Stainless Steel Flanges Specification :

ASTM A182 / ASME SA182

Stainless Steel Flanges Specification :

ASTM A182 / ASME SA182

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Many types of steel flanges are offered by Kvn Steel Engg.And Co.one of the most used flanges are Duplex Steel Flanges. They are the famous manufacturer, supplier and stockiest of all types of steel flanges in all over the world. Stainless steel is highly durable and low-cost alloy. The flanges of Stainless steel are used widely as they have the properties which make it the unbeaten quality material.

Duplex Steel Flanges are hardened alloys and also exceptionally corrosion-resistant. Microstructures of this steel are consist of Ferrite and Austenite phases’ mixture. As a result, they consist of the features of both ferritic and austenitic stainless Steel. It has a high-strength and excellent resistance to corrosion. Duplex Stainless Steel Flanges have excellent intergranular corrosion. It has an outstanding high resistance to corrosion cracking stress even in sulfide and chloride environments.

ASTM A182 Duplex Stainless Steel S32205 Blind Flanges Exporter, SAF 2205 Long Weld Neck Flanges, Duplex S32205 Slip on Flanges, Duplex Steel S31803/S32205 Weld Neck Flanges, ASTM A182 Duplex Stainless Steel S31803/S32205 Flanges Supplier, Duplex Steel S31803 Flanges, Duplex S31803 Ring Type Joint - RTJ Flanges, Duplex S31803/S32205 Flanges Manufacturer in India.

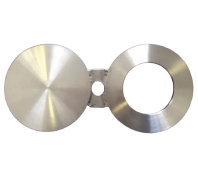

Duplex S32205 Spectacle Blind Flanges Dealer, SAF 2205 SORF Flanges, S32205 Duplex Stainless Steel Threaded Flanges Stockists, Duplex Stainless Steel UNS S32205 Plate Flanges, UNS S31803 Socket Weld Trader, DIN 1.4462 Pipe Flanges, ASME SA182 Duplex S31803/S32205 Flanges Supplier in India.

At the temperatures, more than 300 degree Celsius Duplex Steel Flanges is still protected from the corrosion causes embrittlement. Duct ability is excellent in low temperatures also. The fabrication work is done only through the tools assigned for materials of stainless steel. Before they used must be cleaned properly. It is done to save the stainless steel from the cross-contamination from the corroded metals.

These flanges can be hardened by the treatment of heat. Duplex Steel Flanges are application industries are; They are used in off-shore oil drilling companies, used in Aircraft exhaust manifolds, uses in petrochemicals, in power generation, in gas processing, in pharmaceuticals, uses in specialty chemicals, spiral welded tube for burner pipes and fuels, pharmaceutical equipment, heat exchangers, and also in seawater equipment. Double Steel Flanges are available in the many designs like slip-on, weld-neck, blind, threaded, lap joint, and socket weld.

The test certificate is according to the EN10204/31B. Material testing includes intergranular corrosion (IGC) test, flaring test, pitting resistance test, micro, and macro test, flattening test, positive material identification test, chemical analysis, hardness test, and mechanical testing such as tensile of area. The packaging is in wooden pallets and cases to avoid the damages of the material during its delivery and to maintain the trust of the customers.

| STANDARD | WNR. |

|---|---|

| Duplex S31803 / S32205 | 1.4462 |

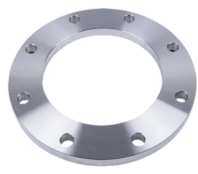

Duplex S31803/S32205 Slip On Flanges

Duplex Stainless Steel S31803 SORF Flanges, UNS S31803 / S32205 Slip On Flanges, DIN 1.4462 SORF Flanges, SAF 2205 Slip-on Raised Face Flanges

Duplex S31803/S32205 Weld Neck Flanges

ASME SA182 Duplex S32205 WNRF Flanges, ASTM A182 Duplex Stainless Steel S31803 Weld Neck Flanges, DIN 1.4462 Weld Neck Flanges, UNS S31803 Weld Neck Raised Face Flanges

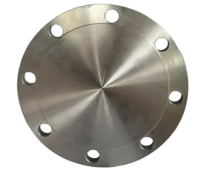

Duplex S31803/S32205 Blind Flanges

Duplex Stainless Steel ASTM A182 SAF 2205 Blind Flanges, UNS S31803 / DIN 1.4462 Blind Flanges, ASME SA182 Duplex S32205 BLRF Flanges, Duplex S31803/S32205 Blind Raised Face Flanges Supplier

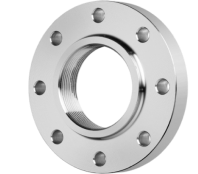

Duplex S31803/S32205 Threaded Flanges

DIN 1.4462 Threaded Flanges, UNS S31803 Screwed Flanges, ASME SA 182 Duplex Stainless Steel S32205 Threaded Flanges, ASTM A182 S31803/S32205 Duplex Threaded Flanges

Duplex S31803/S32205 Socket Weld Flanges

ASTM A182 2205 Duplex Stainless Steel Socket Weld Flanges, Duplex UNS S31803/ S32205 Socket Weld Flanges, Duplex DIN 1.4462 Socket Weld Flanges

Duplex S31803/S32205 Lap Joint Flanges

UNS S31803 Lap Joint Flanges, Duplex Stainless Steel S31803 Lap Joint Flanges, ASTM A182 2205 Duplex Lap Joint Flanges, ASME SA 182 Duplex S31803/S32205 Lap Joint Flanges

Duplex S31803/S32205 Ring Type Joint Flange

UNS S31803 Ring Type Joint Flange, ANSI B16.5 Duplex Stainless Steel S31803 RTJ Flanges, ASTM A182 2205 Duplex Steel Ring Type Joint Flanges, ASME SA 182 Duplex S31803/S32205 Ring Type Joint Flanges

Duplex S31803/S32205 Orifice Flanges

UNS S31803 Orifice Flanges, B16.36 Duplex Stainless Steel S31803 Orifice Flanges, ASTM A182 2205 Duplex Stainless Steel Orifice Flanges, ASME SA 182 Duplex S31803/S32205 Orifice Flanges

Duplex S31803 Long Weld Neck Flanges

UNS S32205 Long Weld Neck Flanges, Duplex Stainless Steel 1.4462 Long Weld Neck Flanges, ASTM A182 2205 Duplex Steel Long Weld Neck Flanges, ASME SA182 Duplex S31803/S32205 Long Weld Neck Flanges

Alloy 800/800H Long Weld Neck Flanges

UNS N08825 Long Weld Neck Flanges, Incoloy 2.4858 Long Weld Neck Flanges, ASTM B564 Incoloy 800 Long Weld Neck Flanges, ASME SB 564 Incoloy 800HT Long Weld Neck Flanges

Duplex S31803/S32205 Forged Flanges

UNS S32205 Forged Flanges, B16.5 Duplex Stainless Steel S31803 Forged Flanges, ASTM A182 2205 Duplex Steel Forged Flanges, ASME SA 182 Duplex S31803/S32205 Forged Flanges

Duplex S31803/S32205 Plate Flanges

UNS S31803 Plate Flanges, ANSI B16.5 Duplex Steel S31803 Plate Flanges, ASTM A182 2205 Duplex Stainless Steel Plate Flanges, ASME SA 182 Duplex S31803/S32205 Plate Flanges

Stainless Steel Flanges Specification :

ASTM A182 / ASME SA182

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

| Grade | Common Name | C% | Mn% | Si% | P% | S% | Cr% | Ni% | Mo% | N% |

|---|---|---|---|---|---|---|---|---|---|---|

| 2205 | S31803 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

| 2205 | S32205 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 |

| Tensile strength | 620MPa min | Density | 7,805kg/m3 |

|---|---|---|---|

| Yield strength | 450MPa mi | Elastic modulus | 200GPa |

| Elongation | 25% min | Mean coefficient of thermal expansion | |

|---|---|---|---|

| Brinell hardness | 293 HB max | 0-100oC | 13.7µm/m/oC |

| Rockwell hardness | 31 HR C max | 0-315oC | |

| SS 309 | SS 310 | SS 310 | |

|---|---|---|---|

| Density | 8.0 g/cm3 | 8.0 g/cm3 | 8.0 g/cm3 |

| Melting Point | 1455 °C (2650 °F) | 1454 °C (2650 °F) | 1454 °C (2650 °F) |

Our Duplex Steel S31803/S32205 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry