Cupro Nickel Flanges Specification :

ASTM B151 / ASME SB151

Cupro Nickel Flanges Specification :

ASTM B151 / ASME SB151

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Copper Nickel 90/10 flanges are manufactured from an alloy comprising 90% copper and 10% nickel, with trace additions of elements such as iron and manganese to enhance strength and corrosion resistance. This alloy is renowned for its exceptional resistance to seawater corrosion, particularly in environments where biofouling, high salinity, and turbulence are present. The protective oxide layer that naturally forms on its surface contributes to its longevity, allowing the material to self-heal in the presence of oxygen, thereby extending its functional life even in harsh marine and industrial conditions. The alloy’s thermal conductivity and low expansion coefficient further make it suitable for systems exposed to fluctuating temperatures.

Available in a range of types—including weld neck, slip-on, blind, socket weld, lap joint, and threaded—Copper Nickel 90/10 flanges are designed to meet rigorous international specifications such as ASTM B151, B122, and ASME B16.5, ensuring global compatibility in high-pressure piping systems. The alloy displays excellent weldability and workability, supporting ease of fabrication without compromising material integrity. With a tensile strength typically ranging from 275 to 310 MPa and a yield strength between 105 and 135 MPa, this alloy delivers dependable performance in applications that demand moderate pressure handling along with strong resistance to fatigue and stress-related cracking.

In terms of metallurgical behavior, the 90/10 composition delivers superior resistance to hydrogen embrittlement and ammonia stress corrosion cracking, which are critical concerns in petrochemical and offshore applications. The alloy also demonstrates stable performance in acidic and alkaline environments, making it versatile across varied chemical process conditions. Its non-magnetic nature and resistance to spark formation enhance safety in electrically sensitive or potentially explosive environments. The combination of these attributes ensures Copper Nickel 90/10 flanges remain a preferred material for long-lasting, low-maintenance pipeline connections.

Applications

Copper Nickel 90/10 flanges serve a broad range of applications that demand durability, corrosion resistance, and thermal efficiency. In marine engineering, these flanges are integral to seawater cooling, bilge, ballast, firefighting, and bilge systems, as well as in the construction of hull-mounted piping and underwater fittings. Their resistance to marine growth and biological fouling ensures uninterrupted operation in shipboard and offshore systems, reducing downtime and maintenance intervals significantly. The alloy’s excellent heat transfer capabilities make it highly effective in heat exchangers, condensers, and evaporators in both naval and commercial marine vessels.

In the power generation sector, 90/10 Copper Nickel flanges are used in cooling water systems, feedwater heaters, and auxiliary piping in nuclear and thermal power plants. Their performance in high-humidity and chemically aggressive conditions makes them suitable for extended service in closed and open-loop cooling circuits. Additionally, they are often deployed in district heating systems and gas scrubbing units, where stability against erosion and pressure fluctuations is critical. Their compatibility with various joining methods, including brazing, welding, and soldering, supports flexible installation in both new construction and retrofitting projects.

Furthermore, the alloy’s compatibility with desalinated and brackish water applications expands its utility in water treatment plants and desalination facilities. Copper Nickel 90/10 flanges are also utilized in chemical processing industries where exposure to acidic gases or saline effluents is common. HVAC systems, offshore platforms, fire suppression pipelines, and industrial refrigeration units all benefit from the alloy’s ability to withstand thermal shocks, corrosion, and mechanical stresses. Their high thermal stability also makes them ideal for use in cryogenic and high-temperature process lines, ensuring consistent performance across a wide range of operational scenarios.

Industry Use

Industries across the Middle East and South Asia increasingly rely on Copper Nickel 90/10 flanges to support mission-critical infrastructure exposed to aggressive environments. In countries such as the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq, these flanges are essential components in offshore oil and gas exploration, refining operations, and petrochemical distribution networks. Their ability to perform reliably in subsea and coastal installations, where saline conditions and chemical exposure are continuous, makes them indispensable to regional energy projects. In India, they are widely used in coastal power plants, shipbuilding yards, and heavy engineering units involved in fluid transfer technologies.

The 90/10 copper-nickel alloy flanges are widely utilized in the marine and shipbuilding sectors for assembling critical components in cargo carriers, naval ships, offshore tankers, and subsea machinery to their outstanding durability in saline environments and dependable mechanical strength. Their capacity to resist erosion and corrosion from high-velocity seawater and their excellent biofouling resistance significantly reduce lifecycle costs for maritime operators. As Gulf countries continue to invest in maritime logistics and strengthen their naval capabilities, the need for robust, corrosion-resistant piping solutions is on the rise—making Copper Nickel 90/10 a vital material for advancing regional infrastructure in coastal and offshore environments.

In environmental and water resource sectors, particularly in desalination and wastewater treatment plants, the flanges support critical operations that demand corrosion-resistant and long-lasting components. These systems often handle aggressive media, and any failure in connections can lead to service disruption or safety hazards. The long service life, recyclability, and minimal maintenance requirements of Copper Nickel 90/10 flanges align well with modern sustainability goals. As industries evolve to prioritize energy efficiency and environmental compliance, the demand for technically advanced and eco-friendly piping materials such as these flanges continues to rise across India and the Gulf Cooperation Council (GCC) countries.

| STANDARD | UNS | WNR. | EN | AFNOR |

|---|---|---|---|---|

| Cupro Nickel 90/10 | C70600 | 2.0872 | NiCr20CuMo | Z2NCUD31-20AZ |

Cupro Nickel 90/10 Slip On Flanges

Copper Nickel 90/10 SORF Flanges, UNS C70600 Slip On Flanges, DIN 2.0872 SORF Flanges, ASME SB 151 Cu-Ni 90/10 Slip-on Raised Face Flanges

Cupro Nickel 90/10 Weld Neck Flanges

ASME SB151 Cupro Nickel 90/10 WNRF Flanges, ASTM B151 Cu-Ni 90/10 Weld Neck Flanges, DIN 2.0872 Weld Neck Flanges, UNS C70600 Weld Neck Raised Face Flanges

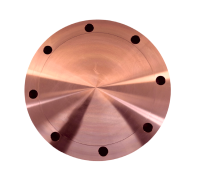

Cupro Nickel 90-10 Blind Flanges

ASTM B151 Cu-Ni 90/10 Blind Flanges, UNS C70600 / DIN 2.0872 Blind Flanges, ASME SB151 Cupro Nickel 90/10 BLRF Flanges, Copper Nickel 90/10 Blind Raised Face Flanges Supplier

Cupro Nickel 90/10 Threaded Flanges

DIN 2.0872 Threaded Flanges, UNS C70600 Screwed Flanges, ASME SB 151 Copper Nickel 90/10 Threaded Flanges, ASTM B151 Cu-Ni 90/10 Threaded Flanges

Cupro Nickel 90/10 Socket Weld Flanges

ASTM B151 Copper Nickel 90/10 Socket Weld Flanges, Cupro Nickel UNS C70600 Socket Weld Flanges, Copper Nickel DIN 2.0872 Socket Weld Flanges

Cupro Nickel 90/10 Lap Joint Flanges

UNS C70600 Lap Joint Flanges, Copper Nickel 90/10 Lap Joint Flanges, ASTM B151 Cu-Ni 90/10 Lap Joint Flanges, ASME SB151 CuNi 90/10 Lap Joint Flanges

Copper Nickel 90/10 Ring Type Joint Flange

UNS C70600 Ring Type Joint Flange, ANSI B16.9 Cu-Ni 90-10 RTJ Flanges, ASTM B151 Cupro Nickel 90/10 Ring Type Joint Flanges, ASME SB151 Copper Nickel 90/10 Ring Type Joint Flanges

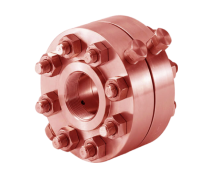

Cupro Nickel 90/10 Orifice Flanges

UNS C70600 Orifice Flanges, B16.36 Copper Nickel 90/10 Orifice Flanges, ASTM B151 Cu-Ni 90-10 Orifice Flanges, ASME SB 151 Cupro Nickel 90/10 Orifice Flanges

Cupro Nickel 90/10 Long Weld Neck Flanges

UNS C70600 Long Weld Neck Flanges, Copper Nickel Alloy 2.0872 Long Weld Neck Flanges, ASTM B151 Cupro Nickel 90/10 Long Weld Neck Flanges, ASME SB 151 Cu-Ni 90/10 Long Weld Neck Flanges

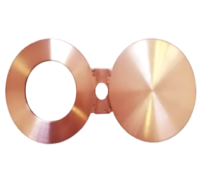

Cupro Nickel 90/10 Spectacle Blind Flanges

UNS C70600 Spectacle Blind Flanges, ANSI / ASME B16.9 Cu-Ni 90/10 Spectacle Blind Flanges, ASTM B151 CuNi 90-10 Spectacle Blind Flanges

Cu-Ni 90/10 Forged Flanges

UNS C70600 Forged Flanges, B16.9 Copper Nickel Alloy 90/10 Forged Flanges, ASTM B151 Cupro Nickel 90/10 Forged Flanges, ASME SB151 Cupro Nickel 90/10 Forged Flanges

Cupro Nickel 90/10 Plate Flanges

UNS C70600 Plate Flanges, ANSI B16.9 Cu-Ni 90-10 Plate Flanges, ASTM B151 Cupro Nickel 90/10 Plate Flanges, ASME SB151 Copper Nickel 90/10 Plate Flanges

Cupro Nickel Flanges Specification :

ASTM B151 / ASME SB151

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Cupro Nickel 90/10 Flanges

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

|---|---|---|---|---|---|---|

| Cupro Nickel 90/10 | 88.6 | 1.0 max | 0.05 max | 9 - 11 max | 1.8 max | 1 max |

Mechanical Properties Of Cupro Nickel 90/10 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Our Copper Nickel 90 / 10 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry