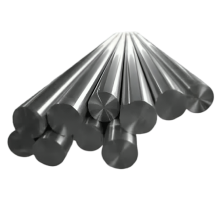

Nickel Round Bar Specification :

ASTM B160, ASME SB160

Nickel Round Bar Specification :

ASTM B160, ASME SB160

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Width :

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Nickel is one of the most sought-after products in industries that demand superior resistance, long-lasting performance, and excellent mechanical strength. These bars are engineered from high-grade nickel alloys that can withstand aggressive chemical environments, extreme heat, and corrosive marine conditions. Known for their outstanding durability and stability, Nickel Alloys Round Bars are widely used in petrochemical plants, marine engineering, chemical processing, oil refineries, and power generation. Their ability to retain strength under both reducing and oxidizing conditions makes them a preferred choice for critical applications where both safety and efficiency are paramount. Backed by precise manufacturing standards and global certifications, these bars are trusted by engineers and project consultants worldwide to deliver reliable and sustainable solutions.

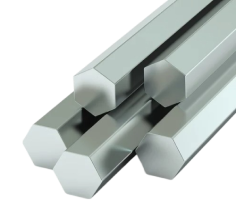

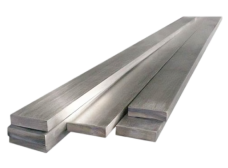

Properties & Industrial Uses of Nickel Alloy Square, Hex, and Rectangular Bars:

Alongside round bar, the market also places high value on specialized options like Nickel Alloy 200/201 Square Bar, which includes both Nickel Alloy 200 Square Bar and Nickel Alloy 201 Square Bar variants. These square bars are particularly recognized for their excellent purity, electrical conductivity, and formability, making them ideal for caustic soda production, food processing, and high-temperature environments. Alloy Square Bar products are engineered to maintain consistent hardness and dimensional accuracy, supporting precision machining and fabrication processes. Moreover, special shapes such as Nickel 201 Hex Bar and Nickel 200 Rectangular Bar extend the versatility of these alloys by catering to industries that demand specific geometric profiles for equipment, structural frameworks, and heavy-duty machinery. Each bar is produced to ensure maximum performance under stress while meeting stringent international standards like ASTM, ASME, and DIN.

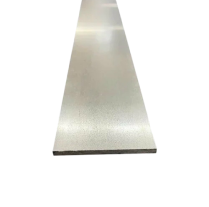

Applications and Benefits of Nickel Alloy Bar:

For projects that demand superior adaptability, industries also rely on advanced product variations including Nickel 201 Flat Bar, Nickel Alloy 200 Bright Bar, and Alloy 200 Forged Bar. These forms are carefully developed to provide smooth surface finishes, enhanced machinability, and the capability to perform consistently in both high-pressure and high-temperature environments. The Nickel Alloy 200 Bright Bar is especially popular for its polished finish, which improves corrosion resistance and ensures a refined look for exposed applications, while the Alloy 200 Forged Bar offers exceptional toughness for high-stress industrial operations. Meanwhile, the Nickel 201 Flat Bar is known for its ability to combine flexibility with structural strength, making it suitable for both fabrication and welding. By offering a comprehensive range of Nickel Alloy bar types, suppliers ensure that industries working in marine, oil & gas, energy, aerospace, and chemical processing have access to tailored solutions that enhance operational efficiency, reduce maintenance costs, and extend the life cycle of equipment.

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| Nickel 200 | N02200 | 2.4066 | NW 2200 | Ni 99.2 |

| Nickel 201 | N02201 | 2.4068 | NW 2201 | LC-Ni 99 |

Nickel Alloy 200/201 Square Bar

Nickel 200 Square Bar, UNS N02200 / N02201 Square Bar, DIN 2.4066 Square Rod, ASME SB 160 Nickel Alloy 201 Square Bar, Nickel 200 Polish Square Bar, Alloy 200/201 Square Rod

Nickel Alloy 200/201 Hex Bar

ASME SB160 Nickel Alloy 200 / 201 Hex Bar, ASTM B160 Nickel 200 Hex Bar, DIN 2.4068 Hex Bar, UNS N02200 Hex Bar, Nickel Alloy 200 / 201 Hex Rod, Nickel Alloy 200 Polish Hex Bar, Nickel Alloy 200/201 Hex Rod

Nickel 200/201 Rectangular Bar

Nickels ASTM B160 200 Rectangular Bar, UNS N02200 / DIN 2.4066 Rectangular Bar, ASME SB160 Nickel Alloy 201 Rectangular Rod, Alloy 200 Rectangle Bar, Polish Nickel Alloy 201 Rectangular Bar Supplier

Nickel Alloy 200/201 Flat Bar

DIN 2.4068 Flat Bar, UNS N02200 Flat Bar, ASME SB 160 Nickel 200 Flat Bar, ASTM B160 201 Nickel Alloy Flat Rod, Nickel® Alloy 200/201 Polish Flat Bar

Nickel Alloy 200/201 Bright Bar

ASTM B160 201 Nickel Bright Bar, Nickel Alloy UNS N02200/ N02201 Bright Bar, Alloy 200 Bright Rod, Nickel Alloy 200/201 Polish Bright Bar

Nickel Alloy 200/201 Forged Bar

UNS N02200 Forged Bar, Nickel 200 Forged Rod, ASTM B160 200 Nickel Polish Forged Bar, ASME SB160 Nickel Alloy 201 Forged Bar

Nickel Round Bar Specification :

ASTM B160, ASME SB160

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Width :

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness :

0.3 mm to 120 mm

Form :

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing :

Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

Chemical Composition of Nickel 200/201 Round Bar

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Of Nickel 200/201 Round Bar

| Grade | Tensile (ksi) | .2% Yield (ksi) | Elongation % | Hardness (HRb) |

|---|---|---|---|---|

| 400 | 75 to 90 | 25 to 50 | 60 to 35 | 60 to 80 |

| K500 | Psi – 1,60,000 , MPa – 1100 | Psi – 1,15,000 , MPa – 790 | 20 % | - |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 | 8.9 g/cm3 | 1446 C (2635 F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Nickel 201 | 8.9 g/cm3 | 1446 C (2635 F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Our Nickel & Nickel Alloys Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry