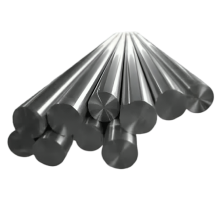

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 17-4PH Round Bars and Rods are high-strength, precipitation-hardening stainless steel products engineered for demanding structural and mechanical environments. Known for their exceptional combination of strength, hardness, and corrosion resistance, these bars are manufactured using a martensitic stainless steel alloy containing approximately 17% chromium and 4% nickel, as well as copper and minor alloying elements that promote precipitation hardening during heat treatment. This composition allows the material to achieve excellent mechanical performance through controlled heat treatment without compromising corrosion resistance—making it particularly well-suited for long-term use in chemically aggressive or high-stress environments.

One of the most significant advantages of SS 17-4PH is its capacity to be heat treated to a variety of conditions (H900, H1025, H1150, etc.), each offering a tailored balance of hardness, tensile strength, and toughness. In the H900 condition, for instance, the material can reach yield strengths in excess of 1000 MPa, while retaining dimensional stability and structural integrity. Its machinability is considered good in the annealed state and remains manageable even after hardening, a critical factor for industries requiring tight tolerances and high-volume production. Weldability is another strength of SS 17-4PH, provided that proper post-weld heat treatments are applied to restore mechanical properties.

SS 17-4PH round bars are produced in a wide range of diameters and surface finishes, including hot-rolled, peeled, ground, and centerless-turned forms. They conform to international quality standards such as ASTM A564 and AMS 5643, ensuring reliability for high-performance engineering. Our supply chain is well-positioned to deliver these bars across India, the United Arab Emirates, the Kingdom of Saudi Arabia, Kuwait, Qatar, Oman, Iran, and Iraq—supported by full traceability, material test certificates, and value-added services like precision cutting and custom heat treatment to meet specific application requirements.

Applications

The high-strength and corrosion-resistant profile of SS 17-4PH Round Bars and Rods makes them a preferred material for a wide array of advanced engineering applications. In the aerospace industry, these bars are extensively used in the manufacturing of structural components, shafts, landing gear assemblies, and fasteners. Their ability to maintain mechanical integrity under cyclic loading, combined with resistance to atmospheric and saltwater corrosion, makes them well-suited for both airframe and engine components. The high fatigue strength of SS 17-4PH is particularly critical in applications involving vibration and stress reversal, ensuring durability and safety over long service lives.

In the manufacturing sector, 17-4PH stainless steel round bars is commonly used to produce dies, injection molds, pump shafts, gears, and high-pressure fittings. Its excellent mechanical properties allow these components to function reliably under extreme pressure and temperature conditions, including those found in hydraulic and pneumatic systems. Additionally, the alloy's good machinability—especially in the H1150 condition—facilitates the production of complex geometries with tight dimensional tolerances. This adaptability allows manufacturers to optimize performance while reducing maintenance intervals and operational costs.

SS 17-4PH is also widely implemented in the food processing, chemical, and pulp & paper industries, where both strength and resistance to process-related corrosion are vital. The material’s stainless nature, combined with its heat-treatable properties, allows for the production of components that resist wear, oxidation, and contamination over prolonged usage cycles. Valves, mixers, shafts, and agitators made from this alloy help maintain hygienic conditions while enduring the rigors of mechanical and chemical stress—an essential requirement for industries governed by strict regulatory standards.

Industry Use

The versatility and performance characteristics of SS 17-4PH Round Bars and Rods make them indispensable across multiple industry verticals in both domestic and international markets. In the aerospace and defense sectors, the alloy’s high tensile strength and corrosion resistance are leveraged in components where weight-to-strength ratio and structural reliability are mission-critical. Aircraft frames, engine mounts, and weapons system parts are just a few of the elements benefiting from the material’s consistent mechanical properties and fatigue resistance.

In the oil, gas, and petrochemical industries, especially in regions such as Saudi Arabia, the UAE, Kuwait, and Iran, SS 17-4PH is used to fabricate pump shafts, flange adaptors, and pressure containment parts. These components often operate in harsh, corrosive environments where temperature fluctuations and exposure to sour gas, brine, or chemicals are commonplace. The alloy’s resistance to pitting, stress corrosion cracking, and crevice corrosion makes it a reliable choice for subsea and topside equipment alike.

The marine, energy, and power generation industries also benefit from SS 17-4PH's robustness. In offshore platforms and coastal infrastructure, the alloy is used to produce load-bearing brackets, supports, and rotating equipment components where salt-laden atmospheres are a concern. In thermal and nuclear power facilities—particularly across India and Oman—the material supports critical components like turbine blades, boiler internals, and fasteners exposed to elevated temperatures and steam. Furthermore, its increasing adoption in medical and dental applications—including surgical tools and implant fixtures—demonstrates the alloy’s compatibility with biocompatibility standards and sterilization protocols.

Our extensive logistics network ensures timely and efficient delivery of SS 17-4PH round bars across our core supply regions: India, the UAE, KSA, Kuwait, Qatar, Oman, Iran, and Iraq. With a focus on quality assurance, material compliance, and client-specific customization, we support industries that demand the highest standards in metallurgical performance and supply chain dependability.

| STANDARD | UNS | WNR. |

|---|---|---|

| SS 17-4PH | S17400 | 1.4542 |

SS 17-4PH Square Bar

Stainless Steel 17-4PH Square Bar, UNS S17400 Square Bar, DIN 1.4542 Square Rod, ASME SA 276 SS 17-4PH Square Bar, Stainless Steel 17-4PH Polish Square Bar, SS 17-4PH Square Rod

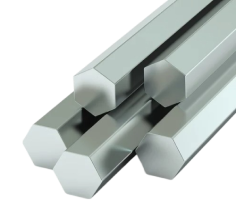

SS 17-4PH Hex Bar

ASME SA276 SS 17-4PH Hex Bar, ASTM A276 Stainless Steel 17-4PH Hex Bar, DIN 1.4542 Hex Bar, UNS S17400 Hex Bar, SS 17-4PH Hex Rod, SS 17-4PH Polish Hex Bar, SS 17-4PH Hex Rod

SS 17-4PH Rectangular Bar

Stainless Steel ASTM A276 17-4PH Rectangular Bar, UNS S17400 / DIN 1.4542 Rectangular Bar, ASME SA276 SS 17-4PH Rectangular Rod, SS 17-4PH Rectangle Rod, Stainless 17-4PH Rectangle Bar, Polish SS 17-4PH Rectangular Bar Supplier

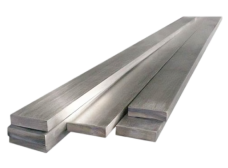

SS 17-4PH Flat Bar

DIN 1.4542 Flat Bar, UNS S17400 Flat Bar, ASME SA 276 Stainless Steel 17-4PH Flat Bar, ASTM A276 17-4PH SS Flat Rod, SS 17-4PH Polish Flat Bar

SS 17-4PH Bright Bar

ASTM A276 17-4PH Stainless Steel Bright Bar, SS UNS S17400 Bright Bar, SS 17-4PH Bright Rod, SS 17-4PH Polish Bright Bar

SS 17-4PH Forged Bar

UNS S17400 Forged Bar, Stainless Steel 17-4PH Forged Rod, ASTM A276 17-4PH Stainless Steel Polish Forged Bar, ASME SA 276 SS 17-4PH Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 17-4PH Round Bar

| Grade | C | P | Si | Ni | Cu | Fe | Mn | S | Cr |

|---|---|---|---|---|---|---|---|---|---|

| SS 17-4 PH | 0.07 max | 0.04 max | 1.0 max | 3.0 - 5.0 max | 3.0 - 5.0 max | Bal | 1.0 max | 0.03 | 15.0 - 17.5 |

Mechanical Properties Of Stainless Steel 17-4PH Round Bar

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Rockwell Hardness |

|---|---|---|---|

| 160,000 | 145,000 | 5% | C35 |

Our SS 17 4PH Round Bars Rods are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry