sheets, ASME SA 240 SS 446 Perforated Sheets, Stainless Steel S44600 Perforated Sheets

SS 446 Chequered Plates

ASME SA240 SS 446 Chequered Plates, ASTM A240 Stainless Steel 446 Chequered Plates, DIN 1.4762 Chequered Plates, UNS S44600 Chequered Plates, SS 446 Checkered Plates

SS 446 Shim Sheets

SS ASTM A240 446 Shim Sheets, UNS S44600 / DIN 1.4762 Shim Sheets, ASME SA240 SS 446 Shim Sheets, SS 446 Shim Sheet, Stainless 446 Shim Sheets, SS 446 Shim Sheets Supplier

SS 446 Coils

DIN 1.4762 Coils, UNS S44600 Coils, ASME SA 240 Stainless Steel 446 Coils, ASTM A240 446 SS Coils

SS 446 Strips

ASTM A240 446 SS Strips, SS UNS S44600 Strips, Stainless Steel 446 Strips, SS 1.4762 Strips

SS 446 Foils

UNS S44600 Foils, SS 446 Foils, ASTM A240 446 Stainless Steel Foils, Stainless Steel 446 Foils

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Length :

1 To 6 Meters, Custom Cut Length

Thickness :

50 mm to 6000 mm Long

Size :

14mm-300mm

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Chemical Composition of Stainless Steel 446 Sheets and Plates

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 446 | 0.20 max | 1.50 max | 0.75 max | 0.040 max | 0.030 max | 23.00 | 0.50 |

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 446 | 0.20 max | 1.50 max | 0.75 max | 0.040 max | 0.030 max | 23.00 | 0.50 |

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 446 | 0.20 max | 1.50 max | 0.75 max | 0.040 max | 0.030 max | 23.00 | 0.50 |

Mechanical Properties Of Stainless Steel 446 Sheets and Plates

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|

| Psi – 75,000 , MPa – 485 | Psi – 40,000 , MPa – 275 | 20 % |

Our 446 Round Bar are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry