Titanium Flanges Specification :

ASTM B363 / ASME SB363

Titanium Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Titanium Gr 5 Flanges are engineered to meet the performance demands of high-pressure and high-temperature industrial environments. Developed from an advanced titanium alloy composed of aluminum, vanadium, iron, and oxygen, these flanges combine excellent strength, corrosion resistance, and thermal stability. Their superior material composition allows them to perform efficiently across diverse structural and mechanical applications. These flanges are manufactured in a wide range of sizes, wall thicknesses, and face types, including slip-on, blind, weld neck, threaded, socket weld, lap joint, long weld neck, ring-type joint (RTJ), spectacle blinds, and plate flanges. Each product is processed with precision to achieve a smooth finish, tight dimensional tolerance, and long-lasting durability, making them suitable for highly sensitive and critical applications. The availability of Titanium Gr 5 Flanges in custom specifications at competitive prices ensures their growing demand across major markets such as India, the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq.

Technical Overview

Titanium Gr 5 Flanges are produced in accordance with globally recognized standards such as ASTM B363 and ASME SB363, which define the mechanical and chemical properties necessary for high-integrity flange components. With a chemical composition primarily based on titanium, augmented with 6% aluminum and 4% vanadium, this grade—also known as Ti-6Al-4V—offers a combination of high tensile strength, light weight, and resistance to corrosion in harsh environments. These properties are essential for installations exposed to seawater, chemicals, acids, or extreme atmospheric conditions. Titanium Gr 5 Flanges demonstrate excellent formability and weldability, which enables them to be shaped and joined without compromising structural performance. Withstanding continuous temperatures up to 400°C, they are well-suited for thermal systems requiring both stability and endurance. All flanges undergo rigorous inspection processes including mechanical testing, chemical analysis, dimensional verification, and surface integrity checks to ensure reliability and conformity. The finished products are supported with full documentation, such as material test certificates, guarantee letters, and third-party inspection reports, offering complete traceability and confidence to end users across sectors.

Applications & Industry Use

Titanium Gr 5 Flanges are widely adopted in multiple industries where precision, reliability, and resistance to environmental damage are non-negotiable. In the aerospace sector, they are used in engine components, airframes, and hydraulic systems due to their exceptional strength-to-weight ratio and resistance to temperature extremes. Within the marine and offshore industries, these flanges provide long-term durability against seawater corrosion, making them ideal for offshore platforms, undersea pipelines, and desalination facilities. In oil and gas operations, Gr 5 Titanium Flanges are employed in exploration rigs, refineries, and pressure control systems where exposure to sour gases and high-pressure fluids is common. Chemical and petrochemical industries rely on these flanges in reactors, distillation units, and acid storage systems, benefiting from the material’s inertness to aggressive chemical reactions. Power generation facilities also incorporate Titanium Gr 5 Flanges in boilers, heat exchangers, and turbine enclosures, where they maintain mechanical integrity under high thermal loads. Additionally, industries such as pulp and paper, mining, and desalination plants integrate these flanges into processing systems that demand prolonged exposure to abrasive or acidic materials. Their corrosion resistance, ease of fabrication, and adaptability make them a preferred choice for engineers and procurement managers across all major industrial sectors in the Middle East and India.

| STANDARD | UNS | WNR. |

|---|---|---|

| Titanium Gr 5 | R56400 | 3.7165 |

Titanium Alloy Gr 5 Slip On Flanges

Titanium Gr 5 SORF Flanges, UNS R56400 Slip On Flanges, DIN 3.7165 SORF Flanges, ASME SB 363 Ti Alloy Gr 5 Slip-on Raised Face Flanges

Titanium Gr 5 Weld Neck Flanges

ASME SB363 Titanium Gr 5 WNRF Flanges, ASTM B363 Ti Alloy Gr 5 Weld Neck Flanges, DIN 3.7165 Weld Neck Flanges, UNS R56400 Weld Neck Raised Face Flanges

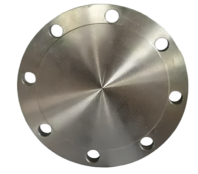

Ti Alloy Grade 5 Blind Flanges

ASTM B363 Titanium Gr 5 Blind Flanges, UNS R56400 / DIN 3.7165 Blind Flanges, ASME SB363 Titanium Alloy Gr 5 BLRF Flanges, Gr 5 Titanium Blind Raised Face Flanges Supplier

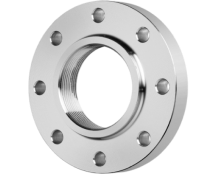

Titanium Gr 5 Threaded Flanges

DIN 3.7165 Threaded Flanges, UNS R56400 Screwed Flanges, ASME SB 363 Ti Alloy Gr 5 Threaded Flanges, ASTM B363 Titanium Gr 5 Threaded Flanges

Titanium Alloy Gr 5 Socket Weld Flanges

ASTM B363 Ti Alloy Gr 5 Socket Weld Flanges, Titanium UNS R56400 Socket Weld Flanges, Alloy DIN 3.7165 Socket Weld Flanges

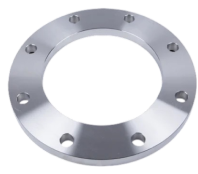

Titanium Gr 5 Lap Joint Flanges

UNS R56400 Lap Joint Flanges, Titanium Gr 5 Lap Joint Flanges, ASTM B363 Grade 5 Titanium Lap Joint Flanges, ASME SB363 Titanium Alloy Gr 5 Lap Joint Flanges

Titanium Alloy Gr-5 Ring Type Joint Flange

UNS R56400 Ring Type Joint Flange, ANSI B16.5 Titanium Gr 5 RTJ Flanges, ASTM B363 Titanium Gr 5 Ring Type Joint Flanges, ASME SB363 Titanium Gr 5 Ring Type Joint Flanges

Titanium Gr 5 Orifice Flanges

UNS R56400 Orifice Flanges, B16.36 Titanium Gr 5 Orifice Flanges, ASTM B363 Ti Alloy Gr 5 Orifice Flanges, ASME SB 363 Titanium Alloy Gr 5 Orifice Flanges

Titanium Alloy Gr 5 Long Weld Neck Flanges

UNS R56400 Long Weld Neck Flanges, Titanium 3.7165 Long Weld Neck Flanges, ASTM B363 Titanium Gr 5 Long Weld Neck Flanges, ASME SB 363 Titanium Gr 5 Long Weld Neck Flanges

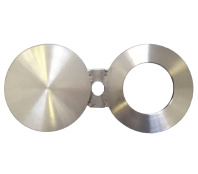

Titanium Gr 5 Spectacle Blind Flanges

UNS R56400 Spectacle Blind Flanges, ANSI / ASME B16.5 Titanium Gr 5 Spectacle Blind Flanges, ASTM B363 Titanium Gr 5 Spectacle Blind Flanges, ASME SB 363 Titanium Gr 5 Spectacle Blind Flanges

Titanium Gr 5 Forged Flanges

UNS R56400 Forged Flanges, B16.5 Titanium Gr 5 Forged Flanges, ASTM B363 Titanium Gr 5 Forged Flanges, ASME SB363 Titanium Gr 5 Forged Flanges

Titanium Gr 5 Plate Flanges

UNS R56400 Plate Flanges, ANSI B16.5 Titanium Gr 5 Plate Flanges, ASTM B363 Titanium Gr 5 Plate Flanges, ASME SB363 Titanium Alloy Gr 5 Plate Flanges

Titanium Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Titanium Gr 5 Flanges

| Al | Fe | O | Ti | V |

|---|---|---|---|---|

| 6 | 0.25 | 0.2 | 90 | 4 |

Mechanical Properties Of Titanium Gr 5 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Physical Properties of Titanium Gr 5 Flanges

| Physical Properties | Metric | English |

|---|---|---|

| Density | 4.43 g/cc | 0.16 lb/in³ |

Our Titanium Gr 5 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry