Incoloy Flanges Specification : :

ASTM A182 / ASME SA182

Incoloy Flanges Specification : :

ASTM A182 / ASME SA182

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

KVN Steel AndEngg. Co.is an exceptionally respectful company in the sector of business completely into inhabited in offering the collection of Incoloy 800/800HT/825 Flanges as a supplier, exporter, stockiest and producer all over the world customers at an affordable cost. We provide it in all customized sizes and shapes according to customer needs.

Incoloy 800/800Ht Flanges have some excellent features like tough design, durable, and high tensile strength, etc. For heat exchangers, carburizing equipment, nuclear-steam generator, processing pipe, and heat -element sheathing Incoloy 800 slip-on flanges are used. Incoloy 800HT Flanges is made up of content of nickel-iron-chromium. It also ensures the best high-temperature properties due to the aluminum and titanium contents present in it. Superior resistance to oxidation is offered due to the mixture of nickel and chromium.

Alloy ASTM B564 800 Long Weld Neck Flanges, Incoloy 800H Slip on Flanges, ASTM B564 Incoloy 800/800H/800HT/825 Blind Flanges Exporter, Incoloy N08800 Ring Type Joint - RTJ Flanges, Incoloy 800/800H/800HT/825 Weld Neck Flanges, ASTM B564 Incoloy 800/800H/800HT/825 Flanges Supplier, Incoloy N08810 Flanges, Alloy 800/800H/800HT/825 Flanges Manufacturer in India.

Incoloy 825 is an iron-chromium-nickel alloy with the components of titanium, copper, and molybdenum. It has improved resistance to aqueous corrosion in comparison to 800 alloys otherwise they both are the same. This alloy is used for pollution-control equipment, pickling equipment, acid production, oil and gas piping, and nuclear fuel reprocessing. Incoloy 825 is available in the form of a plate, sheet, bar, wire, weld wire, etc.

Alloy DIN 1.4876 Spectacle Blind Flanges Dealer, ASTM B564 Incoloy 800 SORF Flanges, Incoloy UNS N08811 Plate Flanges, UNS N08825 Socket Weld Trader, 800H Incoloy Threaded Flanges Stockists, DIN 1.4958 Pipe Flanges, ASME SB564 Incoloy 800/800H/800HT/825 Flanges Supplier in India.

Incoloy 800/800HT/825 Flanges have different characteristics. Some of the features of 800 Flanges are it has good corrosion resistance in the acidic environments, average resistance to the various sulfur-containing atmosphere, resistance to carburization and oxidation in high-temperature environments, high-temperature strength, and creep-rupture strength is also high. Features of 825 Flanges are extremely resistant to phosphoric and sulfuric acids, outstanding resistant to oxidizing and reducing acids, adequate resistance to localized attack like crevice and pitting corrosion, mechanical properties are also good at elevated and room temperature both approx. 1000 degreeF and the pressure wall is used at the permission of 800 degrees F temperature. The feature of Incoloy 800 HT is the same as 800.

Various tests are performed to maintain the benefits of Incoloy 800/800HT/825 Flanges. Tests such as Hardness test, flaring test, intergranular corrosion test, flattening test, etc. are performed. Packing will be depending on the size of the flanges. They are wrapped in a jute fabric or plastic also provided at the stop points and bundles end with metal sheet bundles tubes to avoid any loss.

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | 1.4876 | N08800 | ЭИ670 | Z8NC32-21 | NCF 800 | NA 15 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | ЭИ670 | Z8NC33-21 | NCF 800H | NA 15(H) | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | ЭИ670 | - | NCF 800HT | NA 15(HT) | X8NiCrAlTi32-21 | XH32T |

| Incoloy 825 | 2.4858 | N08825 | 协袩703 | NFE30C20DUM | NCF 825 | NA 16 | NiCr21Mo | XH38BT |

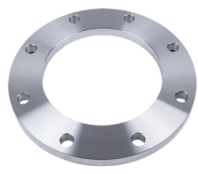

Alloy 800/800H/800HT/825 Slip On Flanges

Incoloy 800 SORF Flanges, UNS N08800 / N08810 Slip On Flanges, DIN 1.4859 SORF Flanges, ASME SB 564 Alloy 825 Slip-on Raised Face Flanges

Incoloy 800/800H/800HT/825 Weld Neck Flanges

ASME SB564 Incoloy 800H WNRF Flanges, ASTM B564 Incoloy 825 Weld Neck Flanges, DIN 1.4876 Weld Neck Flanges, UNS N08825 Weld Neck Raised Face Flanges

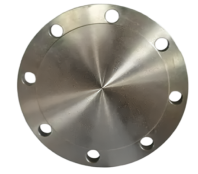

Alloy 800/800H/800HT/825 Blind Flanges

ASTM B564 Incoloy 800HT Blind Flanges, UNS N08825 / DIN 2.4858 Blind Flanges, ASME SB564 Alloy 800H BLRF Flanges, Alloy 800 Blind Raised Face Flanges Supplier

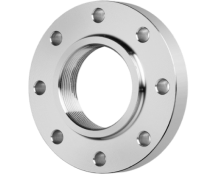

Alloy 800/800H/800HT/825 Threaded Flanges

DIN 1.4958 Threaded Flanges, UNS N08800 Screwed Flanges, ASME SB 564 Alloy 800HT Threaded Flanges, ASTM B564 Incoloy 825 Threaded Flanges

Alloy 800/800H/800HT/825 Socket Weld Flanges

ASTM B564 800 Incoloy Socket Weld Flanges, Incoloy UNS N08811/ N08825 Socket Weld Flanges, Alloy DIN 1.4876 Socket Weld Flanges

Incoloy 800/800H/800HT/825 Lap Joint Flanges

UNS N08800 Lap Joint Flanges, Incoloy 800H Lap Joint Flanges, ASTM B564 800HT Incoloy Lap Joint Flanges, ASME SB564 Incoloy Alloy 825 Lap Joint Flanges

Alloy 800/800H/800HT/825 Ring Type Joint Flange

UNS N08810 Ring Type Joint Flange, ANSI B16.5 Incoloy 800 RTJ Flanges, ASTM B564 Incoloy 800HT Ring Type Joint Flanges, ASME SB564 Alloy 825 Ring Type Joint Flanges

Incoloy 800/800H/800HT/825 Orifice Flanges

UNS N08811 Orifice Flanges, B16.36 Incoloy 800/800H/800HT/825 Orifice Flanges, ASTM B564 Alloy 800 Orifice Flanges, ASME SB 564 Incoloy Alloy 800H/800HT Orifice Flanges

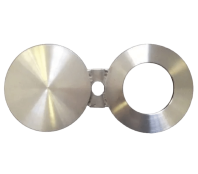

Incoloy 800/800H/800HT/825 Spectacle Blind Flanges

UNS N08810 Spectacle Blind Flanges, ANSI / ASME B16.5 Alloy 800 Spectacle Blind Flanges, ASTM B564 Alloy 800HT Spectacle Blind Flanges, SB 564 Incoloy 825 Spectacle Blind Flanges

Alloy 800/800H Long Weld Neck Flanges

UNS N08825 Long Weld Neck Flanges, Incoloy 2.4858 Long Weld Neck Flanges, ASTM B564 Incoloy 800 Long Weld Neck Flanges, ASME SB 564 Incoloy 800HT Long Weld Neck Flanges

Incoloy 800/800H/800HT/825 Forged Flanges

UNS N08811 Forged Flanges, B16.5 Alloy 800 Forged Flanges, ASTM B564 Incoloy Alloy 800H Forged Flanges, ASME SB564 Alloy 825 Forged Flanges

Incoloy 800/800H/800HT/825 Plate Flanges

UNS N08800 Plate Flanges, ANSI B16.5 Incoloy 800H Plate Flanges, ASTM B564 Incoloy 800HT Plate Flanges, ASME SB564 Incoloy Alloy 825 Plate Flanges

Incoloy Flanges Specification : :

ASTM A182 / ASME SA182

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Alloy 825 | 0.05 max | 1.0 max | 0.5 max | 0.03 max | 1.5 – 3.0 | 22.0 min | 38.0 – 46.0 | 19.5 – 23.5 | 0.2max | 0.6 – 1.2 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Alloy 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

| Alloy 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Our Incoloy 800/800H/800HT/825 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry