Cupro Nickel Flanges Specification :

ASTM B151 / ASME SB151

Cupro Nickel Flanges Specification :

ASTM B151 / ASME SB151

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Crafted from a high-performance alloy containing 70% copper and 30% nickel, these flanges are further strengthened with small amounts of iron and manganese, which contribute to their exceptional corrosion resistance and mechanical durability. This metallurgical configuration provides exceptional resistance to seawater corrosion, biofouling, and stress corrosion cracking, making it particularly suitable for aggressive marine environments. The flanges offer robust performance in saline and brackish water applications due to the formation of a protective oxide film on the surface, which self-heals in the presence of oxygen. Additionally, Copper Nickel 70/30 exhibits superior thermal stability, excellent tensile strength, and low magnetic permeability, further adding to its utility in complex fluid handling systems.

From a manufacturing standpoint, Copper Nickel 70/30 flanges are available in various types including weld neck, slip-on, socket weld, blind, threaded, and lap joint flanges. These are produced in conformity with international standards such as ASME, ASTM, DIN, and EN specifications, ensuring compatibility across global infrastructure projects. The alloy offers good machinability and weldability, with a consistent grain structure that supports precision fabrication and long-term operational reliability. Its mechanical properties—such as a tensile strength of approximately 320 MPa and a yield strength of 125 MPa—allow it to maintain structural integrity under moderate pressure and temperature variations, which is critical for both onshore and offshore installations.

The flanges are also known for their excellent resistance to erosion and cavitation, particularly in high-velocity seawater systems. This makes them a preferred choice in applications involving fluctuating flow dynamics. With a melting point of around 1170°C and excellent creep resistance, 70/30 Copper Nickel flanges deliver reliable performance in thermally demanding environments. Their lifecycle durability reduces the need for frequent replacements, making them a cost-effective solution in terms of total ownership cost. The combination of metallurgical precision and application resilience positions these flanges as a technically superior choice for mission-critical systems in harsh environments.

Applications

Copper Nickel 70/30 flanges are widely utilized in environments where resistance to seawater and bio-corrosive agents is paramount. Their primary application lies in marine and naval engineering, where they are used in seawater piping systems, desalination plants, bilge and ballast systems, firewater systems, and heat exchangers. The alloy’s ability to resist microbial-induced corrosion (MIC) and scaling makes it ideal for use in environments where continuous contact with seawater or brine is unavoidable. These flanges are also extensively used in shipbuilding, particularly in the construction of underwater piping, cooling systems, and propulsion components where longevity and performance are crucial.

In the energy and power generation sector, Copper Nickel 70/30 flanges play a vital role in cooling water systems of thermal and nuclear power plants. They are used in condenser tubing, feedwater heaters, and auxiliary cooling circuits where their resistance to high-temperature oxidation and erosion enhances system reliability. Chemical processing units also benefit from the alloy’s resistance to acidic and alkaline solutions, particularly in areas where conventional stainless steel might corrode prematurely. Their application extends to HVAC systems, offshore platforms, and fire suppression systems, where safety and durability are non-negotiable.

Moreover, these flanges are integral to offshore oil and gas operations, where extreme operating conditions demand materials that can endure fluctuating pressure, salinity, and chemical exposure. The non-magnetic and spark-resistant nature of Copper Nickel 70/30 makes it an ideal material for precision applications such as instrumentation systems, control mechanisms, and fluid flow regulation in sensitive operational environments. They are also increasingly employed in renewable energy projects, such as ocean thermal energy conversion (OTEC) systems and floating solar platforms, where exposure to marine conditions is constant. The versatility of these flanges across such a wide spectrum of applications is a testament to their engineering excellence and material robustness.

Industry Use

Industries operating in coastal, offshore, and industrial environments rely heavily on Copper Nickel 70/30 flanges for their unmatched durability and corrosion resistance. In the maritime and shipbuilding industries, these flanges have become indispensable for constructing critical fluid systems that must perform reliably over long durations with minimal maintenance. Their widespread adoption in naval fleets, commercial vessels, and cargo ships underscores their strategic importance in enhancing operational uptime and safety in oceanic transportation.

In the oil and gas industry as especially across major energy-producing regions such as the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, Oman, Iran, and Iraq that Flanges made from the 70/30 copper-nickel alloy are widely favored in both upstream extraction and downstream processing activities due to their durability and resistance to harsh operating conditions. These countries, along with India, also utilize these flanges in refinery cooling systems, offshore extraction units, petrochemical pipelines, and LNG terminals, where exposure to saline water and harsh chemicals can compromise less durable materials. The ability of this alloy to function seamlessly under such aggressive conditions reduces system downtime and boosts asset longevity, thus supporting operational efficiency.

In infrastructure development and utility services, especially within desalination plants and water treatment facilities across the Middle East and South Asia, the reliability of Copper Nickel 70/30 flanges is pivotal. These regions prioritize water infrastructure resilience due to climatic conditions, and the alloy’s performance has been proven in thousands of installations. The increasing demand for long-lasting materials in environmentally sensitive and mission-critical operations continues to drive the adoption of these flanges in both public and private sector projects. With growing emphasis on sustainable engineering practices, the long service life, ease of maintenance, and recyclability of Copper Nickel 70/30 flanges make them a preferred choice for environmentally responsible infrastructure and industrial applications.

| STANDARD | UNS | WNR. | EN | AFNOR |

|---|---|---|---|---|

| Cupro Nickel 70/30 | C71500 | 2.0882 | NiCr20CuMo | Z2NCUD31-20AZ |

Cupro Nickel 70/30 Slip On Flanges

Copper Nickel 70/30 SORF Flanges, UNS C71500 Slip On Flanges, DIN 2.0882 SORF Flanges, ASME SB 151 Cu-Ni 70/30 Slip-on Raised Face Flanges

Cupro Nickel 70/30 Weld Neck Flanges

ASME SB151 Cupro Nickel 70/30 WNRF Flanges, ASTM B151 Cu-Ni 70/30 Weld Neck Flanges, DIN 2.0882 Weld Neck Flanges, UNS C71500 Weld Neck Raised Face Flanges

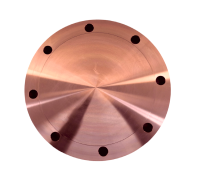

Cupro Nickel 70-30 Blind Flanges

ASTM B151 Cu-Ni 70/30 Blind Flanges, UNS C71500 / DIN 2.0882 Blind Flanges, ASME SB151 Cupro Nickel 70/30 BLRF Flanges, Copper Nickel 70/30 Blind Raised Face Flanges Supplier

Cupro Nickel 70/30 Threaded Flanges

DIN 2.0882 Threaded Flanges, UNS C71500 Screwed Flanges, ASME SB 151 Copper Nickel 70/30 Threaded Flanges, ASTM B151 Cu-Ni 70/30 Threaded Flanges

Cupro Nickel 70/30 Socket Weld Flanges

ASTM B151 Copper Nickel 70/30 Socket Weld Flanges, Cupro Nickel UNS C71500 Socket Weld Flanges, Copper Nickel DIN 2.0882 Socket Weld Flanges

Cupro Nickel 70/30 Lap Joint Flanges

UNS C71500 Lap Joint Flanges, Copper Nickel 70/30 Lap Joint Flanges, ASTM B151 Cu-Ni 70/30 Lap Joint Flanges, ASME SB151 CuNi 70/30 Lap Joint Flanges

Copper Nickel 70/30 Ring Type Joint Flange

UNS C71500 Ring Type Joint Flange, ANSI B16.9 Cu-Ni 70-30 RTJ Flanges, ASTM B151 Cupro Nickel 70/30 Ring Type Joint Flanges, ASME SB151 Copper Nickel 70/30 Ring Type Joint Flanges

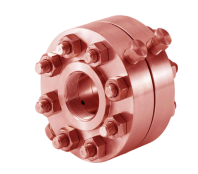

Cupro Nickel 70/30 Orifice Flanges

UNS C71500 Orifice Flanges, B16.36 Copper Nickel 70/30 Orifice Flanges, ASTM B151 Cu-Ni 70-30 Orifice Flanges, ASME SB 151 Cupro Nickel 70/30 Orifice Flanges

Cupro Nickel 70/30 Long Weld Neck Flanges

UNS C71500 Long Weld Neck Flanges, Copper Nickel Alloy 2.0882 Long Weld Neck Flanges, ASTM B151 Cupro Nickel 70/30 Long Weld Neck Flanges, ASME SB 151 Cu-Ni 70/30 Long Weld Neck Flanges

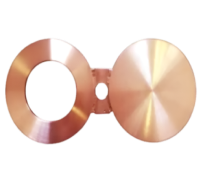

Cupro Nickel 70/30 Spectacle Blind Flanges

UNS C71500 Spectacle Blind Flanges, ANSI / ASME B16.9 Cupro Nickel 70/30 Spectacle Blind Flanges, ASTM B151 CuNi 70-30 Spectacle Blind Flanges

Cu-Ni 70/30 Forged Flanges

UNS C71500 Forged Flanges, B16.9 Copper Nickel Alloy 70/30 Forged Flanges, ASTM B151 Cupro Nickel 70/30 Forged Flanges, ASME SB151 Cupro Nickel 70/30 Forged Flanges

Cupro Nickel 70/30 Plate Flanges

UNS C71500 Plate Flanges, ANSI B16.9 Cu-Ni 70-30 Plate Flanges, ASTM B151 Cupro Nickel 70/30 Plate Flanges, ASME SB151 Copper Nickel 70/30 Plate Flanges

Cupro Nickel Flanges Specification :

ASTM B151 / ASME SB151

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Cupro Nickel 70/30 Flanges

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

|---|---|---|---|---|---|---|

| Cupro Nickel 70/30 | 65 min | 1.0 max | 0.05 max | 29-33 max | 0.4-1.0 max | 1 max |

Mechanical Properties Of Cupro Nickel 70/30 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Our Copper Nickel 70 / 30 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry