Specification :

ASTM A335 / ASME SA335

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

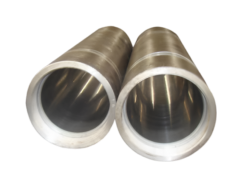

Alloy Steel P22 Pipes & Tubes are meticulously engineered to meet the rigorous demands of industries that rely on durability, structural integrity, and superior resistance to thermal and chemical stress. These components are manufactured with precision and are tailored to customer-specific requirements, offering both reliability and adaptability for varied industrial needs.

Recognized for their excellent mechanical and metallurgical properties, these pipes and tubes are composed of a robust alloy blend, typically including elements such as Chromium, Molybdenum, Iron, Copper, Titanium, and Zinc. This balanced composition ensures outstanding corrosion resistance, enhanced tensile strength, and thermal conductivity—critical attributes for high-temperature and high-pressure environments.

Standards & Grades: ASTM A/SA 335 Grade P22 Seamless Pipes, DIN 1.7380 Pipes, EN 10CrMo9-10 Seamless Pipes, UNS K21590, Chrome Moly P22 & Alloy 2 1/4Cr-1Mo.

These alloy steel pipes and tubes are subjected to rigorous quality assessments, including destructive and non-destructive testing, to guarantee structural consistency and long-term performance. With high yield strength and excellent weldability, they are ideal for operations involving bending, flanging, and other mechanical forming processes.

Applications Across Industries: Due to their strength and reliability, Alloy Steel P22 Pipes & Tubes find widespread use in, Power generation and boiler systems, Oil and gas pipelines, Petrochemical refineries, High-pressure steam lines, Aerospace and defense components, Structural frameworks in construction, Heat exchangers and pressure vessels & Durable metal furniture and architectural elements.

The thermal and corrosion resistance of these pipes ensures consistent performance under extreme working conditions. Their robust design and metallurgical precision also make them suitable for defense technologies and aerospace sectors, where failure is not an option. And its exceptional Features like High tensile strength and load-bearing capacity, Excellent resistance to oxidation and corrosive agents, Reliable performance in high-temperature conditions, Versatile fabrication options (cut-length, double random, custom), Polished surface finish for added mechanical integrity & Enhanced service life through superior alloy formulation.

Whether for structural support, pressure containment, or thermal conduction, Alloy Steel P22 Pipes & Tubes and P91 Pipes & Tubes deliver dependable performance and long-term value. Engineered with a focus on safety, resilience, and efficiency, they remain a trusted choice across sectors demanding material excellence.

| STANDARD | Werkstoff /DIN | UNS | EN |

|---|---|---|---|

| A335 Grade P22 | 1.7380 | K21590 | 10CrMo9-10 |

Alloy Steel P22 Seamless Pipes

ASTM A/SA 335 Gr. P22 Alloy Steel Seamless Pipe, UNS K21590 Seamless Pipes, DIN 1.7380 Seamless Pipes, Grade P22 Seamless Alloy Steel Pipe, Alloy Steel 2 1-4 Cr-1Mo Pipes

Chrome Moly P22 Seamless Pipes

CrMo P22 Seamless Pipes, P22 Chromium Molybdenum Steel Seamless Pipes, ASTM A335 P22 Chrome-Moly Seamless Pipe, Chrome Moly 2 1-4 Cr-1Mo Seamless Pipes

Alloy Steel P22 High Pressure Pipes

ASTM A335 P22 Alloy Steel High pressure pipes Supplier, Alloy Steel Gr P22 Boiler Pipes Exporter, ASME SA 335 Grade P22 High Temperature Steel Pipes

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

Size :

1/8"NB TO 30"NB IN

Type :

Seamless / ERW / Welded / Fabricated Pipes

Form :

Round, Square, Rectangular, Oval, Hydraulic Etc

Length :

Single Random, Double Random & Required Length

End :

Plain End, Beveled End, Treaded

Schedules :

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Inspection, Test Reports :

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :

Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Alloy Steel P22 Seamless Pipes And Tubes

| Grades | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P22 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

Mechanical Properties Of ASME SA335 Alloy Steel P22 Pipe

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P22 | 415 min | 205 min | 30 min |

Our Alloy steel P22 Tube Supplier are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry