Titanium Flanges Specification :

ASTM B363 / ASME SB363

Titanium Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Titanium Grade 2 flanges are widely recognized for their outstanding balance of strength, corrosion resistance, and formability, making them one of the most versatile grades of commercially pure titanium. These flanges are ideal for use in environments where long-term resistance to oxidizing agents, chlorides, and seawater is critical. With excellent weldability and moderate mechanical strength, Titanium Grade 2 flanges are often chosen for systems where reliability under corrosive stress is more important than extreme tensile strength.

Manufactured in a range of types such as weld neck, blind, slip-on, socket weld, and threaded designs, these flanges are engineered to meet demanding industry standards and dimensional tolerances. Their use is prevalent in chemical processing plants, marine applications, desalination units, and power generation facilities. Our flanges are produced with precision and quality control that align with global standards and are supplied across key industrial regions, including India, UAE, Saudi Arabia (KSA), Kuwait, Qatar, Oman, Iran, and Iraq.

Technical Overview

Titanium Grade 2 (UNS R50400) is a commercially pure, unalloyed titanium grade containing a minimum of 99.2% titanium, with carefully controlled levels of oxygen, nitrogen, hydrogen, carbon, and iron. This composition offers a unique combination of moderate tensile strength and exceptional resistance to corrosion in both oxidizing and mildly reducing environments. The mechanical properties include a tensile strength in the range of 344 MPa (50 ksi) and yield strength around 275 MPa (40 ksi), with excellent elongation and impact toughness.

These flanges are particularly valued for their weldability, ease of fabrication, and biocompatibility. They perform well in service temperatures up to 400°C (752°F), maintaining structural integrity and chemical resistance under sustained operating pressures. The manufacturing process is carefully optimized to minimize contamination and preserve the titanium’s surface purity, making them suitable even for high-purity and high-pressure applications.

Applications & Industry Use

Grade 2 Titanium flanges are extensively used in sectors that demand a high level of corrosion resistance without compromising on cost-efficiency and fabrication flexibility. In the chemical and petrochemical industries, they are utilized in piping systems handling acidic and chloride-rich fluids, offering long-term protection against pitting and crevice corrosion. In the marine sector, these flanges are ideal for shipbuilding, offshore platforms, and desalination systems due to their excellent resistance to seawater and marine atmospheres.

In the aerospace industry, Grade 2 titanium flanges are used in airframe components, fuel systems, and hydraulic lines, where weight reduction and corrosion resistance are critical. They are also applied in power generation, particularly in heat exchangers and condenser systems, and in medical and pharmaceutical manufacturing, where non-reactivity and purity are essential. With an established supply network across India, UAE, KSA, Kuwait, Qatar, Oman, Iran, and Iraq, our solutions cater to diverse industrial demands with precision, reliability, and consistent quality.

| STANDARD | UNS | WNR. |

|---|---|---|

| Titanium Gr 2 | R50250 | 3.7025 |

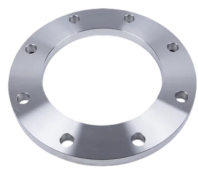

Titanium Alloy Gr 2 Slip On Flanges

Titanium Gr 2 SORF Flanges, UNS R50250 Slip On Flanges, DIN 3.7025 SORF Flanges, ASME SB 363 Ti Alloy Gr 2 Slip-on Raised Face Flanges

Titanium Gr 2 Weld Neck Flanges

ASME SB363 Titanium Gr 2 WNRF Flanges, ASTM B363 Ti Alloy Gr 2 Weld Neck Flanges, DIN 3.7025 Weld Neck Flanges, UNS R50250 Weld Neck Raised Face Flanges

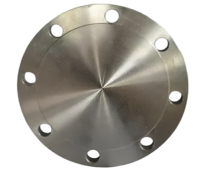

Ti Alloy Grade 1 Blind Flanges

ASTM B363 Titanium Gr 2 Blind Flanges, UNS R50250 / DIN 3.7025 Blind Flanges, ASME SB363 Titanium Alloy Gr 2 BLRF Flanges, Gr 2 Titanium Blind Raised Face Flanges Supplier

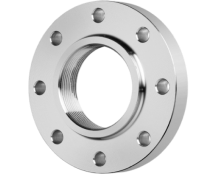

Titanium Gr 2 Threaded Flanges

DIN 3.7025 Threaded Flanges, UNS R50250 Screwed Flanges, ASME SB 363 Ti Alloy Gr 2 Threaded Flanges, ASTM B363 Titanium Gr 2 Threaded Flanges

Titanium Alloy Gr 2 Socket Weld Flanges

ASTM B363 Ti Alloy Gr 2 Socket Weld Flanges, Titanium UNS R50250 Socket Weld Flanges, Alloy DIN 3.7025 Socket Weld Flanges

Titanium Gr 2 Lap Joint Flanges

UNS R50250 Lap Joint Flanges, Titanium Gr 2 Lap Joint Flanges, ASTM B363 Grade 1 Titanium Lap Joint Flanges, ASME SB363 Titanium Alloy Gr 2 Lap Joint Flanges

Titanium Alloy Gr-1 Ring Type Joint Flange

UNS R50250 Ring Type Joint Flange, ANSI B16.5 Titanium Gr 2 RTJ Flanges, ASTM B363 Titanium Gr 2 Ring Type Joint Flanges, ASME SB363 Titanium Gr 2 Ring Type Joint Flanges

Titanium Gr 2 Orifice Flanges

UNS R50250 Orifice Flanges, B16.36 Titanium Gr 2 Orifice Flanges, ASTM B363 Ti Alloy Gr 2 Orifice Flanges, ASME SB 363 Titanium Alloy Gr 2 Orifice Flanges

Titanium Alloy Gr 2 Long Weld Neck Flanges

UNS R50250 Long Weld Neck Flanges, Titanium 3.7025 Long Weld Neck Flanges, ASTM B363 Titanium Gr 2 Long Weld Neck Flanges, ASME SB 363 Titanium Gr 2 Long Weld Neck Flanges

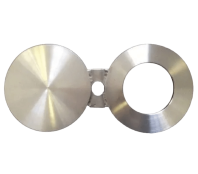

Titanium Gr 2 Spectacle Blind Flanges

UNS R50250 Spectacle Blind Flanges, ANSI / ASME B16.5 Titanium Gr 2 Spectacle Blind Flanges, ASTM B363 Titanium Gr 2 Spectacle Blind Flanges, ASME SB 363 Titanium Gr 2 Spectacle Blind Flanges

Titanium Gr 2 Forged Flanges

UNS R50250 Forged Flanges, B16.5 Titanium Gr 2 Forged Flanges, ASTM B363 Titanium Gr 2 Forged Flanges, ASME SB363 Titanium Gr 2 Forged Flanges

Titanium Gr 2 Plate Flanges

UNS R50250 Plate Flanges, ANSI B16.5 Titanium Gr 2 Plate Flanges, ASTM B363 Titanium Gr 2 Plate Flanges, ASME SB363 Titanium Alloy Gr 2 Plate Flanges

Titanium Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Titanium Gr 2 Flanges

| C | Fe | H | N | O | Ti |

|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.015 | 0.03 | 0.18 | 99.5 |

Mechanical Properties Of Titanium Gr 2 Flanges

| Grade | Tensile (ksi) | Yield Strength (ksi) | Elongation % |

|---|---|---|---|

| Titanium Gr 1 | 240 | 170 | 24 |

Physical Properties of Titanium Gr 1 Flanges

| Physical Properties | Metric | English |

|---|---|---|

| Density | 4.51 g/cc | 0.163 lb/in³ |

Our Titanium Gr 2 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry