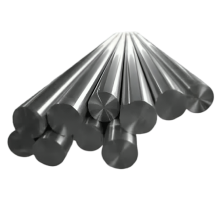

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

SS 430 Round Bars are crafted from a ferritic stainless steel grade known for its high chromium content, typically around 16-18%, which imparts excellent corrosion resistance, particularly in mildly corrosive environments. Unlike austenitic grades, SS 430 does not contain significant amounts of nickel, making it more cost-effective while still delivering satisfactory mechanical properties. This chromium-rich alloy exhibits good oxidation resistance and is highly resilient under atmospheric conditions and in fresh water, mild acids, and organic materials. SS 430 has a moderate tensile strength, generally ranging from 450 MPa to 600 MPa, and demonstrates good ductility and formability, which makes it an ideal material for machining and fabrication processes.

The metallurgical composition of SS 430 includes carbon content typically limited to 0.12% or less, ensuring enhanced weldability and reduced risk of intergranular corrosion. A standout feature of this stainless steel grade is its strong magnetic response coupled with high resistance to stress corrosion cracking. The round bar or rod form is manufactured through hot rolling or cold finishing processes, resulting in precise dimensional tolerances and smooth surface finishes that are critical for high-precision engineering applications. Depending on the specific requirements, SS 430 round bars are available in a variety of diameters and lengths, with options for customized cutting and polishing.

Given its balanced mechanical strength, corrosion resistance, and affordability, SS 430 round bars are widely adopted as a practical alternative to more expensive stainless steel grades in environments that do not demand extreme chemical resistance. These properties make it an excellent material for applications that prioritize structural integrity, magnetic response, and aesthetic appeal without compromising on cost-efficiency. This technical robustness, combined with adaptability in processing, positions SS 430 round bars as a preferred choice across multiple sectors, particularly in India and GCC markets including the UAE, KSA, Oman, Kuwait, Qatar, Iran, and Iraq.

Applications of SS 430 Round Bars and Rods

SS 430 round bars and rods are utilized across a diverse array of applications where moderate corrosion resistance and structural strength are paramount. In architectural and decorative applications, these bars are extensively used in interior trims, handrails, balustrades, and appliance panels due to their high polishability and mirror-like surface finish. Blending visual elegance with robust performance, these bars are well-suited for residential and commercial settings, delivering an optimal mix of style and reliability. SS 430 is ideal for magnetic applications because of its ferritic structure, which provides strong magnetic permeability. This makes it highly effective in manufacturing motor housings, transformer cores, and various electrical hardware where reliable magnetic performance is crucial. Its stability under moderate temperatures and cost-efficiency further enhance its value in tech and industrial setups.

In the manufacturing sector, SS 430 round bars are used for producing equipment parts that operate in mildly corrosive or elevated temperature conditions. This includes fasteners, shafts, valves, and machine components that benefit from the alloy’s good machinability and resistance to scaling up to 870°C. The food and beverage industry often utilizes SS 430 for components like support structures, conveyor systems, and utensils, especially where hygiene and resistance to organic acids are critical. Furthermore, SS 430 is also employed in the automotive industry for producing trim components, muffler parts, and fuel tank liners due to its favorable thermal and magnetic properties.

Additionally, SS 430 round rods find a niche in the fabrication of home and industrial kitchen equipment, including sinks, cooktops, and dishwashers. Their ability to withstand regular cleaning and exposure to detergents and water without significant degradation makes them ideal for such applications. Stainless steel 430’s non-hardenable nature also allows for easier forming and welding, making it a go-to material for products that require intricate shaping or custom fabrication. This adaptability extends to tooling applications in light-duty manufacturing and customized component development for OEM suppliers across regions including India and the Middle East.

Industry Use and Regional Supply Dynamics

SS 430 round bars/rods are in consistent demand across multiple industrial domains due to their balanced performance and economic viability. In India and across the Gulf region, the construction sector widely uses these bars for both structural support and visually appealing architectural elements. Their durability in atmospheric and freshwater environments aligns well with infrastructure development projects, both public and private. In the oil and gas sectors of Kuwait, KSA, and Iraq, SS 430 is frequently selected for secondary structural applications and processing equipment that face limited exposure to corrosive agents, offering a cost-effective solution without compromising reliability.

In the UAE and Qatar, industries such as HVAC, consumer appliances, and water treatment facilities integrate SS 430 round rods in systems that require moderate resistance to oxidation and chemical wear. Their use in manufacturing equipment, structural supports, and magnetic assemblies has been increasing due to both performance and cost considerations. The growing adoption of stainless steel in modular furnishings, architectural railings, and urban infrastructure fittings has sparked increased market demand in regions such as Oman and Iran. Here, the alloy’s surface finish and formability are highly valued for both function and form.

From a logistics and supply standpoint, our distribution network ensures reliable availability and tailored supply solutions across all key markets in India, UAE, KSA, Kuwait, Qatar, Oman, Iran, and Iraq. Our SS 430 round bars and rods are sourced and processed to comply with international standards, with stringent quality checks to meet client-specific engineering requirements. Whether for bulk industrial use, infrastructure development, or customized manufacturing needs, our products offer consistency, performance, and value. With growing regional demand driven by industrial diversification and urban expansion, SS 430 continues to play a critical role in shaping both local and export-oriented production ecosystems.

| STANDARD | UNS | WNR. | JIS |

|---|---|---|---|

| SS 430 | S43000 | 1.4016 | SUS 430 |

SS 430 Square Bar

Stainless Steel 430 Square Bar, UNS S43000 Square Bar, DIN 1.4016 Square Rod, ASME SA 276 SS 430 Square Bar, Stainless Steel 430 Polish Square Bar, SS 430 Square Rod

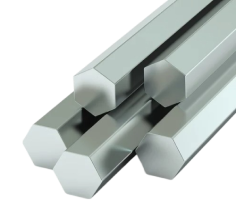

SS 430 Hex Bar

ASME SA276 SS 430 Hex Bar, ASTM A276 Stainless Steel 430 Hex Bar, DIN 1.4016 Hex Bar, UNS S43000 Hex Bar, SS 430 Hex Rod, SS 430 Polish Hex Bar, SS 430 Hex Rod

SS 430 Rectangular Bar

Stainless Steel ASTM A276 430 Rectangular Bar, UNS S43000 / DIN 1.4016 Rectangular Bar, ASME SA276 SS 430 Rectangular Rod, SS 430 Rectangle Rod, Stainless 430 Rectangle Bar, Polish SS 430 Rectangular Bar Supplier

SS 430 Flat Bar

DIN 1.4016 Flat Bar, UNS S43000 Flat Bar, ASME SA 276 Stainless Steel 430 Flat Bar, ASTM A276 430 SS Flat Rod, SS 430 Polish Flat Bar

SS 430 Bright Bar

ASTM A276 430 Stainless Steel Bright Bar, SS UNS S43000 Bright Bar, SS 430 Bright Rod, SS 430 Polish Bright Bar

SS 430 Forged Bar

UNS S43000 Forged Bar, Stainless Steel 430 Forged Rod, ASTM A276 430 Stainless Steel Polish Forged Bar, ASME SA 276 SS 430 Forged Bar

Stainless Steel Round Bar Specification : :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Chemical Composition of Stainless Steel 430 Round Bar

| Grade | C | Mn | Si | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| 430 | 0.12 max | 1.00 max | 1.00 max | 0.040 max | 0.030 max | 16.0 - 18.0 | 0.75 max |

Mechanical Properties Of Stainless Steel 430 Round Bar

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | |||

| 450 | 205 | 22 | 89 | 183 |

Our SS 430 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry