Titanium Flanges Specification :

ASTM B363 / ASME SB363

Titanium Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Titanium Gr 9 Flanges are widely trusted in high-performance industries for their rare balance of strength, corrosion resistance, weldability, and formability. This unique positioning makes it an ideal choice for applications that demand moderate strength with superior fabrication flexibility and durability.

Designed for challenging environments, Titanium Gr 9 Flanges deliver consistent performance in high-pressure systems, corrosive media, and elevated temperatures, making them a dependable solution for long-term industrial operations.

Available Types & Design Flexibility

To meet diverse engineering requirements, Titanium Gr 9 Flanges are manufactured in multiple configurations, including:

These flanges are available in custom dimensions, pressure classes, and face types, allowing seamless integration into complex piping and pressure systems. Precision machining ensures tight tolerances, leak-free connections, and excellent load distribution across joints.

Standards, Quality & Custom Manufacturing

Each Titanium Gr 9 Flange is produced using premium-grade raw materials and manufactured in compliance with ASTM B363 and ASME SB363 specifications. This ensures mechanical and chemical consistency across every batch.

To guarantee reliability, all flanges undergo rigorous quality checks, including:

Complete traceability and documentation, including material test certificates and inspection reports, are provided with every shipment. Custom manufacturing based on client drawings or project-specific requirements is fully supported while maintaining strict adherence to international safety and quality norms.

Technical Overview of Titanium Gr 9 Flanges

Titanium Gr 9 is an alpha-beta titanium alloy (UNS R56320 / DIN 3.7195) known for its excellent strength-to-weight ratio, corrosion resistance, and ductility. Compared to lower titanium grades, it offers improved tensile strength while retaining exceptional formability and weldability.

Key technical advantages include:

These qualities make Titanium Gr 9 Flanges ideal for systems exposed to chemical attack, pressure variation, and long operational cycles without compromising structural integrity.

Applications & Industry Use

Titanium Gr 9 Flanges are used across a wide range of industries where performance and durability are non-negotiable:

Their resistance to fatigue, ease of fabrication, and adaptability to custom designs also make them suitable for infrastructure projects, industrial machinery, and precision engineering applications.

Global Supply & Regional Expertise

With a strong manufacturing base and a reliable logistics network, Titanium Gr 9 Flanges are supplied across India, UAE, Saudi Arabia (KSA), Kuwait, Qatar, Oman, Iran, and Iraq. This regional presence ensures timely delivery, project continuity, and dependable technical support for large-scale industrial operations and government infrastructure projects.

Why Choose Titanium Gr 9 Flanges?

If your application demands corrosion resistance, moderate strength, excellent weldability, and long service life, Titanium Gr 9 Flanges offer an optimal solution. Built to perform in aggressive environments and engineered to global standards, they deliver consistent reliability, reduced maintenance, and long-term value across critical industrial systems.

| STANDARD | UNS | WNR. |

|---|---|---|

| Titanium Gr 9 | R56320 | 3.7195 |

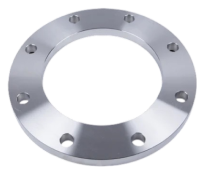

Titanium Alloy Gr 9 Slip On Flanges

Titanium Gr 9 SORF Flanges, UNS R56320 Slip On Flanges, DIN 3.7195 SORF Flanges, ASME SB 363 Ti Alloy Gr 9 Slip-on Raised Face Flanges

Titanium Gr 9 Weld Neck Flanges

ASME SB363 Titanium Gr 9 WNRF Flanges, ASTM B363 Ti Alloy Gr 9 Weld Neck Flanges, DIN 3.7195 Weld Neck Flanges, UNS R56320 Weld Neck Raised Face Flanges

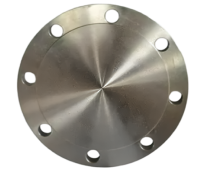

Ti Alloy Grade 9 Blind Flanges

ASTM B363 Titanium Gr 9 Blind Flanges, UNS R56320 / DIN 3.7195 Blind Flanges, ASME SB363 Titanium Alloy Gr 9 BLRF Flanges, Gr 9 Titanium Blind Raised Face Flanges Supplier

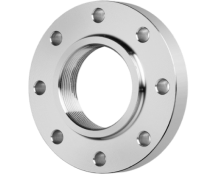

Titanium Gr 9 Threaded Flanges

DIN 3.7195 Threaded Flanges, UNS R56320 Screwed Flanges, ASME SB 363 Ti Alloy Gr 9 Threaded Flanges, ASTM B363 Titanium Gr 9 Threaded Flanges

Titanium Alloy Gr 9 Socket Weld Flanges

ASTM B363 Ti Alloy Gr 9 Socket Weld Flanges, Titanium UNS R56320 Socket Weld Flanges, Alloy DIN 3.7195 Socket Weld Flanges

Titanium Gr 9 Lap Joint Flanges

UNS R56320 Lap Joint Flanges, Titanium Gr 9 Lap Joint Flanges, ASTM B363 Grade 9 Titanium Lap Joint Flanges, ASME SB363 Titanium Alloy Gr 9 Lap Joint Flanges

Titanium Alloy Gr-9 Ring Type Joint Flange

UNS R56320 Ring Type Joint Flange, ANSI B16.9 Titanium Gr 9 RTJ Flanges, ASTM B363 Titanium Gr 9 Ring Type Joint Flanges, ASME SB363 Titanium Gr 9 Ring Type Joint Flanges

Titanium Gr 9 Orifice Flanges

UNS R56320 Orifice Flanges, B16.36 Titanium Gr 9 Orifice Flanges, ASTM B363 Ti Alloy Gr 9 Orifice Flanges, ASME SB 363 Titanium Alloy Gr 9 Orifice Flanges

Titanium Alloy Gr 9 Long Weld Neck Flanges

UNS R56320 Long Weld Neck Flanges, Titanium 3.7195 Long Weld Neck Flanges, ASTM B363 Titanium Gr 9 Long Weld Neck Flanges, ASME SB 363 Titanium Gr 9 Long Weld Neck Flanges

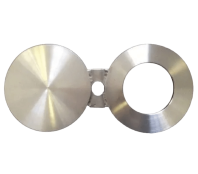

Titanium Gr 9 Spectacle Blind Flanges

UNS R56320 Spectacle Blind Flanges, ANSI / ASME B16.9 Titanium Gr 9 Spectacle Blind Flanges, ASTM B363 Titanium Gr 9 Spectacle Blind Flanges, ASME SB 363 Titanium Gr 9 Spectacle Blind Flanges

Titanium Gr 9 Forged Flanges

UNS R56320 Forged Flanges, B16.9 Titanium Gr 9 Forged Flanges, ASTM B363 Titanium Gr 9 Forged Flanges, ASME SB363 Titanium Gr 9 Forged Flanges

Titanium Gr 9 Plate Flanges

UNS R56320 Plate Flanges, ANSI B16.9 Titanium Gr 9 Plate Flanges, ASTM B363 Titanium Gr 9 Plate Flanges, ASME SB363 Titanium Alloy Gr 9 Plate Flanges

Titanium Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Titanium Gr 9 Flanges

| Al | Ti | V |

|---|---|---|

| max | max | max |

| 3 | 95 | 2.5 |

Mechanical Properties Of Titanium Gr 9 Flanges

| Element | Hardness Brinell | Hardness Knoop | Hardness Rockwell | Tensile Strength | Yield Strength |

|---|---|---|---|---|---|

| Titanium Gr. 9 | 256 | 278 | 24 | 620 Psi | 500 MPa |

Physical Properties of Titanium Gr 9 Flanges

| Physical Properties | Metric | English |

|---|---|---|

| Density | 4.48 g/cc | 0.162 lb/in³ |

Our Titanium Gr 9 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry