Inconel Flanges Specification :

ASTM B564 / ASME SB564

Inconel Flanges Specification :

ASTM B564 / ASME SB564

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Kvn steel &Engg. Co. is leading business enterprises in the field of metal alloy and flanges. We are the leading manufacturers, suppliers and exporters of Inconel 600/601/625/718 flanges as per the industrial requirements. Inconel 600/601/625/718 flanges are made up by Inconel alloy which is mixture of Nickel and Chromium. Inconel has got some excellent properties and that is the reason it is most sought alloy to manufacture different types of flanges. It is oxidation resistance and sustainable in open environment. Its temperature resistant is very high which means it is able to withstand high temperature of various manufacturing and processing industries. It is widely used in carburizing and chloride exposed environment and can sustain in harsh exposed environmental conditions, another property which makes it desirable is corrosion resistance. Inconel 600/601/625/718 flanges are sustainable in ammonia and nitrogen exposed environment, due to its high resistance and corrosive properties.

Alloy ASTM B564 600 Long Weld Neck Flanges, Inconel 601 Slip on Flanges, ASTM B564 Inconel 600/601/625/718 Blind Flanges Exporter, Inconel N06600 Ring Type Joint - RTJ Flanges, Inconel 600/601/625/718 Weld Neck Flanges, ASTM B564 Inconel 600/601/625/718 Flanges Supplier, Inconel N06601 Flanges, Alloy 600/601/625/718 Flanges Manufacturer in India.

Inconel 600 flanges are non-magnetic and welding favourable that makes it most desirable for iron and welding industries. It is used to manufacture thermocouple sheaths and EDC cracking tubes. Inconel 600 flanges are used in pressurized water reactors to control steam generator plates, as it has got high pressure sustainability property. It is also used in nuclear reactors to control various vessels and tubes. Other usage of Inconel600 flanges are roller hearths, retorts, muffles etc.

Inconel 601 flanges are used in industries like chemical processing, aerospace, heat treating industry, power generation, radiant tubes etc. Inconel 601 flanges are also used in petrochemical industries, oil and gas, pulp and paper manufacturing, textiles etc. There are different variety of Inconel 601 flanges are available as per requirements for example slip on flanges, spectacle blind flanges, orifice flanges, long welding neck flanges etc.

Alloy DIN 2.4816 Spectacle Blind Flanges Dealer, ASTM B564 Inconel 600 SORF Flanges, Inconel UNS N06625 Plate Flanges, UNS N07718 Socket Weld Trader, 601 Inconel Threaded Flanges Stockists, DIN 2.4851 Pipe Flanges, ASME SB564 Inconel 600/601/625/718 Flanges Supplier in India.

Inconel 625 flanges are mainly used in steam line piping, marine, chemical processing industries, nuclear power generation and in aerospace. These are available in different shapes and sizes for example pipe flanges, ring flanges, slip on flanges, socket weld flanges etc.

Inconel 718 flanges are used in oil drilling industries, petrochemicals, power generation, gas processing, in making chemical equipment, pharmaceutical equipment, heat exchangers and Condenser. It is evident that no industry can work with these flanges. Inconel flanges are part and parcel manufacturing and processing industries.

We as a company always ready to serve you and can manufacture Inconel 600/601/625/718 flanges as per your requirements.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | GOST | OR | BS | JIS | EN |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | N06600 | 2.4816 | NC15FE11M | МНЖМц 28-2,5-1,5 | ЭИ868 | NA 13 | NCF 600 | NiCr15Fe |

| Inconel 601 | N06601 | 2.4851 | NC23FeA | XH60BT | ЭИ868 | NA 49 | NCF 601 | NiCr23Fe |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | ХН75МБТЮ | ЭИ602 | NA 21 | NCF 625 | NiCr22Mo9Nb |

| Inconel 718 | N07718 | 2.4668 | - | - | - | - | NCF 718 | - |

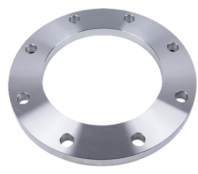

Alloy 600/601/625/718 Slip On Flanges

Inconel 600 SORF Flanges, UNS N06600 / N06601 Slip On Flanges, DIN 2.4856 SORF Flanges, ASME SB 564 Alloy 718 Slip-on Raised Face Flanges

Inconel 600/601/625/718 Weld Neck Flanges

ASME SB564 Inconel 601 WNRF Flanges, ASTM B564 Inconel 718 Weld Neck Flanges, DIN 2.4816 Weld Neck Flanges, UNS N07718 Weld Neck Raised Face Flanges

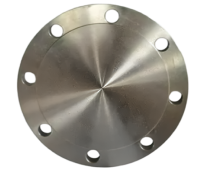

Alloy 600/601/625/718 Blind Flanges

ASTM B564 Inconel 625 Blind Flanges, UNS N06600 / DIN 2.4668 Blind Flanges, ASME SB564 Alloy 601 BLRF Flanges, Alloy 600 Blind Raised Face Flanges Supplier

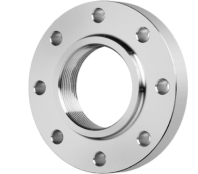

Alloy 600/601/625/718 Threaded Flanges

DIN 2.4851 Threaded Flanges, UNS N06600 Screwed Flanges, ASME SB 564 Alloy 625 Threaded Flanges, ASTM B564 Inconel 718 Threaded Flanges

Alloy 600/601/625/718 Socket Weld Flanges

ASTM B564 600 Inconel Socket Weld Flanges, Inconel UNS N06625/ N07718 Socket Weld Flanges, Alloy DIN 2.4816 Socket Weld Flanges

Inconel 600/601/625/718 Lap Joint Flanges

UNS N06600 Lap Joint Flanges, Inconel 601 Lap Joint Flanges, ASTM B564 625 Inconel Lap Joint Flanges, ASME SB564 Inconel Alloy 718 Lap Joint Flanges

Alloy 600/601/625/718 Ring Type Joint Flange

UNS N06601 Ring Type Joint Flange, ANSI B16.5 Inconel 600 RTJ Flanges, ASTM B564 Inconel 625 Ring Type Joint Flanges, ASME SB564 Alloy 718 Ring Type Joint Flanges

Inconel 600/601/625/718 Orifice Flanges

UNS N06625 Orifice Flanges, B16.36 Inconel 600/601/625/718 Orifice Flanges, ASTM B564 Alloy 600 Orifice Flanges, ASME SB 564 Inconel Alloy 601/625 Orifice Flanges

Alloy 600/601 Long Weld Neck Flanges

UNS N07718 Long Weld Neck Flanges, Inconel 2.4668 Long Weld Neck Flanges, ASTM B564 Inconel 600 Long Weld Neck Flanges, ASME SB 564 Inconel 625 Long Weld Neck Flanges

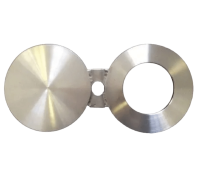

Inconel 600/601/625/718 Spectacle Blind Flanges

UNS N06601 Spectacle Blind Flanges, ANSI / ASME B16.5 Alloy 600 Spectacle Blind Flanges, ASTM B564 Alloy 625 Spectacle Blind Flanges, SB 564 Inconel 718 Spectacle Blind Flanges

Inconel 600/601/625/718 Forged Flanges

UNS N06625 Forged Flanges, B16.5 Alloy 600 Forged Flanges, ASTM B564 Inconel Alloy 601 Forged Flanges, ASME SB564 Alloy 718 Forged Flanges

Inconel 600/601/625/718 Plate Flanges

UNS N06600 Plate Flanges, ANSI B16.5 Inconel 601 Plate Flanges, ASTM B564 Inconel 625 Plate Flanges, ASME SB564 Inconel Alloy 718 Plate Flanges

Inconel Flanges Specification :

ASTM B564 / ASME SB564

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Inconel 600/601/625/718 Flanges

| Grade | Ni | Fe | C | Mn | Si | Cu | Cr | S | Mo | Co | Al | Ti | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 600 | 72.0 min | 6.0 - 10.0 | 0.15 max | 1.0 max | 0.5 max | 0.5 max | 14.0 - 17.0 | 0.015 max | - | - | - | - | - |

| 601 | 58.0 – 63.0 | Balance | 0.10 max | 1.0 max | 0.50 max | 1.0 max | 21.0 – 25.0 | 0.015 max | 8.0-10.0 | - | 1.0 – 1.7 | - | - |

| 625 | 58.0 max | 5.0 max | .10 max | .50 max | .50 max | - | 20.0 - 23.0 | .015 max | 8.0 - 10.0 | 1.0 max | .40 max | .40 max | 3.15 - 4.15 |

| 718 | 50 - 55 | - | 0.08 max | 0.35 max | 0.35 max | 0.3 max | 17 - 21 | .015 max | 2.8 - 3.3 | 1.0 max | - | - | - |

Mechanical Properties Of Inconel 600/601/625/718 Flanges

| Grade | Tensile (psi) | .2% Yield (psi) | Elongation (%) |

|---|---|---|---|

| 600 | 95,000 | 45,000 | 40 |

| 601 | 80,000 | 30,000 | 35 |

| Temp° F | Tensile (psi) | .2% Yield (psi) | Elongation in 2 “ (%) |

|---|---|---|---|

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|

| 625 | Psi – 135,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

| 718 | Psi – 135,000 , MPa – 930 | Psi – 70,000 , MPa – 482 | 45 % |

Our Inconel 600/601/625/718 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry