Specifications :

ASTM B366 / ASME SB366

Specifications :

ASTM B366 / ASME SB366

Dimensions :

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size :

Seamless Butt Weld Fittings : 1/2" - 10" | Welded Butt Weld Fittings : 1/2" - 48"

Schedule :

SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75

Alloy 20 Buttweld Fittings are engineered using a corrosion-resistant austenitic alloy primarily composed of nickel, chromium, iron, and copper. Recognized for their superior resistance to sulfuric acid and other aggressive media, these fittings provide reliable long-term performance in highly corrosive environments. Designed to meet the stringent demands of piping systems that require tight, leak-free connections, these fittings are manufactured in compliance with international standards such as ASTM B366 and ASME B16.9. The controlled composition of Alloy 20—featuring approximately 35% nickel, 20% chromium, and 3-4% copper—enhances its resistance not only to sulfuric acid but also to chloride stress corrosion cracking and pitting. These characteristics make it a strong contender over traditional stainless steels in demanding chemical processing conditions.

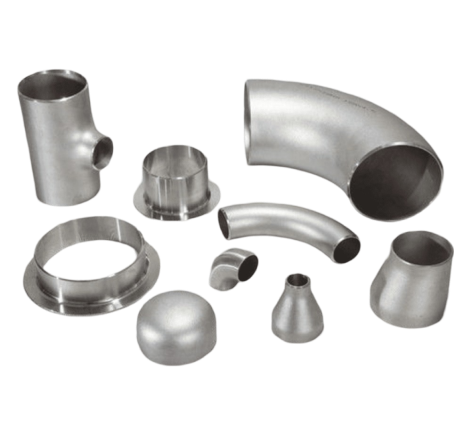

The fittings are available in a comprehensive range of configurations including elbows, tees, reducers, crosses, and caps, each designed for optimal flow dynamics and mechanical strength. They are typically used in welded pipe systems, ensuring reduced turbulence and pressure loss compared to flanged connections. Precision forging and seamless construction ensure dimensional accuracy, structural integrity, and uniform wall thickness, which are essential for high-pressure and high-temperature operations. The reduced carbon composition of Alloy 20 minimizes the risk of carbide formation during welding, enhancing weld quality while preserving its excellent corrosion resistance. Rigorous testing—such as PMI, hydrostatic pressure tests, ultrasonic examination, and radiographic analysis—is conducted to verify mechanical properties and compliance before dispatch.

Applications of Alloy 20 Buttweld Fittings

Alloy 20 Buttweld Fittings are widely utilized in piping networks that require consistent resistance to acidic and chlorinated environments. Their most prominent use is in the chemical processing industry, especially where handling sulfuric acid, nitric acid, phosphoric acid, and other strong oxidizing agents is part of the daily operation. The fittings are also crucial in food and beverage processing facilities, where they provide sanitary connections that resist contamination and corrosion caused by cleaning chemicals and acidic food substances. Furthermore, these fittings are well-suited for use in pharmaceutical manufacturing plants, offering excellent resistance to organic and inorganic acids while ensuring product purity through smooth internal finishes.

In power generation, particularly in nuclear and thermal plants, Alloy 20 fittings are integrated into condensate and feedwater systems due to their resistance to localized corrosion and their ability to withstand thermal cycling. They are also used in pickling equipment, heat exchangers, and scrubbers within pollution control systems. In offshore and marine environments, Alloy 20 Buttweld Fittings are deployed in ballast and bilge systems, desalination units, and piping exposed to brine and saline conditions. Their copper content helps reduce biofouling and minimizes maintenance requirements. Whether it's for transporting aggressive chemicals or ensuring long-term durability under high mechanical stress, these fittings deliver unmatched performance and longevity.

Industry Use and Supply Regions

The versatility of Alloy 20 Buttweld Fittings has made them a preferred choice across various industries, including chemical and petrochemical plants, food and beverage manufacturing, marine engineering, pharmaceuticals, power generation, and wastewater treatment facilities. Their exceptional resistance to corrosion, ease of fabrication, and adaptability to diverse process conditions ensure dependable performance in both static and dynamic systems. Industries operating under strict regulatory frameworks prefer Alloy 20 due to its compliance with safety, quality, and environmental standards. This alloy provides a strategic material advantage in sectors where equipment reliability is directly tied to operational efficiency and safety compliance.

Our supply capabilities extend to key industrial and infrastructure markets, particularly in India, the United Arab Emirates (UAE), the Kingdom of Saudi Arabia (KSA), Kuwait, Qatar, the Sultanate of Oman, Iran, and Iraq. These regions are witnessing robust growth in energy, petrochemical, and water treatment projects—sectors where Alloy 20 fittings are increasingly becoming integral. From EPC contractors in Abu Dhabi to oil refineries in Dammam and pharmaceutical plants in Hyderabad, we support businesses with timely, high-quality deliveries backed by documentation and compliance certifications. Every batch is thoroughly inspected and traceable, ensuring our clients across these regions receive durable and dependable buttweld fittings that meet both application-specific and environmental standards.

| STANDARD | UNS | WNR. | EN | AFNOR |

|---|---|---|---|---|

| Alloy 20 | N08020 | 2.4660 | NiCr20CuMo | Z2NCUD31-20AZ |

Alloy 20 Elbow

Alloy 20 90 Deg Elbow, Alloy 20 45 Deg Elbow, UNS N08020 180 Deg Elbow, DIN 2.4660 SR Elbow, B16.9 Alloy 20 90 Degree Short Radius Elbow, Alloy 20 45 Deg Long Radius Elbow

Alloy 20 Tee

ASME B16.9 Alloy 20 Equal Tee, UNS N08020 Pipe Tee, Alloy 20 Butt weld Tee, ASME SB366 Alloy 20 Reducing Tee manufacturer, DIN 2.4660 Unequal Tee, Alloy 20 Straight Tee

Alloy 20 Eccentric Reducer

ASTM B366 Alloy 20 Eccentric Reducer Supplier, B16.9 Alloy 20 Eccentric Reducer, Alloy UNS N08020 Eccentric Reducers, DIN 2.4660 Eccentric Reducer

Alloy 20 Concentric Reducer

ANSI B16.9 Alloy 20 Concentric Reducer Supplier, ASME SB366 Alloy 20 Concentric Reducer, UNS N08020 Concentric Reducers, DIN 2.4660 Concentric Reducer

Alloy 20 Long Stub End

ANSI / ASME B16.9 Alloy 20 Long Stub End Supplier, ASTM B366 / ASME SB 366 Alloy 20 Lap Joint Stub End, Alloy 20 UNS N08020 Long Stub Ends, DIN 2.4660 Long Stub End

Alloy 20 Short Stub End

ASTM B366 / SB366 Alloy 20 Short Stub End Supplier, Incoloy® alloy 20 ASME B16.9 Short Stub Ends, Alloy UNS N08020 Short Stub Ends, DIN 2.4660 Short Stub End

Alloy 20 Cap

ASTM B366 / SB366 Alloy 20 Pipe Cap Supplier, ASME B16.9 Alloy 20 End Pipe Cap, Alloy UNS N08020 Pipe End Cap, Alloy 20 Buttweld Cap, DIN 2.4660 End Cap

Alloy 20 Cross

ASTM B366 / ASME SB366 Alloy 20 Equal Cross, ASME B16.9 Alloy 20 Buttweld Cross, Alloy UNS N08020 Unequal Cross, DIN 2.4660 Reducing Cross

Alloy 20 Pipe Bend

ASME SB 366 Alloy 20 Pipe Bend Exporter, B16.9 Alloy 20 Piggable Bend, Alloy UNS N08020 U Bend, DIN 2.4660 Long Radius Bend, Alloy 20 Buttweld Bend Supplier

Specifications :

ASTM B366 / ASME SB366

Dimensions :

ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Size :

Seamless Butt Weld Fittings : 1/2" - 10" | Welded Butt Weld Fittings : 1/2" - 48"

Schedule :

SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75

Bending Radius :

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Type :

Seamless / ERW / Welded / Fabricated

Thickness :

20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc.

Chemical Composition of Alloy 20 Seamless and Welded Pipe Fittings

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Fe | Mo | P |

|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 20 | 0.07 max | 2.00 max | 1.00 max | 0.035 max | 3.00 – 4.00 | 32.00 – 38.00 | 19.00 – 21.00 | 29.85 min* | 2.00 – 3.00 | 0.045 max |

Mechanical Properties Of ASME SB366 Alloy 20 Buttweld Pipe Fittings

| Element | Alloy 20 |

|---|---|

| Density | 8.1 g/cm3 |

| Melting Point | 1443 °C (2430 °F) |

| Tensile Strength | Psi -80,000, MPa -551 |

| Yield Strength (0.2%Offset) | Psi - 35,000, MPa - 241 |

| Elongation | 30 % |

Our Alloy 20 Buttweld Fitting Supplier are used in a wide range of applications and various industries. Below are a few of them:

Application Industries

Aerospace Industry

Food Processing Industry

Pulp & Paper Indusry

Energy Industry

Pharmaceuticals Industry

Power Plant Industry

Chemical Industry

Oil and Gas Industry

Get clear answers to common queries about our steel products, services, and delivery processes.

sefw vrv

dewv fve dwvc wd d e