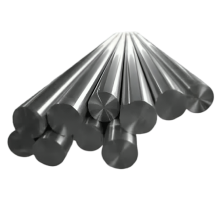

Inconel Round Bar Specification :

ASTM B166, ASME SB166

Inconel Round Bar Specification :

ASTM B166, ASME SB166

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Inconel 600 round bars are premium nickel-chromium alloy products engineered to perform reliably in high-temperature, corrosive, and high-pressure environments. Known for their exceptional resistance to oxidation and chemical attack, these bars are widely used across critical industries where material failure is not an option.

Whether specified as an Inconel 600 rod for machining or a finished Inconel alloy 600 round bar for structural and mechanical use, this material delivers long-term performance under extreme operating conditions.

Why Choose Inconel Alloy 600 Round Bars?

Inconel 600 is valued for its unique balance of strength, corrosion resistance, and thermal stability. Unlike conventional stainless steels, it maintains mechanical integrity even when exposed to aggressive chemicals and elevated temperatures.

Key advantages include:

These benefits make Inconel 600 round bars a trusted solution for demanding industrial applications.

Inconel 600 Round Bar Specifications & Standards

To ensure global compatibility and quality consistency, Inconel 600 bars are manufactured in accordance with international standards.

ASTM Standards: ASTM B166 Inconel 600 bar

Chemical Composition: High nickel content with chromium and iron for enhanced corrosion resistance

Mechanical Properties: High tensile strength, good ductility, and excellent fatigue resistance

Accurate Inconel 600 round bar specifications ensure suitability for critical engineering and safety-driven applications.

Available Forms & Sizes: To meet diverse fabrication and design needs, Inconel 600 round bar sizes are available in multiple forms:

These options allow engineers to select the right surface finish, dimensional tolerance, and strength characteristics for their project.

Industrial Applications of Inconel 600 Bars

Thanks to their durability and reliability, Inconel 600 bars are widely used in:

This versatility makes Inconel 600 a material of choice for mission-critical systems.

Inconel 600 Round Bars Supplier in Middle East

As a trusted Inconel 600 bars supplier, availability across key regions is crucial for project timelines. We support supply and export requirements across, UAE, Saudi Arabia, Qatar, Oman and Middle East.

Consistent quality, certified materials, and reliable logistics ensure seamless procurement for regional and international projects.

Choosing the right supplier ensures compliance, performance, and long-term value—especially in industries where material integrity defines success.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | GOST | OR | BS | JIS | EN |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | МНЖМц 28-2,5-1,5 | ЭИ868 | NA 13 | NCF 600 | NiCr15Fe |

| Inconel 601 | N06601 | 2.4851 | NC23FeA | XH60BT | ЭИ868 | NA 49 | NCF 601 | NiCr23Fe |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | ХН75МБТЮ | ЭИ602 | NA 21 | NCF 625 | NiCr22Mo9Nb |

| Inconel 718 | N07718 | 2.4668 | - | - | - | - | NCF 718 | - |

Inconel Alloy 600/601/625/718 Square Bar

Inconel 718 Square Bar, UNS N06600 / N06601 Square Bar, DIN 2.4856 Square Rod, ASME SB 166 Inconel Alloy 600 Square Bar, Inconel 601 Polish Square Bar, Alloy 600/601/625/718 Square Rod

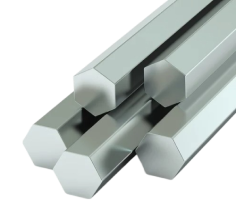

Inconel Alloy 600/601/625/718 Hex Bar

ASME SB166 Inconel Alloy 600 / 601 Hex Bar, ASTM B166 Inconel 625 Hex Bar, DIN 2.4668 Hex Bar, UNS N06601 Hex Bar, Inconel Alloy 625 / 718 Hex Rod, Inconel Alloy 600 Polish Hex Bar, Inconel Alloy 600/601/625/718 Hex Rod

Inconel Alloy 600 Rectangular Bar

Inconel ASTM B166 600 Rectangular Bar, UNS N06625 / DIN 2.4856 Rectangular Bar, ASME SB166 Inconel Alloy 601 Rectangular Rod, Inconel Alloy 718 Rectangle Rod, Alloy 600 Rectangle Bar, Polish Inconel Alloy 601 Rectangular Bar Supplier

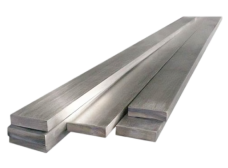

Inconel Alloy 600/601/625/718 Flat Bar

DIN 2.4851 Flat Bar, UNS N07718 Flat Bar, ASME SB 166 Inconel 600 Flat Bar, ASTM B166 601 Inconel Alloy Flat Rod, Inconel® Alloy 600/601/625/718 Polish Flat Bar

Inconel Alloy 600/601/625/718 Bright Bar

ASTM B166 601 Inconel Bright Bar, Inconel Alloy UNS N06625/ N07718 Bright Bar, Alloy 625 Bright Rod, Inconel Alloy 600/601/625/718 Polish Bright Bar

Inconel Alloy 600/601/625/718 Forged Bar

UNS N06601 Forged Bar, Inconel 600 Forged Rod, ASTM B166 625 Inconel Polish Forged Bar, ASME SB166 Inconel Alloy 718 Forged Bar

Inconel Round Bar Specification :

ASTM B166, ASME SB166

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

Surface Finishing :

Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

| Grade | Ni | Fe | C | Mn | Si | Cu | Cr | S | Mo | Co | Al | Ti | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 600 | 72.0 min | 6.0 - 10.0 | 0.15 max | 1.0 max | 0.5 max | 0.5 max | 14.0 - 17.0 | 0.015 max | - | - | - | - | - |

| 601 | 58.0 – 63.0 | Balance | 0.10 max | 1.0 max | 0.50 max | 1.0 max | 21.0 – 25.0 | 0.015 max | 8.0-10.0 | - | 1.0 – 1.7 | - | - |

| 625 | 58.0 max | 5.0 max | .10 max | .50 max | .50 max | - | 20.0 - 23.0 | .015 max | 8.0 - 10.0 | 1.0 max | .40 max | .40 max | 3.15 - 4.15 |

| 718 | 50 - 55 | - | 0.08 max | 0.35 max | 0.35 max | 0.3 max | 17 - 21 | .015 max | 2.8 - 3.3 | 1.0 max | - | - | - |

| Grade | Tensile (psi) | .2% Yield (psi) | Elongation (%) |

|---|---|---|---|

| 600 | 95,000 | 45,000 | 40 |

| 601 | 80,000 | 30,000 | 35 |

| Temp° F | Tensile (psi) | .2% Yield (psi) | Elongation in 2 “ (%) |

|---|---|---|---|

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Our Inconel 600 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry