Alloy 20 Flanges Specification :

ASTM B363 / ASME SB363

Alloy 20 Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

If your operations involve corrosive media, high temperature, or chemical-rich environments, Alloy 20 Flanges are one of the most reliable choices for long-lasting performance. Designed with excellent resistance against sulfuric acid, chloride stress corrosion, and harsh industrial chemicals, Alloy 20 offers a perfect balance of strength, durability, and cost-effectiveness. Whether you’re upgrading pipelines or sourcing material for a new project, choosing the right manufacturer and supplier makes all the difference.

Why Industries Prefer Alloy 20 Flanges

Alloy 20 (UNS N08020) is a nickel–iron–chromium alloy engineered for superior corrosion resistance. It’s widely used in:

Its ability to withstand acidic environments makes it ideal for Alloy 20 Flanges for Acids and Chemical Processing, ensuring leak-proof performance even under challenging conditions.

Types of Alloy 20 Flanges for Every Requirement

To support diverse industrial applications, you can choose from a complete range of Alloy 20 Industrial Flanges, including:

Every flange type is manufactured as per global standards like Alloy 20 ASTM B462, Alloy 20 ANSI B16.5 Flanges, Alloy 20 DIN Flanges, and Alloy 20 B462 Flanges for complete compliance and compatibility.

Alloy 20 Flanges Manufacturer & Global Supplier Network

When searching for a reliable Alloy 20 Flanges Manufacturer, it’s important to choose one that offers consistent quality, certified materials, and on-time delivery. Businesses can also explore options such as:

Whether you’re sourcing locally or internationally, you can find suppliers across major industrial markets:

If you’re searching online, many businesses use queries like Alloy 20 Flanges Supplier Near Me to identify trusted local vendors with quicker delivery timelines.

Applications in High-Temperature & Offshore Environments

Alloy 20 is engineered to perform reliably in challenging environments that expose materials to:

This makes it an excellent choice for Alloy 20 Flanges for Offshore Applications and Alloy 20 Flanges for High-Temperature Applications, delivering consistent performance and higher operational safety.

Buy Alloy 20 Flanges – What to Check Before Purchasing

Before you Buy Alloy 20 Flanges, consider the following:

✔ Material Grade

Ensure the material meets Alloy 20 UNS N08020 requirements.

✔ Standards & Certifications

Always request Alloy 20 Flanges with Test Certificates for authenticity.

✔ Size & Pressure Ratings

Choose flanges that match your pipeline and operational needs.

✔ Application Fit

For corrosive media or high-pressure environments, pick the appropriate flange type.

Whether you’re exploring Alloy 20 Flanges for Sale or requesting a Alloy 20 Flanges Price List, selecting the right supplier ensures reliable, long-term performance.

Why Choose Alloy 20 for Corrosive Environments?

Many industries consider this alloy the Best Alloy 20 Flanges Supplier for Corrosive Environments because:

This combination of durability, cost-efficiency, and corrosion resistance makes Alloy 20 a preferred choice for mission-critical applications.

| STANDARD | UNS | WNR. | EN | AFNOR |

|---|---|---|---|---|

| Alloy 20 | N08020 | 2.4660 | NiCr20CuMo | Z2NCUD31-20AZ |

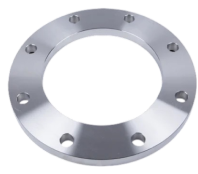

Carpenter 20 Slip On Flanges

Alloy 20 SORF Flanges, UNS N08020 Slip On Flanges, DIN 2.4660 SORF Flanges, ASME SB 363 Alloy 20 Slip-on Raised Face Flanges

Alloy 20 Weld Neck Flanges

ASME SB363 Alloy 20 WNRF Flanges, ASTM B363 Alloy Gr 20 Weld Neck Flanges, DIN 2.4660 Weld Neck Flanges, UNS N08020 Weld Neck Raised Face Flanges

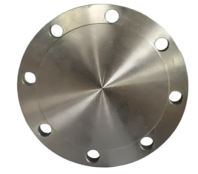

Carpenter 20 Blind Flanges

ASTM B363 Alloy 20 Blind Flanges, UNS N08020 / DIN 2.4660 Blind Flanges, ASME SB363 Alloy 20 BLRF Flanges, Gr 20 Alloy Blind Raised Face Flanges Supplier

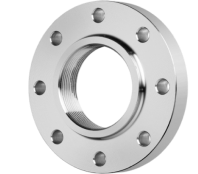

Alloy 20 Threaded Flanges

DIN 2.4660 Threaded Flanges, UNS N08020 Screwed Flanges, ASME SB 363 Alloy Gr 20 Threaded Flanges, ASTM B363 Alloy 20 Threaded Flanges

Carpenter 20 Socket Weld Flanges

ASTM B363 Alloy 20 Socket Weld Flanges, Alloy UNS N08020 Socket Weld Flanges, Alloy DIN 2.4660 Socket Weld Flanges

Alloy 20 Lap Joint Flanges

UNS N08020 Lap Joint Flanges, Alloy 20 Lap Joint Flanges, ASTM B363 Carpenter 20 Lap Joint Flanges, ASME SB363 Alloy 20 Lap Joint Flanges

Alloy 20 Ring Type Joint Flange

UNS N08020 Ring Type Joint Flange, ANSI B16.9 Alloy 20 RTJ Flanges, ASTM B363 Alloy 20 Ring Type Joint Flanges, ASME SB363 Alloy 20 Ring Type Joint Flanges

Alloy 20 Orifice Flanges

UNS N08020 Orifice Flanges, B16.36 Alloy 20 Orifice Flanges, ASTM B363 Alloy 20 Orifice Flanges, ASME SB 363 Carpenter 20 Orifice Flanges

Alloy 20 Long Weld Neck Flanges

UNS N08020 Long Weld Neck Flanges, Alloy 2.4660 Long Weld Neck Flanges, ASTM B363 Alloy 20 Long Weld Neck Flanges, ASME SB 363 Alloy 20 Long Weld Neck Flanges

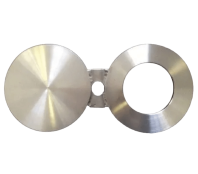

Alloy 20 Spectacle Blind Flanges

UNS N08020 Spectacle Blind Flanges, ANSI / ASME B16.9 Alloy 20 Spectacle Blind Flanges, ASTM B363 Alloy 20 Spectacle Blind Flanges, ASME SB 363 Alloy 20 Spectacle Blind Flanges

Alloy 20 Forged Flanges

UNS N08020 Forged Flanges, B16.9 Alloy 20 Forged Flanges, ASTM B363 Alloy 20 Forged Flanges, ASME SB363 Alloy 20 Forged Flanges

Alloy 20 Plate Flanges

UNS N08020 Plate Flanges, ANSI B16.9 Alloy 20 Plate Flanges, ASTM B363 Alloy 20 Plate Flanges, ASME SB363 Alloy 20 Plate Flanges

Alloy 20 Flanges Specification :

ASTM B363 / ASME SB363

Dimension Standard :

ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard :

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size :

1/2" (15 NB) to 48" (1200NB)

Class / Pressure :

150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type :

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges :

DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges :

JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges :

BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

Chemical Composition of Alloy 20 Flanges

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

Mechanical Properties Of Alloy 20 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi - 35,000, MPa - 241 | 30 % |

Our Alloy 20 Flanges are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry

Get clear answers to common queries about our steel products, services, and delivery processes.

Alloy 20 Flanges are high-performance flanges made from a corrosion-resistant nickel–iron–chromium alloy designed for chemical, petrochemical, and industrial processing environments. Industries prefer them because they deliver exceptional strength, resistance to sulfuric acid, and stability under harsh operating conditions. Many buyers source them from a Trusted Supplier of Alloy 20 Industrial Flanges to ensure long-lasting performance.

When selecting an Alloy 20 Flanges Manufacturer, check for industry certifications, global standards compliance, and production capability. A reputable manufacturer will provide Alloy 20 Flanges with Test Certificates, ensuring authenticity and traceability. Look for suppliers with strong experience in High-Performance Alloy 20 Pipe Flanges, especially if your project involves corrosive or high-temperature media.

Businesses commonly source these products from regions known for strong metallurgical capabilities, such as an Alloy 20 Flanges Supplier in India or an Alloy 20 Flanges Supplier in UAE. Both regions offer competitive pricing, export-quality standards, and a wide range of Alloy 20 Pipe Flanges Supplier options for refineries, chemical plants, offshore units, and maintenance contractors.

Yes. Many industries choose Alloy 20 Flanges for High-Temperature Applications because the alloy maintains mechanical strength and corrosion resistance even when exposed to extreme heat. This makes them suitable for reactors, boilers, heat exchangers, and high-pressure systems where durability and reliability are critical.

Before purchasing, verify the flange type, size, pressure rating, and material grade. Always ensure that your Alloy 20 Industrial Flanges come from a Trusted Supplier of Alloy 20 Industrial Flanges and are supplied with complete documentation like heat numbers, MTCs, and compliance reports. If you are sourcing internationally, compare suppliers from India and UAE for fast delivery and competitive pricing.