Nickel Flanges Specification :

ASTM B564 / ASME SB564

Nickel Flanges Specification :

ASTM B564 / ASME SB564

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Nickel 200 flanges are widely used in industries where high purity, corrosion resistance, and thermal stability are essential. Known for their excellent performance in aggressive chemical environments, these flanges are a preferred choice for oil & gas facilities, chemical processing plants, and industrial piping systems across the UAE.

If you are looking to buy Nickel 200 flanges in the UAE, understanding the material, standards, and application suitability is the first step toward making a reliable procurement decision.

What Is a Nickel 200 Flange?

Nickel 200 is a commercially pure nickel alloy (minimum 99.6% Ni), classified under UNS N02200. Flanges manufactured from this alloy offer outstanding resistance to alkalis, caustic solutions, and reducing chemicals, while maintaining mechanical stability over a wide temperature range.

These flanges are commonly produced as per ASTM B564 Nickel 200 specifications, ensuring consistency, durability, and international compliance.

Why Nickel 200 Flanges Are Preferred in the UAE

Industrial projects in the UAE demand materials that can withstand high temperatures, corrosive media, and continuous operation. Nickel 200 flanges and 201 flanges meet these requirements due to:

Because of these properties, Nickel 200 flanges are widely supplied to Dubai, Abu Dhabi, Sharjah, Ajman, and UAE free zones.

Types of Nickel 200 Flanges are Available with KVN Steels

To support diverse piping requirements, Nickel 200 flanges are available in multiple configurations, including:

All variants can be manufactured or supplied in ASME, ANSI, and DIN standards.

Nickel 200 vs Nickel 201 Flanges – What’s the Difference?

While Nickel 200 and Nickel 201 flanges are chemically similar, the key difference lies in carbon content.

Nickel 201 flanges contain lower carbon, making them more suitable for higher temperature applications where carbide precipitation must be avoided.

In practice:

Many UAE projects evaluate both options depending on operating conditions.

Industrial Applications in the UAE

Nickel 200 flanges are widely used in:

Their purity and stability make them suitable for critical operations where material failure is not an option.

Availability, Pricing, and Supply in the UAE

Businesses sourcing from a Nickel 200 flanges supplier in the UAE often prioritize ready stock availability, certification, and competitive pricing. These flanges are supplied through established distributors and stockists serving:

Pricing for Nickel 200 flanges in the UAE depends on size, pressure class, standard, and customization level. Buyers typically request quotes for bulk orders or project-based requirements to optimize cost efficiency.

Flange Standards and Temperature Performance

Nickel 200 flanges conform to global standards such as ASTM B564, ASME, ANSI, and DIN, ensuring compatibility with international piping systems.

They maintain mechanical integrity across a wide temperature range, making them suitable for both ambient and elevated temperature operations.

Choosing the Right Nickel 200 Flange Supplier

When selecting a supplier or distributor in the UAE, it is important to consider:

A knowledgeable supplier like KVN helps ensure long-term performance and operational safety.

Nickel 200 flanges continue to be a trusted solution for demanding industrial environments across the UAE. With multiple flange types, recognized standards, and compatibility alongside Nickel 201 alternatives, they offer flexibility, reliability, and proven performance for modern infrastructure and process industries.

Nickel 200 / 201 Flanges Equivalent Grades

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| Nickel 200 | N02200 | 2.4066 | NW 2200 | Ni 99.2 |

| Nickel 201 | N02201 | 2.4068 | NW 2201 | LC-Ni 99 |

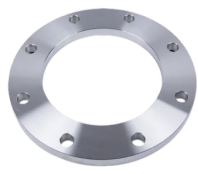

Alloy 200 / 201 Slip On Flanges

Nickel® 200 SORF Flanges, UNS N02200 / N02201 Slip On Flanges, DIN 2.4066 SORF Flanges, ASME SB 564 Alloy 201 Slip-on Raised Face Flanges

Nickel 200 / 201 Weld Neck Flanges

ASME SB564 Nickel 200 WNRF Flanges, ASTM B564 Nickel® 201 Weld Neck Flanges, DIN 2.4066 Weld Neck Flanges, UNS N02200 Weld Neck Raised Face Flanges

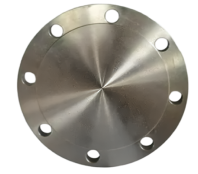

Alloy 200 / 201 Blind Flanges

ASTM B564 Nickel 200 Blind Flanges, UNS N02200 / DIN 2.4066 Blind Flanges, ASME SB564 Alloy 201 BLRF Flanges, Alloy 200/201 Blind Raised Face Flanges Supplier

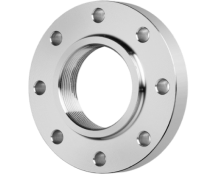

Alloy 200/201 Threaded Flanges

DIN 2.4066 Threaded Flanges, UNS N02200 Screwed Flanges, ASME SB 564 Alloy 201 Threaded Flanges, ASTM B564 Nickel 201 Threaded Flanges

Alloy 200/201 Socket Weld Flanges

ASTM B564 201 Nickel Socket Weld Flanges, Nickel UNS N02200/ N02201 Socket Weld Flanges, Alloy DIN 2.4068 Socket Weld Flanges

Nickel 200/201 Lap Joint Flanges

UNS N02200 Lap Joint Flanges, Nickel® 200 Lap Joint Flanges, ASTM B564 201 Nickel Lap Joint Flanges, ASME SB564 Nickel Alloy 200/201 Lap Joint Flanges

Alloy 200/201 Ring Type Joint Flange

UNS N02200 Ring Type Joint Flange, ANSI B16.5 Nickel 200 RTJ Flanges, ASTM B564 Nickel 201 Ring Type Joint Flanges, ASME SB564 Alloy 200/201 Ring Type Joint Flanges

Nickel 200/201 Orifice Flanges

UNS N02200 Orifice Flanges, B16.36 Nickel 200 / 201 Orifice Flanges, ASTM B564 Alloy 200 Orifice Flanges, ASME SB 564 Nickel Alloy 200/201 Orifice Flanges

Alloy 200/201 Long Weld Neck Flanges

UNS N02201 Long Weld Neck Flanges, Nickel 2.4068 Long Weld Neck Flanges, ASTM B564 Nickel 201 Long Weld Neck Flanges, ASME SB 564 Nickel 201 Long Weld Neck Flanges

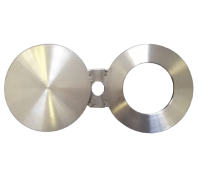

Nickel 200/201 Spectacle Blind Flanges

UNS N02201 Spectacle Blind Flanges, ANSI / ASME B16.5 Alloy 201 Spectacle Blind Flanges, ASTM B564 Alloy 200/201 Spectacle Blind Flanges, ASME SB 564 Nickel 200/201 Spectacle Blind Flanges

Nickel 200/201 Forged Flanges

UNS N02201 Forged Flanges, B16.5 Alloy 200 Forged Flanges, ASTM B564 Nickel Alloy 201 Forged Flanges, ASME SB564 Alloy 200/201 Forged Flanges

Nickel 200/201 Plate Flanges

UNS N02200 Plate Flanges, ANSI B16.5 Nickel 200/201 Plate Flanges, ASTM B564 Nickel 200/201 Plate Flanges, ASME SB564 Nickel Alloy 201 Plate Flanges

Nickel Flanges Specification :

ASTM B564 / ASME SB564

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Nickel 200 / 201 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Properties Of Nickel 200 / 201 Flanges

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nickel 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

Nickel 201 0.02 max 0.35 max 0.35 max 0.01 max 0.25 max 0.40 max 99.0 min

Physical Properties of Nickel 200/201 Flanges

| Density (Kg.m-1) | 84.3 |

|---|---|

| Magnetic Permeability (20°C) | <1.005 |

| Curie Temperature (°C) | -90 |

| Young’s Modulus (N/mm2) | 179 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 418 |

| Specific Electrical Resistance, 20°C (?O.m) | 0.62 |

| Thermal conductivity,20°C (W.m-1.°K-1) | 17.5 |

| Mean coefficient of thermal expansion, 20-100°C (°K-1) | 13.4 x 10-6 |

Our Nickel 200/201 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry

Get clear answers to common queries about our steel products, services, and delivery processes.

When evaluating Nickel 200 flange suppliers in the UAE, buyers should focus on material traceability, compliance with ASTM and ASME standards, and local stock availability. Reputable suppliers provide mill test certificates, dimensional accuracy, and guidance on selecting the right flange type based on pressure, temperature, and chemical exposure. UAE-based stockists also help reduce lead time for urgent industrial projects.

Yes, different flange types serve different operational purposes. Nickel 200 welding neck flanges are commonly selected for high-pressure or high-temperature pipelines. Slip on flanges are preferred where quick alignment and cost efficiency matter, while blind flanges are used to isolate or terminate piping systems. Selecting the right type improves safety, durability, and long-term performance in UAE industrial environments.

Pricing typically depends on size, pressure class, flange type, and standard—such as ANSI, ASME, or DIN. Nickel 200 flange cost in the UAE may also vary based on ready stock availability versus custom manufacturing. Project-scale demand in hydrocarbon and process industries benefits from unit-cost efficiencies when materials are drawn from pre-approved distribution channels with regional stock positioning.

These flanges are valued for their exceptional resistance to alkalis, corrosive chemicals, and reducing environments. Within UAE industrial infrastructure, they are deployed in chemically aggressive and energy-sector systems where metallurgical stability and contamination control are non-negotiable. Their stable performance across varying temperatures makes them suitable for continuous industrial operations with minimal maintenance risk.

UNS N02200 flanges offer excellent corrosion resistance and mechanical stability; however, Nickel 201 variants contain lower carbon content, making them more suitable for elevated temperature applications where carbide precipitation is a concern. Project engineers in the UAE often evaluate both options to ensure long-term performance based on operating temperature and process conditions.