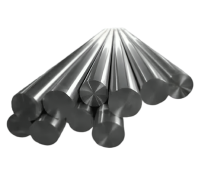

Duplex Steel Round Bar Specification :

ASTM A276 / A479, ASME SA276 / A479

Duplex Steel Round Bar Specification :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Length :

1 To 6 Meters, Custom Cut Length

Kvn Steels is a leading manufacturer, supplier and exporter of Duplex Steel Round Bars/Rods in Mumbai, India. We supply these duplex steel bars, rods in grades such as UNS S31803, and S32205. We manufacture these bars and rods using high quality raw materials and advanced technology in accordance to national and international quality standards. Duplex Steel round bars are available in various sizes, specifications, thickness, finishes, etc. we also manufacture them in custom made specifications to fulfill the requirements of various industries. Duplex Steel UNS S31803 Round bars are referred to as stainless steel austenitic-ferrite, with equal amounts of ferrite and austenite. Since they have both austenite and ferrite microstructure which provides high tensile strength and excellent resistance to stress corrosion cracking. Such Duplex Steel Bars offer outstanding resistance to corrosion, high level of tolerance and toughness.

ASTM A276 Duplex Steel S32205 Rods Exporter, SAF 2205 Rectangular Bar, ASTM A276 Duplex Stainless Steel S32205 Hex Bar Supplier, Duplex S31803 Square Bar, Duplex Steel S31803 Forged Bar, Duplex ASTM A276 S31803 Flat Bar, Duplex S31803 Bright Bar, Duplex S31803/S32205 Round Bar Manufacturer in India.

Duplex Steel UNS S32205 Rods possess certain silent characteristics such as high chloride stress corrosion cracking resistance, chloride cracking and ease of handling, high strength, good weldability and formability.The chromium, nitrogen and molybdenum content Duplex Steel UNS S31803 Rods are most important for chloride crevice and pitting corrosion resistance. Duplex Steel 2205 Round Bars are not generally suitable for use at temperatures above 300 degrees C as it suffers from precipitation of brittle micro-constituents, nor below -50 degrees C because of its ductile-to-brittle-transition. Duplex Steel Round Bars are hot worked in the temperature range of 954-1149 degrees C (1750-2100degrees F).

Duplex Steel UNS S32205 / S31803 Hex Bar, UNS S31803 Hot Rolled Bar Trader, S31803 Duplex Stainless Steel Polished Round Bar Stockists, SAF 2205 Round Rods, Duplex DIN 1.4462 Flat Bars Dealer, ASTM A276 Duplex S31803 Cold Rolled Round Bars, ASME SA276 Duplex S32205 Round Bar Supplier in India.

Duplex steel Rods show very good pitting and uniform corrosion resistance, high strength and high resistance to stress corrosion cracking (SCC). We supply these round bars and rods to diverse industries including seawater desalination plants, oil & gas equipment, paper & pulp industry, offshore technology, chemical & food processing, fertilizers, sugar mills & distilleries, cement industries, shipbuilding, and petrochemical industry.

We offer various test certificates along with our Duplex Steel Round Bars and Rods the test certificates include Mill Test Certificates, EN 10204 3.1/3.2, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, etc.

| STANDARD | WNR. |

|---|---|

| Duplex S31803 / S32205 | 1.4462 |

Duplex S31803/S32205 Forged Bar

UNS S31803 Forged Bar, Duplex Stainless Steel S31803 Forged Rod, ASTM A276 S31803 Duplex Steel Polish Forged Bar, ASME SA 276 Duplex S32205 Forged Bar

Duplex S31803/S32205 Bright Bar

ASTM A276 S32205 Duplex Steel Bright Bar, Duplex UNS S31803/ S32205 Bright Bar, Duplex S31803 Bright Rod, Duplex S31803/S32205 Polish Bright Bar

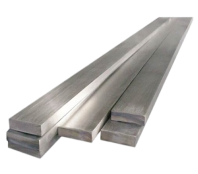

Duplex S31803/S32205 Flat Bar

Duplex Stainless Steel SAF 2205 Flat Bar, UNS S31803 Flat Bar, ASME SA 276 Duplex Steel S31803 Flat Bar, ASTM A276 S32205 Duplex Flat Rod, Duplex S31803/S32205 Polish Flat Bar

Duplex S31803/S32205 Rectangular Bar

Duplex Steel ASTM A276 S31803 Rectangular Bar, UNS S31803 / DIN 1.4462 Rectangular Bar, ASME SA276 Duplex S32205 Rectangular Rod, Duplex S31803 Rectangle Rod, Stainless S31803 Rectangle Bar, Polish Duplex S32205 Rectangular Bar Supplier

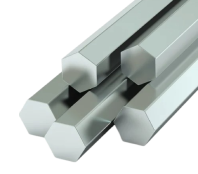

Duplex S31803/S32205 Hex Bar

ASME SA276 Duplex S31803 / S32205 Hex Bar, ASTM A276 Duplex Steel S31803 Hex Bar, Duplex SAF 2205 Hex Bar, UNS S31803 Hex Bar, Duplex S31803 / S32205 Hex Rod, Duplex S31803 Polish Hex Bar, Duplex S31803/S32205 Hex Rod

Duplex S31803/S32205 Square Bar

Duplex Steel S31803 Square Bar, UNS S31803 / S32205 Square Bar, DIN 1.4462 Square Rod, ASME SA 276 Duplex S32205 Square Bar, Duplex Stainless Steel S31803 Polish Square Bar, Duplex S31803/S32205 Square Rod

Duplex Steel Round Bar Specification :

ASTM A276 / A479, ASME SA276 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Size :

14mm-300mm

Length :

1 To 6 Meters, Custom Cut Length

Form :

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Thickness :

0.3 mm to 120 mm

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

| Grade | Common Name | C% | Mn% | Si% | P% | S% | Cr% | Ni% | Mo% | N% |

|---|---|---|---|---|---|---|---|---|---|---|

| 2205 | S31803 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

| 2205 | S32205 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 |

| Tensile strength | 620MPa min | Density | 7,805kg/m3 |

|---|---|---|---|

| Yield strength | 450MPa mi | Elastic modulus | 200GPa |

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)-°F |

Thermal Conductivity BTU/hr-ft-°F | Specific Heat BTU/lbm -°F | Modules of Elasticity (annealed)2-psi | |

|---|---|---|---|---|---|

| at 68 °F | at 68 – 212°F | at 68 – 1832°F | at 200°F | at 32 – 212°F | in tension (E) |

| 0.286 | 9.2 | 20.5 | 9.3 | 0.12 | 28 x 106 |

Our Duplex Steel Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry