Cupro Nickel Forged Fittings Specification :

ASTM B467 / ASME SB467

Cupro Nickel Forged Fittings Specification :

ASTM B467 / ASME SB467

Dimension Standard :

ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799

Size :

1/8" NB to 4" NB

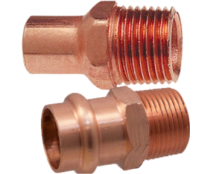

Type :

Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

In industries where seawater, pressure, and corrosion meet every day, material choice is not optional—it’s critical. Copper Nickel 90/10 Forged Fittings are engineered precisely for such demanding environments, offering a rare combination of strength, longevity, and natural resistance to marine degradation. Across the Gulf, these fittings play a silent but essential role in keeping systems reliable and compliant.

What Makes Copper Nickel 90/10 Unique?

Copper Nickel 90/10 is an alloy containing approximately 90% copper and 10% nickel, enhanced with small additions of iron and manganese. This composition gives it exceptional resistance to seawater corrosion, erosion, and biofouling—problems that commonly affect carbon steel and even stainless steel in marine conditions.

Unlike cast components, forged fittings are shaped under controlled pressure, resulting in a refined grain structure, higher mechanical strength, and superior pressure integrity.

Forged Fitting Range & Configurations : Our portfolio of Copper Nickel 90/10 Forged Fittings is designed to meet diverse piping layouts and pressure requirements:

Available as copper nickel 90/10 socket weld fittings and copper nickel 90/10 threaded fittings, including cu-ni 90/10 threaded forged fittings NPT, these products align with ASME B16.11 and related international standards.

Sizes, Pressure Classes & Material Standards: To suit high-pressure and compact piping systems, Copper Nickel 90/10 Forged Fittings are commonly supplied in:

All fittings are manufactured from UNS C70600 forged fittings, ensuring consistent chemical composition and mechanical reliability.

Why Use Copper Nickel 90/10 in Seawater Piping?

Engineers consistently specify Copper Nickel 90/10 because it naturally forms a protective oxide layer when exposed to seawater. This layer prevents pitting, limits erosion, and delivers strong anti biofouling copper nickel fittings performance—without relying on coatings.

That is why Copper Nickel 90/10 Forged Fittings are widely used in: Shipbuilding cu-ni 90/10 pipe fittings, Condenser line copper nickel 90/10 fittings, Firewater system copper nickel 90/10 fittings and Desalination and offshore seawater circuits.

Gulf-Focused Supply & Availability

As a trusted 90/10 cupro nickel forged fittings supplier, we support project and maintenance needs across key industrial hubs:

Buyers frequently inquire about copper nickel 90/10 forged fittings price UAE and copper nickel 90/10 fittings price Saudi, especially for fast-track marine and energy projects. Pricing depends on size, class, connection type, and volume.

| STANDARD | UNS | WNR. | EN | AFNOR |

|---|---|---|---|---|

| Cupro Nickel 90/10 | C70600 | 2.0872 | NiCr20CuMo | Z2NCUD31-20AZ |

Cupro Nickel 90/10 Socket Weld Elbow

Cupro Nickel 90/10 Forged Elbow, UNS C70600 Threaded Elbow, DIN 2.0872 Forged Elbow, ASME SB467 Cupro Nickel Alloy 90/10 45 deg Threaded Elbow, Cupro Nickel 90/10 90 deg Forged Elbow

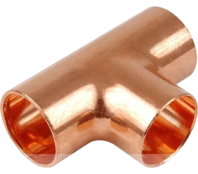

Cupro Nickel 90/10 Forged Tee

ASME SB467 Copper Nickel 90/10 Socket Weld Tee, ASTM B467 Cupro Nickel 90/10 Forged Equal Tee, DIN 2.0872 Reducing Tee, UNS C70600 Unequal Tee, Nickel® 90 / 10 Reducing Tee, Cu-Ni Alloy 90/10 Threaded Equal Tee

Cupro Nickel 90/10 Forged Cross

Cupro Nickel® Alloy 90/10 Threaded Equal Cross, UNS C70600 / DIN 2.0872 Forged Cross, Cu-Ni Alloy 90/10 Socketweld Equal Cross, Cupro Nickel 90/10 Threaded Cross, Copper Nickel Alloy 90/10 Reducing Cross, Copper Nickel Alloy 90/10 Forged Unequal Cross

Alloy 90/10 Full Coupling

DIN 2.0872 Threaded Full Coupling, UNS C70600 Forged Full Coupling, ASME SB467 Copper Nickel 90/10 Socketweld Full Coupling, ASTM B467 Cupro Nickel Alloy 90 / 10 Full Coupling

Cupro Nickel 90/10 Forged Half Coupling

ASTM B467 90/10 Cupro Nickel Socket Weld Half Coupling, Alloy UNS C70600 Half Coupling, ANSI B16.11 Cupro Nickel 90/10 Threaded Half Coupling

Cupro Nickel 90/10 Forged Pipe Cap

UNS C70600 Forged Pipe End Cap, Cupro Nickel 90/10 Threaded Pipe Cap, ASTM B467 Cupro Nickel® 90/10 Socketweld Pipe Cap, ASME SB467 Copper Nickel Alloy 90/10 Forged Pipe End Cap

Cupro Nickel Alloy 90/10 Forged Union

UNS C70600 Socketweld Union, ANSI B16.5 Cupro Nickel 90/10 Union, ASTM B467 Cu-Ni Alloy 90/10 Threaded Union, ASME SB 467 Cupro Nickel® 90 / 10 Forged Union

Cupro Nickel 90/10 Forged Bushing

UNS C70600 Bushing, B16.36 Cupro Nickel 90/10 Hex Head Bushing, ASTM B467 Cupro Nickel 90/10 Threaded Bushing, ASME SB 467 Cupro Nickel Alloy 90 / 10 Forged Threaded Bushing

Cupro Nickel 90/10 Forged Nipple

UNS C70600 Threaded Nipple, B16.36 Cupro Nickel Alloy 90/10 Socketweld Nipple ASTM B467 Copper Nickel 90/10 Swage Nipple, ASME SB467 Cupro Nickel Alloy 90/10 Hex Nipple, Copper Nickel® 90/10 Screwed Pipe Nipple

Cupro Nickel Forged Fittings Specification :

ASTM B467 / ASME SB467

Dimension Standard :

ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799

Size :

1/8" NB to 4" NB

Type :

Socketweld Fittings, Screwed-Threaded Fittings (NPT or PT Type)

Rating Pressure :

Threaded End - 2000 /3000/ 6000 LBS. Socket-weld End - 3000 / 6000/ 9000 LBS.

Chemical Composition of Cupro Nickel 90/10 Forged Fittings

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

|---|---|---|---|---|---|---|

| Cupro Nickel 90/10 | 88.6 | 1.0 max | 0.05 max | 9 - 11 max | 1.8 max | 1 max |

Mechanical Properties Of Cupro Nickel 90/10 Forged Fittings

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Physical Properties of 90/10 Cupro Nickel Forged Fittings

| Density (Kg.m-1) | 84.3 |

|---|---|

| Magnetic Permeability (20°C) | <1.005 |

| Curie Temperature (°C) | -90 |

| Young’s Modulus (N/mm2) | 179 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 418 |

| Specific Electrical Resistance, 20°C (?O.m) | 0.62 |

| Thermal conductivity,20°C (W.m-1.°K-1) | 17.5 |

| Mean coefficient of thermal expansion, 20-100°C (°K-1) | 13.4 x 10-6 |

Our Copper Nickel 90/10 Forged Fittings are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry