Specification :

ASTM A335 / ASME SA335

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

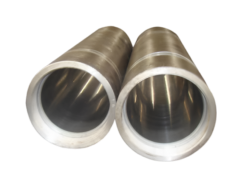

Alloy Steel P12 Pipes & Tubes are among the most advanced and reliable components in the category of alloy piping materials. Engineered with a precise combination of chemical elements and manufactured with meticulous attention to detail, these pipes and tubes are widely recognized for their exceptional consistency, strength, and durability.

Material Composition & Standard Compliance

Crafted from a carefully balanced composition of alloying elements, including chromium and molybdenum, Alloy Steel P12 is designed to deliver high-performance mechanical and thermal properties. Maintaining a consistent elemental composition is essential, as even minor deviations can significantly affect the structural integrity of the material. Therefore, strict adherence to industry standards such as ASTM A335 and ASME SA335 is maintained throughout the production process. These pipes are available in single random, double random, and custom cut lengths, typically up to 13,500 mm, offering flexible installation options. The surfaces are finished to a bright, polished sheen, enhancing both corrosion resistance and mechanical strength.

Available Grades & International Standards

The product line includes variants such as: ASTM A335 / ASME SA335 P12 Seamless Pipes, Chrome Moly P12 Pipes, DIN 1.7335 and EN 13CrMo44 Standards, UNS K11562 Pipes & Alloy 1Cr ½ Mo Seamless Pipes. These specifications ensure compatibility with demanding applications across global markets.

Multifunctional Applications Across Industries

Alloy Steel P12 Pipes & Tubes are extensively used in sectors requiring materials with high-temperature stability and structural reliability. These include: Aerospace and aviation (fuel tanks, exhaust systems), Automotive engineering (chassis, exhaust components), Appliance manufacturing, Structural applications in power and energy sectors & Thermal and electrical systems. The material’s excellent thermal conductivity, corrosion resistance, and mechanical strength make it ideal for use in high-pressure and high-temperature environments.

Design Features & Fabrication Capabilities

These pipes and tubes offer versatile form factors including foils, sheets, plates, bars, and more, catering to various fabrication needs. Their high workability allows for seamless cutting, drilling, machining, and welding, making them highly suitable for precision assembly and integration in critical applications. Each unit undergoes rigorous testing procedures—from tensile strength assessments to corrosion resistance and dimensional accuracy checks—to ensure optimal performance. This quality control process certifies the material for use in advanced industrial environments. Key Benefits at a Glance - Exceptional resistance to rust and corrosion, High dimensional accuracy and surface finish, Excellent thermal and electrical properties, Reliable performance under extreme conditions and Easy fabrication and customization.

Alloy Steel P12 Pipes & Tubes, offer a high-performance solution for industries that require exceptional strength, long-lasting durability, and superior resistance to corrosion. Whether used in aerospace, automotive, energy, or heavy machinery, these components are engineered to deliver long-term performance and consistent reliability in the most challenging environments.

| STANDARD | Werkstoff /DIN | UNS | EN |

|---|---|---|---|

| A335 Grade P12 | 1.7335 | K11562 | 13CrMo44 |

Alloy Steel P12 Seamless Pipes

ASTM A/SA 335 Gr. P12 Alloy Steel Seamless Pipe, UNS K11562 Seamless Pipes, DIN 1.7335 Seamless Pipes, Grade P12 Seamless Alloy Steel Pipe, Alloy Steel 1Cr 1/2Mo Pipes

Chrome Moly P12 Seamless Pipes

CrMo P12 Seamless Pipes, P12 Chromium Molybdenum Steel Seamless Pipes, ASTM A335 P12 Chrome-Moly Seamless Pipe, Chrome Moly 1Cr 1/2Mo Seamless Pipes

Alloy Steel P12 High Pressure Pipes

ASTM A335 P12 Alloy Steel High pressure pipes Supplier, Alloy Steel Gr P12 Boiler Pipes Exporter, ASME SA 335 Grade P12 High Temperature Steel Pipes

Specification :

ASTM A335 / ASME SA335

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

Size :

1/8"NB TO 30"NB IN

Type :

Seamless / ERW / Welded / Fabricated Pipes

Form :

Round, Square, Rectangular, Oval, Hydraulic Etc

Length :

Single Random, Double Random & Required Length

End :

Plain End, Beveled End, Treaded

Schedules :

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Inspection, Test Reports :

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :

Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Alloy Steel P12 Seamless Pipes And Tubes

| Grade | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|

| P12 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

Mechanical Properties Of ASME SA335 Alloy Steel P12 Pipe

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P12 | 415 min | 220 min | 30 min |

Our Alloy steel P12 Pipes are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry