Hastelloy Round Bar Specification :

ASTM B574, ASME SB574

Hastelloy Round Bar Specification :

ASTM B574, ASME SB574

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Width :

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

If you’re searching for Hastelloy round bars in the UAE, chances are you need a material that delivers unmatched corrosion resistance, stability at high temperatures, and long-term performance in harsh industrial environments. From coastal engineering projects to advanced chemical units and major oil operations, companies throughout Dubai, Abu Dhabi, Sharjah, and the wider Gulf region consistently select Hastelloy for its ability to withstand extreme conditions.

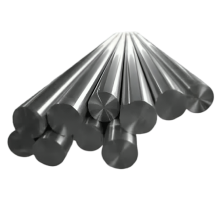

What Are Hastelloy Round Bars?

Hastelloy is a family of nickel-molybdenum and nickel-chromium alloys engineered for extreme corrosion resistance. These Hastelloy round bars are used when standard stainless steel or even superalloys fail—especially in acidic, high-temperature, or chloride-rich environments.

With sizes ranging from 6mm to 300mm, industries in the UAE prefer Hastelloy for its reliability, long service life, and suitability for critical operations.

Why UAE Industries Prefer Hastelloy Round Bars

Exceptional Corrosion Resistance

Whether installed offshore or inside chemical reactors, Hastelloy maintains integrity where other metals degrade.

Heat-Resistant for Extreme Temperatures

Applications in refineries and power plants need alloys that can survive intense heat. Heat-resistant Hastelloy bars UAE is a rising in demand among engineers and procurement teams.

High Strength Across All Conditions

Forged, cold-drawn, and precision-machined Hastelloy bars offer reliable mechanical strength even under heavy loads.

Versatility Across Industries

Hastelloy bars are widely chosen for:

Popular Hastelloy Grades in UAE

Hastelloy C276 Round Bars

Known for excellent resistance to pitting and stress corrosion cracking, Hastelloy C276 round bar UAE is the first choice for aggressive environments.

Hastelloy C22 Round Bars

C22 is preferred for chemical plants and flue-gas cleaning applications.

The market is witnessing increasing demand for the following:

Hastelloy B2, B3 & X Bars

For specialized applications:

Available Forms & Specifications

To meet diverse engineering needs, UAE buyers can choose from:

✔ Forged Hastelloy round bars

Ideal for high-strength requirements.

✔ Cold-drawn Hastelloy bars

Preferred for improved surface finish and tighter tolerances.

✔ Precision-machined Hastelloy bars

Used in aerospace and high-accuracy components.

✔ Custom-size Hastelloy rods UAE

Tailored dimensions for unique project requirements.

Applications Across the UAE Industrial Landscape

Oil & Gas Sector (Onshore & Offshore)

Hastelloy’s resistance to sour gas, chlorides, and high pressure makes it a top choice across ADNOC-linked facilities.

Chemical Processing Plants

From sulfuric to hydrochloric acid environments, Hastelloy rods deliver stability and long operating life.

Marine & Desalination Plants

C276 bars for marine applications UAE remain a trending term for corrosion protection in saline conditions.

Power Plants & High-Heat Equipment

Hastelloy stands strong in thermal cycling and oxidizing atmospheres.

UAE Supply Network – Where Buyers Source Hastelloy Bars

Customers can find reliable availability through:

These regions serve as major distribution points for Hastelloy bar stockists UAE, bar dealers, and bar distributors.

Price Factors – What Affects Hastelloy Bar Cost?

Prices vary based on:

Why Choose Hastelloy Over Inconel?

For environments rich in chlorides, strong acids, or high heat, Hastelloy offers superior resistance compared to many Inconel grades. Engineers finding solutions for Hastelloy vs Inconel bars often select Hastelloy for its reliability in corrosive conditions.

KVN Steels is your trusted source for Hastelloy Round Bars in UAE

Whether you want to buy Hastelloy bars in UAE, compare grades, or check live pricing, choosing the right supplier ensures long-term performance and lower maintenance costs.

| STANDARD | UNS | WNR. | JIS | EN |

|---|---|---|---|---|

| Hastelloy C22 | N06022 | 2.4602 | NW 6022 | NiCr21Mo14W |

| Hastelloy C276 | N10276 | 2.4819 | NW 0276 | NiMo16Cr15W |

Hastelloy Alloy C22/C276 Square Bar

Hastelloy C22 Square Bar, UNS N06022 / N10276 Square Bar, DIN 2.4602 Square Rod, ASME SB 574 Hastelloy Alloy C276 Square Bar, Hastelloy C22 Polish Square Bar, Alloy C22/C276 Square Rod

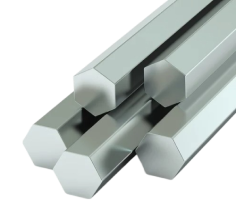

Hastelloy Alloy C22/C276 Hex Bar

ASME SB574 Hastelloy Alloy C22 / C276 Hex Bar, ASTM B574 Hastelloy C22 Hex Bar, DIN 2.4819 Hex Bar, UNS N06022 Hex Bar, Hastelloy Alloy C22 / C276 Hex Rod, Hastelloy Alloy C22 Polish Hex Bar, Hastelloy Alloy C22/C276 Hex Rod

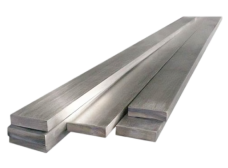

Hastelloy C22/C276 Rectangular Bar

Hastelloys ASTM B574 C22 Rectangular Bar, UNS N06022 / DIN 2.4602 Rectangular Bar, ASME SB574 Hastelloy Alloy C276 Rectangular Rod, Alloy C22 Rectangle Bar, Polish Hastelloy Alloy C276 Rectangular Bar Supplier

Hastelloy Alloy C22/C276 Flat Bar

DIN 2.4819 Flat Bar, UNS N06022 Flat Bar, ASME SB 574 C22 Flat Bar, ASTM B574 C276 Alloy Flat Rod, Hastelloy® Alloy C22/C276 Polish Flat Bar

Hastelloy Alloy C22/C276 Bright Bar

ASTM B574 C276 Bright Bar, Alloy UNS N06022/ N10276 Bright Bar, C22 Bright Rod, Alloy C22/C276 Polish Bright Bar

Hastelloy Alloy C22/C276 Forged Bar

UNS N06022 Forged Bar, C22 Forged Rod, ASTM B574 C22 Polish Forged Bar, ASME SB574 Hastelloy, Alloy C276 Forged Bar

Hastelloy Round Bar Specification :

ASTM B574, ASME SB574

Dimension Standard :

EN, DIN, JIS, ASTM, BS, ASME, AISI

Width :

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness :

0.3 mm to 120 mm

Form :

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Chemical Composition of Hastelloy C22/C276 Round Bar

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C22 | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 max | 20.00 - 22.50 | 2.00 - 6.00 | 12.50 - 14.50 | 0.02 max |

| Hastelloy C276 | 0.01 max | 1.0 max | 0.08 max | 2.50 max | Balance | 14.5-16.5 | 4-7 | 15-17 | 0.04 max | 0.04 max |

Mechanical Properties Of Hastelloy C22/C276 Round Bar

| Grade | Tensile (ksi) | .2% Yield (ksi) | Elongation % | Hardness (HRb) |

|---|---|---|---|---|

| C22 | 115 | 55 | 60 | 89 |

| C276 | 110 | 52.6 | 62 | - |

Physical Properties of 400/K500 Monel Round Bar

| Density@ Room Temp | 0.318 lb/in3 |

|---|---|

| Elastic Modulus @ 70 F (tension) | 26.0 x 106psi |

| Specific Heat @ 70 F | 0.102 Btu/lb/ F |

| Melting Point | 2370 F to 2460 F |

| Thermal Conductivity @ 70 F | 151 Btu in/h/ft 2 / F |

| Electrical Resistivity @ 70 F | 0.511 μ Ω m |

Our Hastelloy Round Bars are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry

Get clear answers to common queries about our steel products, services, and delivery processes.

Most buyers in the UAE—especially in Dubai, Abu Dhabi, and Sharjah—look for suppliers who can provide certified Hastelloy alloys in multiple grades like C276, C22, B2, and X. A reliable supplier will maintain ready stock, offer size options from 6mm to 300mm, share technical test reports, and provide pricing based on current nickel market trends. Choosing a stockiest with local UAE availability ensures faster delivery and better quality assurance.

Pricing for C276 and C22 alloys in the UAE depends on several factors—grade purity, diameter, production method (forged or cold-drawn), global metal rates, and mill certifications.

Engineers across the GCC often prefer these nickel-molybdenum alloys because they handle aggressive acids, seawater exposure, and extreme temperatures better than many Inconel grades. For desalination plants, marine structures, and chemical processing units, they offer stronger corrosion resistance and longer service life, which reduces maintenance costs in demanding UAE conditions.

Precision-machined components made from these alloys are widely used in offshore oil platforms, refinery equipment, chemical reactors, desalination units, and heat-intensive power plant systems. Their stability under pressure, chlorine-rich environments, and fluctuating temperatures makes them a preferred choice across UAE mega-projects and EPC contracts.

Selection depends on your operating environment—C276 is ideal for severe corrosion zones, C22 works well in chemical processing, B2 performs in reducing conditions, and X is designed for high-temperature applications. In the 21st century, engineers think beyond basic specs. With a future-focused mindset, engineers analyze the complete performance profile—everything from sizing to mechanical response to chemical stability—to ensure the material can thrive in demanding UAE sectors such as petroleum processing, marine engineering, and desalination technology. UAE suppliers can also provide guidance based on your temperature, media exposure, and pressure needs.