Specification :

ASTM A335 / ASME SA335

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

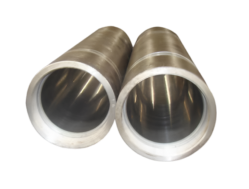

Alloy Steel P91 Pipes & Tubes are manufactured using advanced production technologies and high-grade raw materials to meet stringent international standards. Designed for strength, reliability, and adaptability, these components cater to a broad range of industrial applications across national and global markets.

Composed primarily of chromium and molybdenum, along with vanadium, niobium, and other alloying elements, P91 Pipes & Tubes exhibit exceptional thermal stability, corrosion resistance, and mechanical strength. These elements enhance tensile and creep strength, particularly when subjected to cold working processes, making them an ideal choice for high-stress environments.

Available Forms and Sizes: Seamless, welded, and fabricated variants, Offered in single random, double random, and custom lengths, Supplied in a variety of diameters and wall thicknesses.

These pipes are engineered to be easily molded into desired configurations as per customer requirements, ensuring versatility across diverse industrial sectors.

It’s Standards and Specifications: ASTM A/SA 335 Grade P91 Seamless Pipes, DIN 1.4903, UNS K91560, EN X10CrMoVNb9-1, Chrome Moly P91

Industrial Applications: Alloy Steel P91 Pipes & Tubes are extensively employed in sectors where operational temperatures vary from extremely low to exceedingly high. These include - Power generation plants, Petrochemical and oil & gas industries, Fossil fuel-based energy systems, Heat exchangers and boiler components, Marine engineering and offshore applications.

The high resistance to oxidation, pressure, and heat ensures that these pipes maintain performance integrity even under the most demanding conditions. Their ability to withstand elevated temperatures without compromising structural strength makes them a critical component in thermal and mechanical systems. And its key features like Excellent weldability and formability, Superior corrosion and oxidation resistance, High tensile and yield strength, Long service life with minimal maintenance and Cost-effective for high-efficiency operations.

Quality Assurance and Testing: To ensure consistency, each batch of P91 Pipes & Tubes undergoes comprehensive quality checks. This includes, Flattening tests, Radiographic examination, Intergranular corrosion resistance tests, Pitting and mechanical property evaluations.

Both chemical composition and physical durability are verified to guarantee that the products meet or exceed required industry specifications.

With their unmatched combination of strength, thermal efficiency, and durability, Alloy Steel P91 Pipes & Tubes or P22 Pipes & Tubes stand out as a preferred solution for critical infrastructure and high-performance engineering applications worldwide.

| STANDARD | Werkstoff /DIN | UNS | EN |

|---|---|---|---|

| A335 Grade P91 | 1.4903 | K91560 | X10CrMoVNb9-1 |

Alloy Steel P91 Seamless Pipes

ASTM A/SA 335 Gr. P91 Alloy Steel Seamless Pipe, UNS K91560 Seamless Pipes, DIN 1.4903 Seamless Pipes, Grade P91 Seamless Alloy Steel Pipe

Chrome Moly P91 Seamless Pipes

CrMo P91 Seamless Pipes, P91 Chromium Molybdenum Steel Seamless Pipes, ASTM A335 P91 Chrome-Moly Seamless Pipe

Alloy Steel P91 High Pressure Pipes

ASTM A335 P91 Alloy Steel High pressure pipes Supplier, Alloy Steel Gr P91 Boiler Pipes Exporter, ASME SA 335 Grade P91 High Temperature Steel Pipes

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

Size :

1/8"NB TO 30"NB IN

Type :

Seamless / ERW / Welded / Fabricated Pipes

Form :

Round, Square, Rectangular, Oval, Hydraulic Etc

Length :

Single Random, Double Random & Required Length

End :

Plain End, Beveled End, Treaded

Schedules :

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Inspection, Test Reports :

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :

Sizes and Specifications other than above can be manufactured on request

Specifications :

ASTM B363 / ASME SB363

Dimensions :

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size :

Seamless Butt Weld Fittings : 1/2" - 10" | Welded Butt Weld Fittings : 1/2" - 48"

Schedule :

SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75

Bending Radius :

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Type :

Seamless / ERW / Welded / Fabricated

Thickness :

20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc.

Chemical Composition of Alloy Steel P91 Seamless Pipes And Tubes

| Grade | C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

|---|---|---|---|---|---|---|---|

| P91 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

Mechanical Properties Of ASME SA335 Alloy Steel P91 Pipe

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P91 | 585 min | 415 min | 20 min |

Our Alloy steel P91 Pipes and Tubes are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry