Specification :

ASTM A691 / ASME SA691

Specification :

ASTM A691 / ASME SA691

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

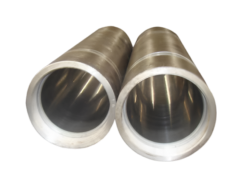

KVN specialize in supplying high-grade alloy steel welded pipes tailored for demanding industrial environments. These pipes are manufactured using advanced forming and welding techniques with a composition rich in chromium and low in carbon, offering superior structural integrity and resistance to corrosive elements. Known for their magnetic properties, exceptional ductility, and dimensional accuracy, these welded pipes are supplied in a variety of sizes ranging from 1/8” NB to 36” NB, and customized lengths and diameters to meet specific application requirements. Our distribution network spans across India, the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq, ensuring timely delivery and local support.

Technical Overview

Alloy steel welded pipes are engineered for exceptional performance under elevated temperature conditions, particularly in systems operating beyond 500°C. The alloy’s combination of chromium and molybdenum provides robust resistance to corrosion, thermal fatigue, and hydrogen embrittlement—common challenges in high-pressure and high-temperature operations. These pipes exhibit faster hydrogen diffusion in the ferritic phase, which further enhances their performance in marine and chemical environments. Conforming to global standards like ASTM A691 and ASME SA691, these A691 91 Cr or A691 9 Cr Welded pipes are subjected to rigorous inspections, including ultrasonic testing, eddy current checks, and hydrostatic pressure validation to ensure mechanical reliability and corrosion resistance.

Applications & Industry Use

Due to their mechanical strength and corrosion-resistant characteristics, alloy steel welded pipes are widely employed in critical infrastructure and industrial processes. Key sectors that utilize these pipes include offshore oil drilling, chemical and petrochemical industries, power generation plants, metal processing units, refineries, and automotive manufacturing. They are also found in gas processing systems and pharmaceutical production equipment. Every pipe undergoes a comprehensive testing regime that includes Rockwell hardness testing, intergranular corrosion testing, chemical analysis, PMI (positive material identification), and third-party certification to guarantee quality and performance. Designed for longevity and reliability, these pipes provide an ideal solution for high-stress industrial environments.

Alloy Steel Welded Pipes

ASTM A/SA 691 Alloy Steel Welded Pipe, Cr-Mo Welded Pipes, Welded Alloy Steel Pipe

Alloy Steel EFW Pipes

Alloy EFW Pipes, Chromium Molybdenum Steel EFW Pipes, ASTM A691 Chrome-Moly EFW Pipe

Alloy Steel High Pressure Pipes

ASTM A691 Alloy Steel High pressure pipes Supplier, Alloy Steel Boiler Pipes Exporter, ASME SA 691 High Temperature Steel Pipes

Specification :

ASTM A691 / ASME SA691

Dimensions :

ASTM, ASME and API

Outside Diameter :

6-2500mm; WT:1-200mm

Wall thickness :

0.3mm – 50 mm

Size :

1/8"NB TO 30"NB IN

Type :

Seamless / ERW / Welded / Fabricated Pipes

Form :

Round, Square, Rectangular, Oval, Hydraulic Etc

Length :

Single Random, Double Random & Required Length

End :

Plain End, Beveled End, Treaded

Schedules :

SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

Inspection, Test Reports :

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :

Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :

Sizes and Specifications other than above can be manufactured on request

Our A691 91 Cr Welded Pipe are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry