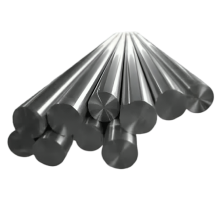

Tantalum Round Bar Specification :

ASTM B365 / A479, ASME SB365 / A479

Tantalum Round Bar Specification :

ASTM B365 / A479, ASME SB365 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Width :

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :

1 To 6 Meters, Custom Cut Length

Finding the right tantalum round bar in Mumbai is not always easy. Buyers in chemical processing, aerospace, laboratory research, and high-temperature manufacturing need a material that can survive extreme conditions without corrosion, deformation, or contamination. That’s exactly why industries across Andheri, Navi Mumbai, Thane, Bhiwandi, and Taloja rely on certified tantalum metal bars for demanding projects.

What Makes Tantalum Round Bar a Preferred Choice?

Tantalum is one of the most corrosion-resistant refractory metals in the world. It withstands high temperatures, strong acids, and aggressive chemicals, making it a top choice for:

Many Mumbai buyers specifically look for material purity like 99.95% pure tantalum rods, RO5200 / RO5400 grades, and diameters ranging from 3mm up to 100mm.

High-Purity • High Strength • Long Lifespan

Whether you’re searching for high-purity tantalum bars in Mumbai, checking the tantalum rod rate per kg in India, or comparing tantalum bar cost among the cheapest suppliers in the region—one fact stays the same: real industrial-grade tantalum offers unmatched durability and value.

And for buyers in chemical line production, reactors, or aerospace tooling, nothing works better as an alternative to titanium or nickel alloys in extreme environments.

Serving All Major Industrial Zones in Mumbai

Industries across the city depend on quick access to ready stock, especially in:

Whether you need custom-cut tantalum rods, precision-machined tantalum bars, or want to buy bar and rod in Mumbai with quick delivery, premium suppliers in these zones offer tailored fulfilment.

Available Sizes & Customization

Most buyers look for stock like:

If your requirement involves precision machining or a specific size that isn't available off the shelf, Mumbai’s better-known suppliers offer custom fabrication based on your drawing or specification.

Tantalum Rod Price in Mumbai — What Affects the Cost?

This metal rod price in Mumbai depends on:

Buyers often compare wholesale rates, evaluate cost differences between suppliers, and look for certified refractory metal bar distributors in Mumbai to get better value.

Why Mumbai Buyers Prefer Certified Tantalum Suppliers

✔ Ready stock availability

✔ MTC (Mill Test Certificate)

✔ Chemical & mechanical property reports

✔ Consistent grade quality

✔ Fast delivery across industrial zones

A trusted supplier ensures you’re not just getting a bar of metal—you’re getting verified, traceable, tested designed for critical environments.

Looking for Tantalum Round Bar in Mumbai? Here’s What to Do Next

If you're looking to buy tantalum bars in Mumbai, evaluate the following before placing your order:

Whether you’re sourcing for aerospace needs, chemical reactors, lab equipment, or high-temperature fabrication, choosing a certified distributor like KVN that ensures performance, durability, and complete material traceability.

Tantalum Alloy R05200 Square Bar

R05200 Square Bar, UNS R05200 / R05400 Square Bar, R05200 Square Rod, ASME SB 365 Alloy RO5400 Square Bar, R05200/R05400 Tantalum Polish Square Bar, Tantalum R05200/R05400 Square Rod

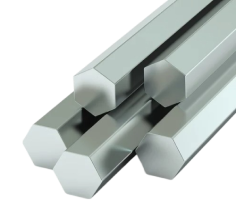

Tantalum R05200/R05400 Hex Bar

ASME SB365 R05200/R05400 Hex Bar, ASTM B365 R05200 Hex Bar, Alloy R05200/R05400 Hex Bar, UNS R05200 Hex Bar, Tantalum R05200/R05400 Hex Rod, Duplex R05400 Polish Hex Bar, Ta Alloy R05200/R05400 Hex Rod

Tantalum R05200 Rectangular Bar

ASTM B365 R05200 Rectangular Bar, UNS R05400 Rectangular Bar, ASME SB365 R05200/R05400 Rectangular Rod, Tantalum R05200 Rectangle Rod, Tantalum R05400 Rectangle Bar

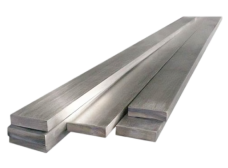

Tantalum R05200/R05400 Flat Bar

Alloy R05200/R05400 Flat Bar, UNS R05200 Flat Bar, ASME SB 365 R05200/R05400 Flat Bar, ASTM B365 R05400 Duplex Flat Rod, Tantalum R05200/R05400 Polish Flat Bar

Tantalum R05200 Bright Bar

ASTM B365 R05200 Tantalum Bright Bar, UNS R05200/R05400 Bright Bar, R05200/R05400 Bright Rod, R05200/R05400 Polish Bright Bar

Tantalum R05200/R05400 Forged Bar

UNS R05200 Forged Bar, R05200/R05400 Forged Rod, ASTM B365 R05200/R05400 Polish Forged Bar, ASME SB 365 Tantalum Alloy R05200/R05400 Forged Bar

Tantalum Round Bar Specification :

ASTM B365 / A479, ASME SB365 / A479

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Width :

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :

1 To 6 Meters, Custom Cut Length

Form :

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc.

| Tantalum | C | O | N | H | Nb | Fe | Ti | W | Mo | Si | Ni | Ta |

| R05200 | 0.010 | 0.015 | 0.010 | 0.0015 | 0.100 | 0.010 | 0.010 | 0.050 | 0.020 | 0.005 | 0.010 | Remainder |

| Tantalum Alloy Rods & Bars Mechanical Property | ||||

| Grade | Tensile strength " , psi (MPa), ≥ | Yield strength " , psi (MPa), ≥ | Elongation in 1 inch gage length, %, ≥ | |

| RO5400 | 25000 (172) | 15000 (103) | 25 | |

| Denstiy lbm/in3 |

Coefficient of Thermal Expansion (min/in)- F |

Thermal Conductivity BTU/hr-ft- F | Specific Heat BTU/lbm - F | Modules of Elasticity (annealed)2-psi | |

|---|---|---|---|---|---|

| at 68 F | at 68 – 212 F | at 68 – 1832 F | at 200 F | at 32 – 212 F | in tension (E) |

| 0.286 | 9.2 | 20.5 | 9.3 | 0.12 | 28 x 106 |

Our Tantalum Round Bar are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry

Get clear answers to common queries about our steel products, services, and delivery processes.

Mumbai’s chemical, aerospace, and medical sectors choose high-purity tantalum rods because they offer exceptional acid resistance, heat stability, and long operational life. Their ability to handle extreme temperatures makes them far more reliable compared to stainless steel or nickel alloys.

Check for Mill Test Certificates (MTCs), heat numbers, chemical composition reports, and density tolerance. Reputed Mumbai suppliers typically provide complete documentation to ensure the metal meets global standards for purity and performance.

Absolutely. These refractory metal bars are widely used in Mumbai’s chemical plants, labs, and process industries because they resist hydrochloric, sulfuric, and nitric acids even at elevated temperatures—making them one of the most durable materials available.

Most suppliers stock diameters ranging from 3 mm to 100 mm, with options for cut-to-length, machining, polishing, and custom fabrication. This helps meet the diverse requirements of engineering, research, and manufacturing units across Navi Mumbai, Thane, and Mumbai city.

If the required size is in stock, dispatch is usually same day or next day. For custom-machined or special-grade material, lead times generally range between 3–7 working days, depending on complexity and quantity.