Specification :

ASTM A335 / ASME SA335

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

A recognized leader in the manufacture and supply of Alloy Steel P9 Pipes & Tubes, we are committed to delivering superior-grade materials tailored to meet the diverse needs of our global clientele. Our comprehensive product range is available in various sizes and configurations, offering maximum flexibility for industrial applications.

Versatility in Form and Function

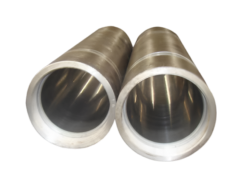

Alloy Steel P9 products encompass a wide selection, including welded pipes, ERW pipes, round pipes, rectangular pipes, and electro-polished pipes. Each type serves specific functional requirements and is engineered to deliver top performance. These pipes stand out for their smooth finish, contemporary design, robust build, and superior mechanical attributes.

Key performance features include, High tensile and yield strength, Exceptional heat resistance, Superior formability for bending, flanging, and welding, Resistance to corrosion, oxidation, and sulfidation, Cryogenic strength and magnetic properties & Resistance to abrasion and erosion.

Technical Standards and Specifications

Our offerings adhere to globally recognized standards and include, ASTM A/SA 335 GR. P9 Seamless Pipes, Chrome Moly P9 Pipes, UNS S50400 Pipes, DIN 1.7386 Grade Tubing, EN X11CrMo9-1 Pipes, 9Cr-1Mo Seamless Pipes

Applications Across Critical Industries

Due to their reliable performance and resilience, Alloy Steel P9 Pipes & Tubes, Alloy Steel P5 Pipes & Tubes are widely used in, Petroleum refining and exploration, Chemical and pharmaceutical processing, Power generation and boiler manufacturing, Pressure vessels, valves, heat exchangers, and industrial flanges, Construction and infrastructure projects.

These pipes are also extensively utilized in hydrocrackers, control plants, food preservation systems, and environments where resistance to oxidizing salt solutions—including those containing iron and copper chlorides—is essential.

Trusted Quality with Certified Assurance

Beyond supplying materials, we ensure full compliance and transparency by providing all necessary documentation and test certifications. Each batch undergoes comprehensive quality checks, including, Mechanical Testing, Micro and Macro Structural Analysis & Flattening and Bending Tests.

We take every measure to guarantee that the delivered products meet the highest standards of reliability and safety, making them ideal for even the most demanding industrial operations.

| STANDARD | Werkstoff /DIN | UNS | EN |

|---|---|---|---|

| A335 Grade P9 | 1.7386 | S50400 | X11CrMo9-1 |

Alloy Steel P9 Seamless Pipes

ASTM A/SA 335 Gr. P9 Alloy Steel Seamless Pipe, UNS S50400 Seamless Pipes, DIN 1.7386 Seamless Pipes, Grade P9 Seamless Alloy Steel Pipe, Alloy Steel 9Cr-1Mo Pipes

Chrome Moly P9 Seamless Pipes

CrMo P9 Seamless Pipes, P9 Chromium Molybdenum Steel Seamless Pipes, ASTM A335 P9 Chrome-Moly Seamless Pipe, Chrome Moly 9Cr-1Mo Seamless Pipes

Alloy Steel P9 High Pressure Pipes

ASTM A335 P9 Alloy Steel High pressure pipes Supplier, Alloy Steel Gr P9 Boiler Pipes Exporter, ASME SA 335 Grade P9 High Temperature Steel Pipes

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

Size :

1/8"NB TO 30"NB IN

Type :

Seamless / ERW / Welded / Fabricated Pipes

Form :

Round, Square, Rectangular, Oval, Hydraulic Etc

Length :

Single Random, Double Random & Required Length

End :

Plain End, Beveled End, Treaded

Schedules :

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Inspection, Test Reports :

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :

Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Alloy Steel P9 Seamless Pipes And Tubes

| Grade | C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P9 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00-10.00 | 0.90-1.10 |

Mechanical Properties Of ASME SA335 Alloy Steel P9 Pipe

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P9 | 380 min | 205 min | 30 min |

Our Alloy steel P9 Pipes are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry