Specification :

ASTM A335 / ASME SA335

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

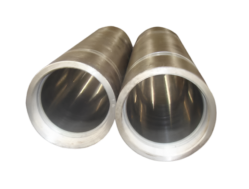

Alloy Steel P11 Pipes & Tubes are widely recognized for their high performance and adaptability, making them a preferred choice across a broad spectrum of industries nationwide. With a comprehensive product range, these pipes and tubes serve various structural and mechanical applications with precision.

Understanding Alloy Steel P11: Composition & Properties

Alloy steel, particularly the P11 grade, is a powerful engineering material known for its excellent formability, strength, and corrosion resistance. Crafted from a strategic blend of elements including iron, titanium, copper, zinc, and other strengthening agents, this alloy boasts superior mechanical and physical properties, such as: High tensile strength (approximately 205 MPa), Lightweight yet robust structure, Strong resistance to oxidation and rust, Excellent brazing characteristics & Good thermal and electrical conductivity

These attributes make Alloy Steel P11 not just a metal, but a material solution capable of being molded into various forms based on application demands. Its resistance to rust significantly enhances durability, extending the service life in both low and high-pressure environments.

Product Types & Industry Standards

The range of Alloy Steel P11 Pipes & Tubes includes: Seamless Pipes, Hot-Rolled Pipes, Welded and ERW Pipes and Custom-finished tubing in various shapes and thicknesses (2.0mm to 14mm)

It’s Key specifications include includes ASTM A335 / ASME SA335 Gr. P11, DIN 1.7335, EN 13CrMo4-5, UNS K11597, Alloy 1 ¼ Cr - ½ Mo Grade.

These pipes are designed to meet the toughest industrial requirements and conform to international quality benchmarks for safety and performance.

Applications Across Multiple Industries

Thanks to their strength, thermal stability, and rust resistance, Alloy Steel P11 Pipes & Tubes are employed in numerous sectors, such as: Construction and Infrastructure Projects, General Engineering Applications, Electrical and Communication Systems, High-Temperature Equipment, Heat Exchangers and Boilers and Chemical and Petrochemical Processing Plants.

Their adaptability makes them ideal for both structural frameworks and components that operate under high stress or temperature variations.

Product Form, Durability & Differentiation

These pipes are primarily supplied in hot-rolled form, offering enhanced workability without undergoing heat treatment. While this results in slightly lower strength compared to heat-treated alloys, the material compensates with improved conductivity and a smooth, uniform surface.

A common comparison arises between plates and sheets made from this alloy. The primary distinction lies in their thickness—plates are typically thicker and used in more demanding environments, while sheets offer flexibility for lightweight structures.

With their robust construction, multi-element composition, and industry-standard grades, Alloy Steel P11 Pipes & Tubes and Alloy steel P12 Pipes & Tubes deliver reliability, longevity, and efficiency in demanding environments. Whether it's structural reinforcement, heat conduction, or pressure handling, this alloy continues to be a cornerstone in modern engineering and manufacturing.

| STANDARD | Werkstoff /DIN | UNS | EN |

|---|---|---|---|

| A335 Grade P11 | 1.7335 | K11597 | 13CrMo4-5 |

Alloy Steel P11 Seamless Pipes

ASTM A/SA 335 Gr. P11 Alloy Steel Seamless Pipe, UNS K11597 Seamless Pipes, DIN 1.7335 Seamless Pipes, Grade P11 Seamless Alloy Steel Pipe, Alloy Steel 1 1/4 CR-1/2Mo Pipes

Chrome Moly P11 Seamless Pipes

CrMo P11 Seamless Pipes, P11 Chromium Molybdenum Steel Seamless Pipes, ASTM A335 P11 Chrome-Moly Seamless Pipe, Chrome Moly 1 1/4 CR-1/2Mo Seamless Pipes

Alloy Steel P11 High Pressure Pipes

ASTM A335 P11 Alloy Steel High pressure pipes Supplier, Alloy Steel Gr P11 Boiler Pipes Exporter, ASME SA 335 Grade P11 High Temperature Steel Pipes

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

Size :

1/8"NB TO 30"NB IN

Type :

Seamless / ERW / Welded / Fabricated Pipes

Form :

Round, Square, Rectangular, Oval, Hydraulic Etc

Length :

Single Random, Double Random & Required Length

End :

Plain End, Beveled End, Treaded

Schedules :

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Inspection, Test Reports :

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :

Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Alloy Steel P11 Seamless Pipes And Tubes

| Grade | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P11 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

Mechanical Properties Of ASME SA335 Alloy Steel P11 Pipe

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P11 | 415 min | 220 min | 30 min |

Our Alloy steel P11 Pipes Supplier are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry