Cupro Nickel Sheets and Plates Specification :

ASTM B151 / ASME SB151

Cupro Nickel Sheets and Plates Specification :

ASTM B151 / ASME SB151

Dimension Standard :

JIS, AISI, ASTM, GB, DIN, EN, etc

Width :

1000mm, 1219mm, 1500mm, 1800mm, 90 / 100mm, 2500mm, 3000mm, 3500mm, etc

Length :

90 / 100mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Kvn Steel & Engg.Co ventures continuously strengthening its market position by providing a wide range of Copper Nickel 90/10 Sheets & Plates to its customers. We provide premium quality of sheets and plates to our customers.

Copper Nickel 90/10 Sheets & Plates are one of the most highly demanded sheets and plates in the industrial market. These plates and sheets come in different forms. Some of the examples are strip, flats, blank (circle), ring (flange), coils, rolls, foils, etc. there are also various types of sheets available like shim sheet, perforated sheets, and B.Q. profile. The sheets and plates also vary in their finishing like a hot rolled plate (HR), cold-rolled sheet (CR), SATIN (Met with plastic coated), etc. the sheets and plates also varies in thickness and further it can be customized according to the needs, preferences, and demand of the customers.

Cupro Nickel® Alloy 90/10 Perforated Sheets, Cu-Ni 90 / 10 Shim Sheets, ASTM B151 Copper Nickel 90/10 Coils Supplier, 90 / 10 Copper Nickel #4 Finish Plates, 90 / 10 Copper Nickel Chequered Plates Stockists, Cu-Ni Alloy 90 / 10 CR Sheets, ASTM B151 Cu-Ni 90 / 10 Sheets Exporter, Copper Nickel Alloy 90 / 10 Hot Rolled Plates, Copper Nickel Alloy ASTM B151 90 / 10 Plates, Cu-Ni 90/10 Sheets and Plates Manufacturer in India.

Due to the unique and excellent properties of Copper Nickel 90/10 Sheets & Plates are used for gas structures, power generation, offshore oil, desalination plants, shipbuilding, and repair. The sheets are also used as pump parts that are utilized for seawater services and also for some parts of machines and forged value. The plates come in use for powering steering tubes, brake lines, pressure vessels. The plates also come in use for condenser plates, break lines and distiller tubes.

ASTM B151 Cupro Nickel 90 / 10 Cold Rolled Sheets, Copper Nickel 90 / 10 Hot Rolled Plates, 90/10 Cupro Nickel Chequered Plates Stockists, DIN 2.0872 Plates, Cupro Nickel Alloy 90 / 10 2B Finish Plates, Cupro Nickel 90 / 10 #8 Mirror Finish Plates, UNS C70600 Strips, Cupro Nickel UNS C70600 Shim Sheets, Cu-Ni Alloy DIN 2.0872 Sheets Dealer, ASME SB151 Cupro Nickel 90 / 10 Sheets and Plates Supplier in India.

Copper Nickel 90/10 Sheets & Plates have long estimated life and are of premium quality. The Steel and plates also have resistance ability against cupric chloride, oxidizing acid chloride, seawater, brine, and formic acid. They have high end finishing and accurate dimensions. They are highly in demand as compared to other sheets and plates because they have high tensile strength, ductility, hardness, can withstand high temperatures and heavy loads without causing any damage.

To ensure its quality and standards the Copper Nickel 90/10 Sheets & Plates are tested and verified strictly. Some of the tests are the flattening test, hardness test, and mechanical test, etc. To prevent these pipes and sheets from any damage the best packaging method is adopted like wooden pallets, crates, etc.

| STANDARD | UNS | WNR. | EN | AFNOR |

|---|---|---|---|---|

| Cupro Nickel 90/10 | C70600 | 2.0872 | NiCr20CuMo | Z2NCUD31-20AZ |

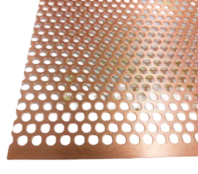

Cupro Nickel® Alloy 90/10 Perforated Sheets

Cupro Nickel 90 / 10 Perforated Sheets, UNS C70600 Perforated Sheets, DIN 2.0872 Perforated Sheets, ASME SB 251 Cupro Nickel Alloy 90 / 10 Perforated Sheets, Cu-Ni C70600 Perforated Sheets

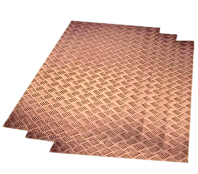

Cupro Nickel 90/10 Chequered Plates

ASME SB151 Cupro Nickel Alloy 90 / 10 Chequered Plates, ASTM B151 Cupro Nickel Alloy 90 / 10 Chequered Plates, DIN 2.0872 Chequered Plates, UNS C70600 Chequered Plates, Copper Nickel® Alloy 90/10 Checkered Plates

Cupro Nickel Alloy 90/10 Shim Sheets

Cupro Nickel ASTM B151 90/10 Shim Sheets, UNS C70600 / DIN 2.0872 Shim Sheets, ASME SB151 Cu-Ni 90/10 Shim Sheets, Cupro Nickel® Alloy 90 / 10 Shim Sheet, Cupro Nickel® Alloy 90 / 10 Shim Sheets, Cupro Nickel Alloy 90/10 Shim Sheets Supplier

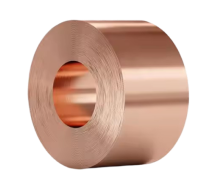

Cupro Nickel Alloy 90/10 Coils

DIN 2.0872 Coils, UNS C70600 Coils, ASME SB251 Cupro Nickel 90/10 Coils, ASTM B151 90/10 Cupro Nickel Alloy Coils

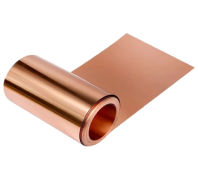

Cupro Nickel Alloy 90/10 Strips

ASTM B151 90/10 Cupro Nickel Strips, Cupro Nickel Alloy UNS C70600 Strips, Copper Nickel 90/10 Strips, Cupro Nickel Alloy 2.0872 Strips

Cupro Nickel Alloy 90/10 Foils

UNS C70600 Foils, Copper Nickel 90/10 Foils, ASTM B151 90 / 10 Copper Nickel Foils, Copper Nickel Alloy 90 / 10 Foils

Cupro Nickel Sheets and Plates Specification :

ASTM B151 / ASME SB151

Dimension Standard :

JIS, AISI, ASTM, GB, DIN, EN, etc

Width :

1000mm, 1219mm, 1500mm, 1800mm, 90 / 100mm, 2500mm, 3000mm, 3500mm, etc

Length :

90 / 100mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness :

0.3 mm to 120 mm

Form :

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing :

Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

Chemical Composition of Cupro Nickel 90/10 Sheets and Plates

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

|---|---|---|---|---|---|---|

| Cupro Nickel 90/10 | 88.6 | 1.0 max | 0.05 max | 9 - 11 max | 1.8 max | 1 max |

Mechanical Properties Of Cupro Nickel 90/10 Sheets and Plates

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Our Copper Nickel 90/10 Sheets and Coils Supplier are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry