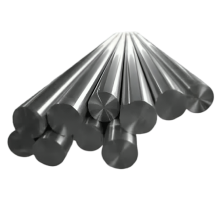

Incoloy Round Bar Specification :

ASTM B166, ASME SB166

Incoloy Round Bar Specification :

ASTM B166, ASME SB166

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Incoloy 800 Round Bars are renowned for their ability to withstand high temperatures, corrosive environments, and demanding industrial applications, making them one of the most reliable materials in modern engineering. Manufactured from a nickel-iron-chromium alloy with carefully balanced additions that enhance strength and stability, these round bars provide exceptional resistance to oxidation and carburization, even when exposed to prolonged thermal conditions. Industries such as petrochemical, chemical processing, power generation, and marine engineering depend on Incoloy 800 Round Bars to maintain performance where other alloys fail, ensuring critical systems operate efficiently and safely. Precision-driven manufacturing processes such as hot rolling, cold drawing, and heat treatment guarantee dimensional accuracy, consistent mechanical properties, and a flawless surface finish. This attention to detail not only delivers superior performance but also significantly extends equipment life, resulting in long-term cost savings and reduced downtime for industrial operators. In India, the legacy of Incoloy alloys spans decades, with their integration into energy, refinery, and metallurgical projects reinforcing trust in their durability and adaptability. By aligning technical expertise with stringent quality checks and global compliance standards, suppliers of Incoloy 800 Round Bars deliver more than just raw materials—they provide the foundation for sustainable industrial growth and the assurance of reliability in every application.

The value of Incoloy 800 Round Bars lies not just in their metallurgical composition but in their proven ability to adapt across industries where resilience is non-negotiable. These bars are widely utilized in high-temperature furnace components, heat exchangers, piping systems, steam generators, and superheaters, where they resist scaling, stress corrosion, and thermal fatigue. Their balanced nickel content ensures excellent resistance in reducing environments, while chromium imparts protection in oxidizing conditions, enabling long-term use in both acidic and alkaline settings. For manufacturers and engineers, this translates into unmatched versatility, dependable performance, and measurable cost efficiency. Trusted suppliers of Incoloy 800 Round Bars reinforce this value by adhering to internationally recognized standards such as ASTM, ASME, and DIN, while employing advanced testing methods that guarantee strength, safety, and consistency. Their reputation is built on decades of expertise, industry experience, and customer trust, positioning them as authoritative partners in global supply chains. By addressing real-world industrial challenges with precision-engineered solutions, Incoloy 800 Round Bars are more than materials—they are strategic assets that support efficiency, profitability, and long-term operational success. When combined with optimized, intent-focused digital information, this expertise ensures that decision-makers find accurate answers to their queries, gain confidence in their material choices, and connect with suppliers who embody transparency, quality, and credibility.

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | 1.4876 | N08800 | ЭИ670 | Z8NC32-21 | NCF 800 | NA 15 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | ЭИ670 | Z8NC33-21 | NCF 800H | NA 15(H) | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | ЭИ670 | - | NCF 800HT | NA 15(HT) | X8NiCrAlTi32-21 | XH32T |

| Incoloy 825 | 1.4876 | N08825 | 协袩703 | NFE30C20DUM | NCF 825 | NA 16 | NiCr21Mo | XH38BT |

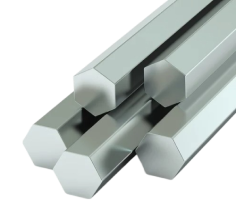

Incoloy Alloy 800/800H/800HT/825 Square Bar

Incoloy 825 Square Bar, UNS N08800 / N08810 Square Bar, DIN 1.4958 Square Rod, ASME SB 166 Incoloy Alloy 800 Square Bar, Incoloy 800H Polish Square Bar, Alloy 800/800H/800HT/825 Square Rod

Incoloy 800/800H/800HT/825 Hex Bar

ASME SB166 Incoloy Alloy 800 / 800H Hex Bar, ASTM B166 Incoloy 800HT Hex Bar, DIN 1.4876 Hex Bar, UNS N08810 Hex Bar, Incoloy 800HT / 825 Hex Rod, Incoloy 800 Polish Hex Bar, Incoloy Alloy 800/800H/800HT Hex Rod

Incoloy Alloy 800 Rectangular Bar

Incoloy ASTM B166 800 Rectangular Bar, UNS N08811 / DIN 1.4958 Rectangular Bar, ASME SB166 Incoloy Alloy 800H Rectangular Rod, Incoloy Alloy 825 Rectangle Rod, Alloy 800 Rectangle Bar, Polish Incoloy Alloy 800H Rectangular Bar Supplier

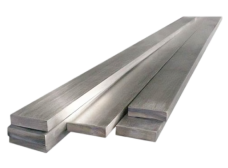

Incoloy Alloy 800/800H/800HT/825 Flat Bar

DIN 1.4859 Flat Bar, UNS N08825 Flat Bar, ASME SB 166 Incoloy 800 Flat Bar, ASTM B166 800H Incoloy Alloy Flat Rod, Incoloy® 800/800H/800HT/825 Polish Flat Bar

Incoloy Alloy 800/800H/800HT/825 Bright Bar

ASTM B166 800H Incoloy Bright Bar, Incoloy Alloy UNS N08811/ N08825 Bright Bar, Alloy 800HT Bright Rod, Incoloy Alloy 800/800H/800HT/825 Polish Bright Bar

Incoloy Alloy 800/800H/800HT/825 Forged Bar

UNS N08810 Forged Bar, Incoloy 800 Forged Rod, ASTM B166 800HT Incoloy Polish Forged Bar, ASME SB166 Incoloy Alloy 825 Forged Bar

Incoloy Round Bar Specification :

ASTM B166, ASME SB166

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Thickness :

50 mm to 6000 mm Long

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Alloy 825 | 0.05 max | 1.0 max | 0.5 max | 0.03 max | 1.5 – 3.0 | 22.0 min | 38.0 – 46.0 | 19.5 – 23.5 | 0.2max | 0.6 – 1.2 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Alloy 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

| Alloy 825 | 8.14 g/cm3 | 1400 C (2550 F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Our Incoloy 800 Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry